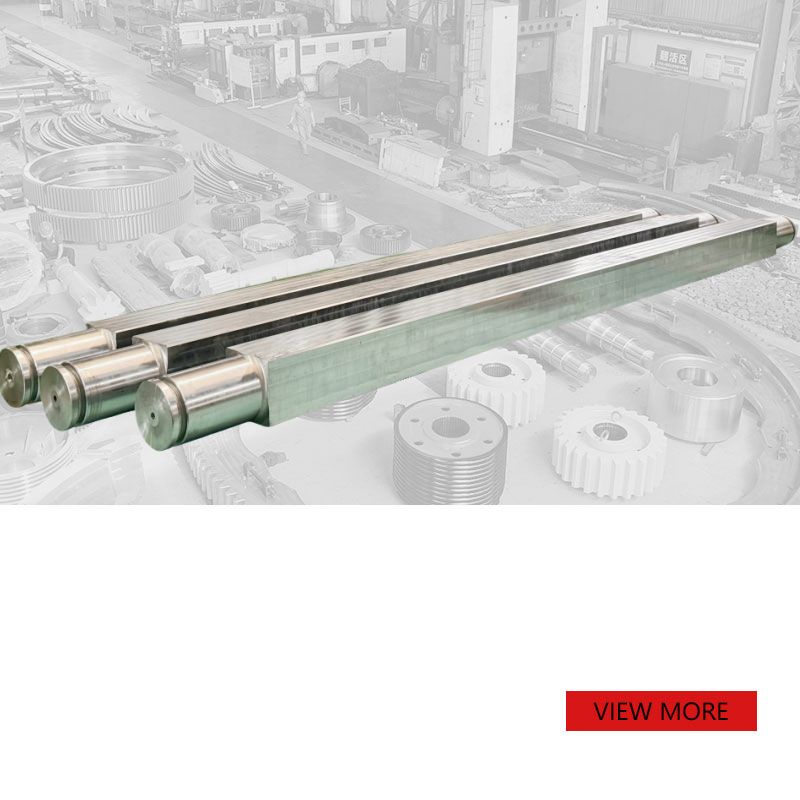

Customized Large Forging connecting shaft for dragline/Walking excavator

PRODUCT PARAMETERS

Description

Overview & Application of Dragline Track connecting shaft

Dragline are usually equipped with crawler walking devices that allow the machine to move on uneven ground. The connecting shaft can be used to transfer power from the drive motor to the crawler wheel, ensuring that the excavator can travel or steer smoothly.

For these heavy construction machinery, the design of the connecting shaft must consider high strength, wear resistance and good fatigue resistance, because they need to withstand extreme stress and harsh working environments.

Production process of Dragline Track connecting shaft

Forging

A more common method for this type of component, where heated metal is pressed or hammered into shape. This process increases the strength and durability of the shaft.

Machining

After forging, the shaft undergoes machining to achieve precise dimensions and surface finishes. Operations may include turning, milling, drilling, and grinding.

Heat Treatment

The shaft is subjected to heat treatment processes such as quenching and tempering to improve hardness and toughness.

Precision Machining

Manufactured to tight tolerances to ensure proper fit and alignment with other track components, minimizing wear and tear on the entire track assembly.

Inspection and Quality Control

Non-destructive testing methods such as ultrasonic testing, magnetic particle inspection are used to check for defects.

Package of Track connecting shaft

Use anti-rust oil or anti-rust agent to apply to the surface of the connecting shaft to provide short-term anti-corrosion protection.

Wrap plastic film or special rust-proof paper to further prevent moisture intrusion.

Customize robust fumigation-free plywood boxes according to the specific size and shape of the connecting shaft. The steel frame for forklift operation is welded on the outside of the wooden box.

FAQs of Track connecting shaft

1.What module of Shaft can you produce? –8-120

2.What is the accuracy grade you can achieve? –6-8

3.What kind of payment terms do you have? –T/T & L/C

4.Do you accept third party inspection?–Yes.

Contact us