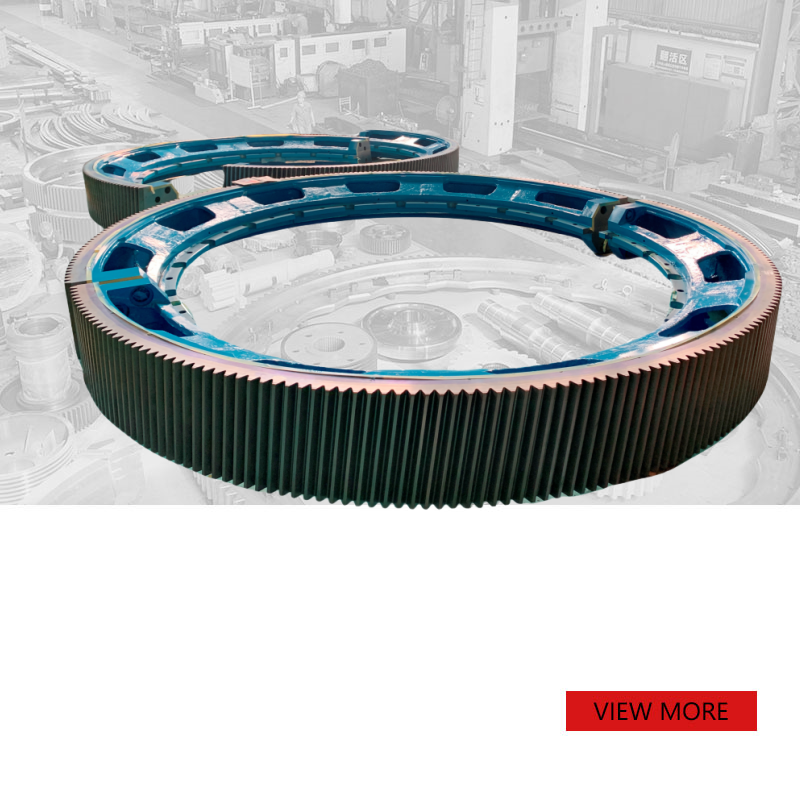

Custom 35CrMo Ball mill Casting Segment Girth Gear

PRODUCT PARAMETERS

Description

一. Company instruction

– 40+ years prodcution experience

– 2 factories and 5 workshops

-50+ Sets of equipment ( Including 6 sets of well-type elecric furnaces)

– 40+ patments

– 50+ countries and regions

二. Production Description

We can produce casting/forging/segment girth gears. (2/4/6/8/12 segments, etc)

| Module | 8-120 |

| Material | Cabon steel,Alloy steel |

| Gear profile | Spur gear/Helical gear |

| Structure | Forging/Casting/Forging+Welding |

| Grade | 6-9 |

| Diameter | Max. 16 meters (Integrated whole circle) |

Used in rotary kilns, ball mills and dragline excavators

三.Production process

- Make inspection model, modeling

2.After casting, keep the heat, clean the sand, cut the riser, and check the appearance dimensions.The castings were annealed to remove the stress and cooled to room temperature.

Surface polishing, shot blasting, check for casting defects, if any, according to the repair standards

3.Rough machining & UT

Roughing all finished surfaces and reserving heat treatment allowance according to the drawing process

4.QT

We will choose the heat treatment method according to the product characteristics

5. Semi-finished maching,matching and closing

6. Hobbing

Carring out the hobbing to the girth gear

7.Finished -machining,matching and closing

Finished machining according to the drawing, matching and closing

8.Rust proof, spray paint and packaging

四. FAQs

- What kind of packing do you have? –Our packing is suitable for export, usually plywood cases.

- Can you issue the drawings?–We can according to customer’s parameters to issue the drawings.

- Do you accept third party inspection?–Yes.

- What’s your payment terms?–T/T & L/C

- What’s your ship method?– By sea. By rail. By air.

REQUEST A QUOTE

RELATED PRODUCTS

35CrMo Forging Mining large dimeter 12 Segment Arc Tooth

Customized large modulus pinion for rotary kiln

Forging high quality Large diameter Bevel gear

Non-standard customized large diameter 4 large segmented ring gear

forged steel pinion helical gear