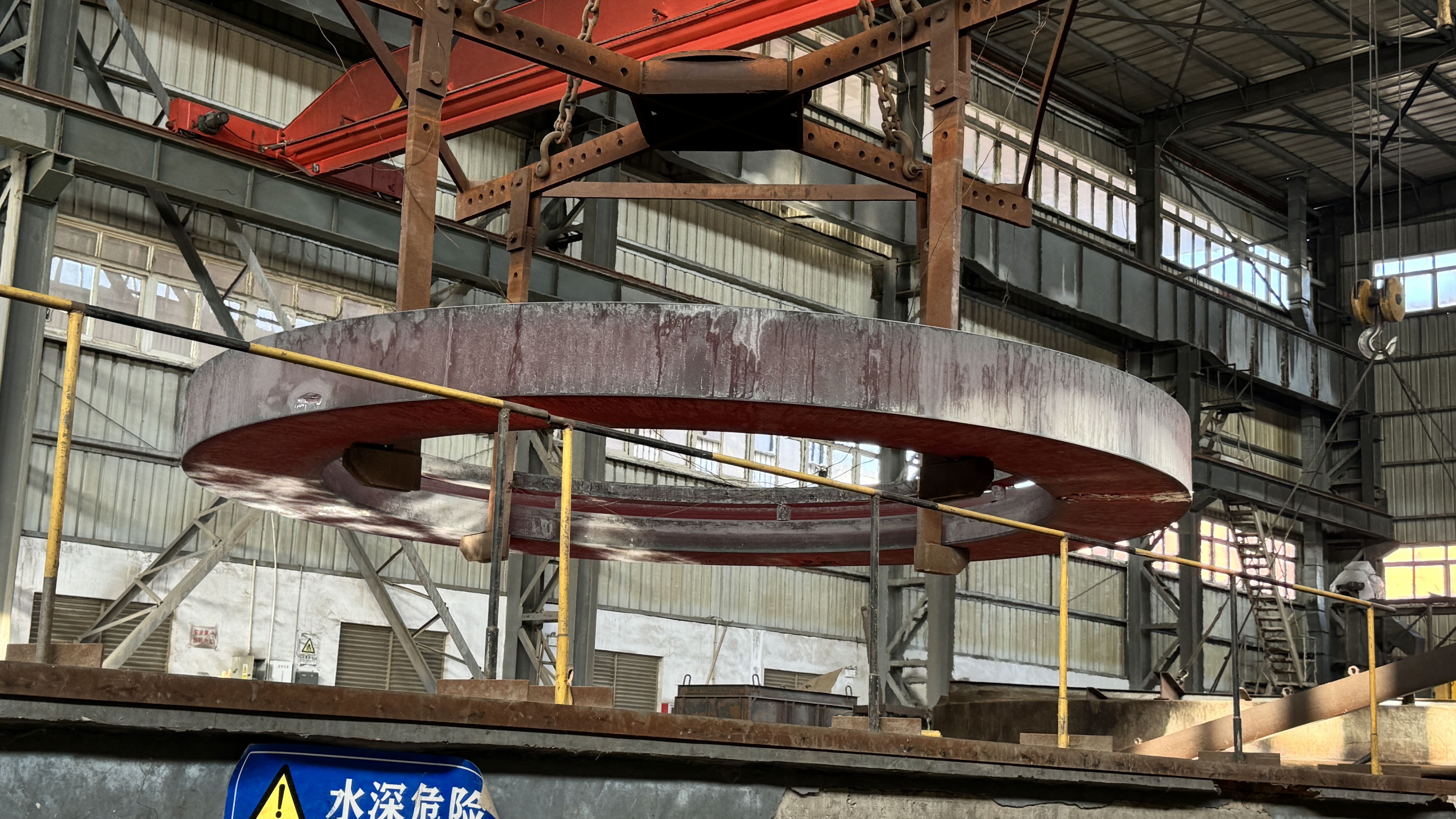

Forged large diameter ring gear for Rotary Kiln

PRODUCT PARAMETERS

Description

The rotary kiln ring gear is a very important component in the rotary kiln equipment. It is mainly used to transmit power so that the rotary kiln can rotate and work normally.

The production process of large ring gear of rotary kiln:

1: Material preparation:

First, you need to select suitable materials, usually high-strength alloy steel and other materials, which have good mechanical properties and wear resistance.

Carbon steel: such as 45 steel, which is a commonly used medium carbon steel with good comprehensive mechanical properties. Its hardness and strength can be improved through heat treatment. It is suitable for the large gear ring of rotary kiln under general working conditions.

Low alloy steel: such as 35SiMn, 35CrMo, 40Cr, etc. This type of steel contains a small amount of alloying elements, which can significantly improve the material’s hardenability, wear resistance and fatigue strength, and is suitable for occasions with higher requirements.

Special alloy steel: For particularly harsh working conditions, it may be necessary to use higher performance special alloy steels, such as ZG42CrMo, ZG35SiMn, etc., which have excellent wear resistance, impact resistance and heat resistance.

2: Forging:

The selected material is heated to a certain temperature and then forged. Pressure is applied to the material through a forging press to form it into a rough shape. This step is very important for removing defects inside the material and improving the material structure.

3: Heat treatment:

After forging is completed, the large ring gear blank needs to be heat treated, including quenching, tempering and other processes, to improve its hardness and strength while ensuring a certain toughness.

4: Rough processing:

After heat treatment, use lathes and other mechanical equipment to perform preliminary processing on the large gear ring to process its external dimensions to a size close to the design requirements.

5: Finishing:

On the basis of rough machining, further fine machining is carried out, including tooth shape cutting, etc. to ensure that the accuracy of the large ring gear reaches the design standard.

6: Surface treatment:

In order to enhance the wear resistance and corrosion resistance of the large gear ring, it is usually necessary to perform surface treatment on it, such as surface hardening, painting, etc.

7: Inspection and testing:

Finally, conduct a comprehensive quality inspection on the processed large ring gear, including dimensional inspection, flaw detection inspection, etc., to ensure that the product has no defects, and conduct necessary load tests to verify its performance.

How to prevent early damage to the large ring gear?

1: Material selection and heat treatment:

Select high-strength, wear-resistant alloy steel as the manufacturing material, and use appropriate heat treatment (such as quenching and tempering) to improve its hardness and toughness, thereby enhancing fatigue resistance.

2: Optimized design:

Consider stress concentration issues during the design phase, use smooth transition designs to disperse stress as much as possible, and avoid sharp corners or sudden changes in structures.

Use tools such as finite element analysis (FEA) to predict potential high stress areas and strengthen the design in these areas.

3: Precision processing and assembly:

Ensuring the machining accuracy of the large ring gear and its mating parts (such as pinions), especially the tooth profile accuracy, is very important to reduce additional stress during operation.

During the installation process, accurate alignment must be ensured to avoid excessive local wear caused by misalignment.

4: Effective lubrication:

Using the right lubricant and changing the lubricant regularly according to the equipment manufacturer’s recommendations can significantly reduce friction and wear by maintaining good lubrication conditions.

Check the effectiveness of the lubrication system regularly to ensure that there is sufficient oil and no contamination.

5: Regular inspection and maintenance:

Establish a comprehensive inspection and maintenance plan, and regularly conduct visual inspections, flaw detection, and wear assessments on the ring gear.

Repair minor problems found in a timely manner to prevent them from turning into serious failures.

6: Control the working environment:

Minimize the entry of dust and particles into the working area of the gear ring, as these impurities will accelerate wear.

Maintain a suitable working temperature. Too high or too low temperature may affect material properties and cause early damage.

7: Reasonable operation:

Avoid overloading, operate the equipment according to design parameters, and reduce unnecessary shock and vibration.

The starting and stopping process is smooth, avoiding instantaneous high load caused by sudden braking or rapid starting.