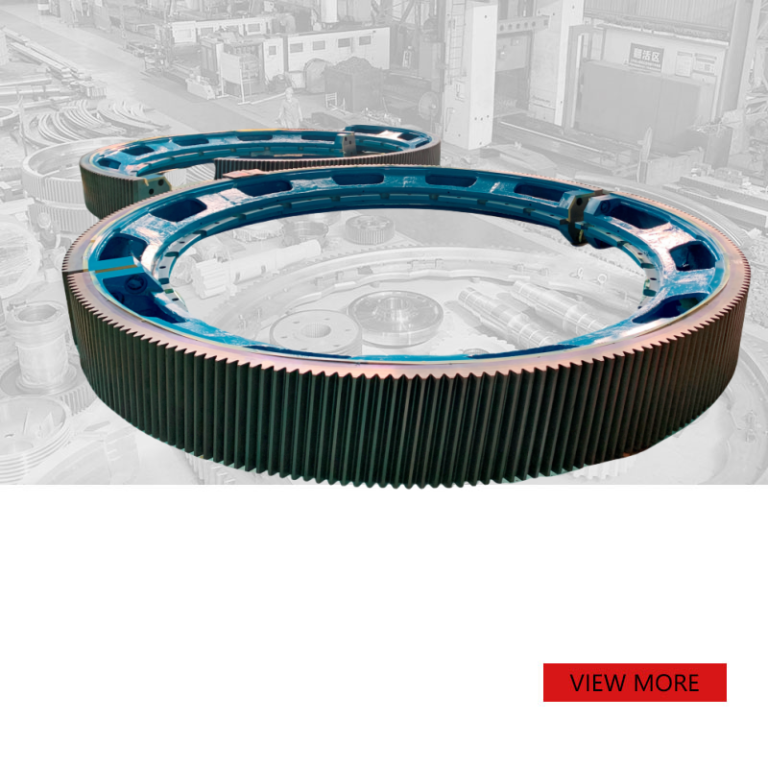

Spur gear forging high quality large diameter pinion spur gear

PRODUCT PARAMETERS

Description

Overview of Spur Gear

Spur gear are a type of cylindrical gear with straight teeth that are parallel to the axis of rotation. They are one of the most common types of gears used in mechanical devices and machinery for transmitting power between two parallel shafts.

Production process of Spur Gear

Forging

The blank is heated to a plastic state and then die forged on a forging hammer or press to form the rough shape of the gear. Forging can improve the internal structure of materials and improve mechanical properties.

Rough Machining

Gear roughing is an important step to prepare for subsequent finishing, which mainly involves the preliminary forming of the outer circle, the inner hole and the end face.

-The outer circle and inner hole are machined by lathe or milling machine to make their dimensions close to the requirements of the finished product; At the same time, ensure that the two ends are parallel and perpendicular to the axis, usually by turning or milling process.

– Tooth shape, hobbing is the most common method, which uses a rotating hob to engage with the blank and cut the tooth groove one by one, which is suitable for mass production. For gears with complex structures or limited space, a gear shaper machine is used, where a single-blade cutter reciprocates to form a tooth shape. Through these steps, the gear can obtain a preliminary shape and lay the foundation for fine machining.

Heat treatment

Quenching and tempering are usually included to obtain the desired balance of hardness and toughness, ensuring that the gear has sufficient strength and wear resistance.

Tooth shape processing

Gear hobbing/shaper: Use special machine tools (such as gear hobbing or shaper) to process the tooth shape of the gear. Hobbing is suitable for mass production, while shaper is more suitable for small batches or complex shapes of gears.

Shaving/honing: In order to improve the precision and smoothness of the tooth surface, finishing methods such as shaving or honing can be used.

Finishing

Precision turning or grinding of the outer diameter, inner hole and end face of the gear to ensure the accuracy of the assembly size.

Surface treatment

Galvanizing, chrome plating, blackening or other anti-corrosion treatments may be performed, as well as surface hardening treatments such as nitriding, carburizing, etc., to enhance the corrosion and wear resistance of the gear.

Package of Spur Gear

Oiling or Coating: Applying a thin layer of rust-preventative oil or another protective coating can shield the surface from moisture and contaminants.

Packing: fumigation-free wooden case customized according to product size. If necessary, a steel frame will be welded to the outside of the wooden box to assist the operation of the forklift truck.

FAQs of Spur Gear

1.What module of gear can you produce? –8-120

2.What is the accuracy grade you can achieve? –6-8

3.What kind of payment terms do you have? –T/T & L/C

4.Whether to provide samples? –No

Contact us