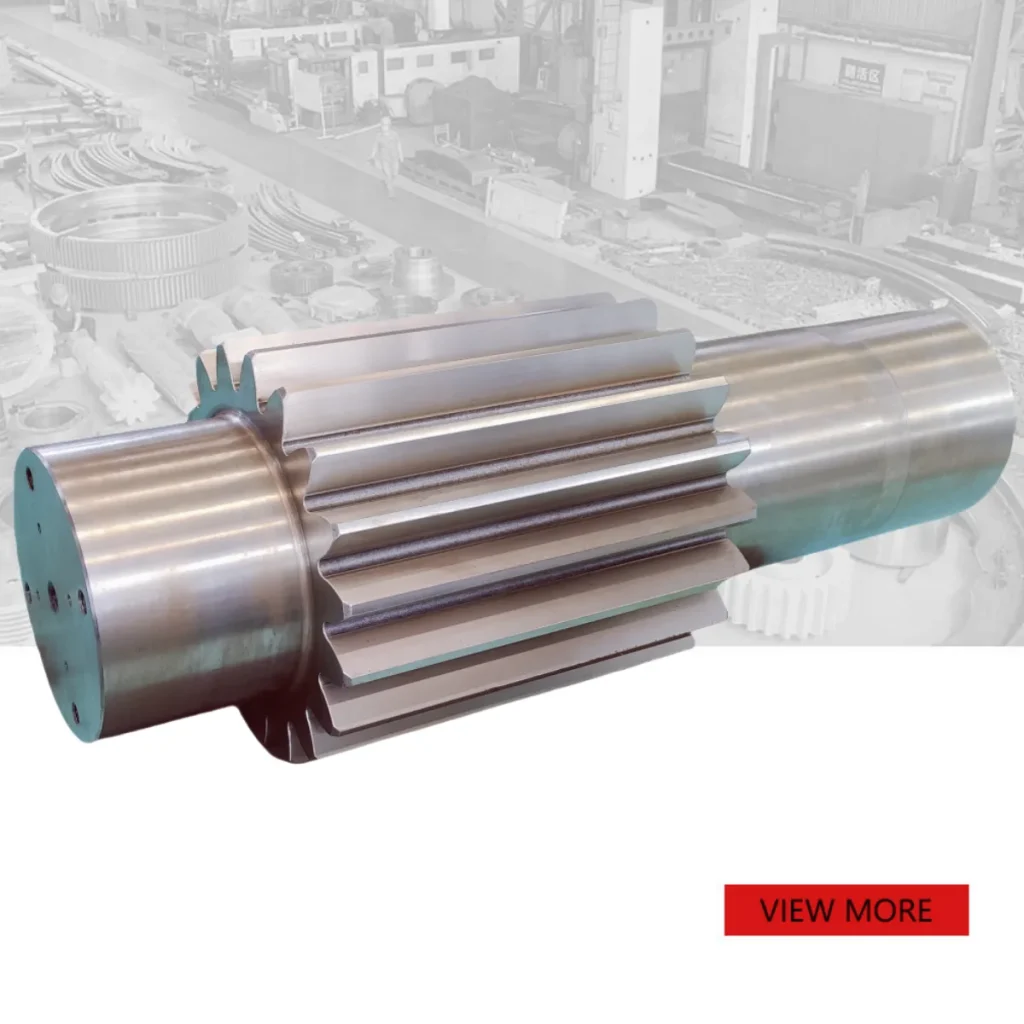

Customized non-standard Large module gear shaft transimission parts

PRODUCT PARAMETERS

Description

一.Description

| Material | Carbon steel/Alloy steel |

| Module | 8-120 |

| Accuracy | 6-8 |

| Surface treatment | Surface hardening/Surface carburizing |

| Gear profile | Straight/Helical |

| Pressure | 20° |

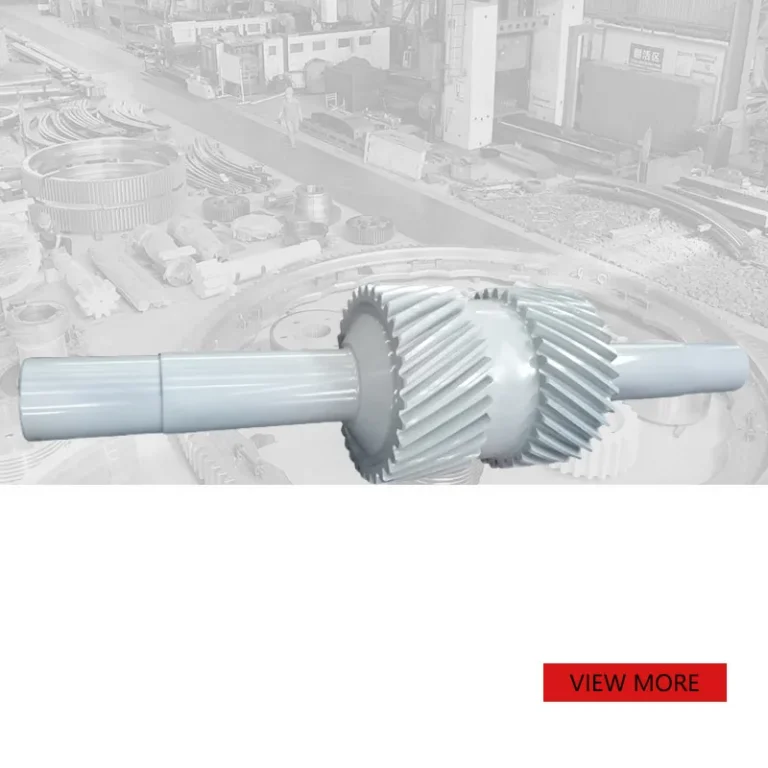

二.Usage for gear shaft

Large module gear shaft are usually used in mechanical transmission systems that need to transmit higher power and withstand higher loads. They can be found in a variety of industrial sectors, including but not limited to mining equipment, ball mills, rotary kilns, the metallurgical industry, wind power generation and other industries. The large module means that the gear has a large tooth thickness and a strong load carrying capacity, so it is suitable for these occasions that require strong toughness and reliability.

三.Production process for gear shaft:

1.Forging

The forged gear shaft can improve the strength and toughness of the product, reduce defects compared with casting, ensure better dimensional accuracy and surface finish, and the forged gear shaft usually has a good response to heat treatment (such as quenching, tempering, etc.), which can further improve its mechanical properties

2.Rough machining

Rough machining of large module gear shaft not only affects the quality and efficiency of subsequent finishing, but also directly relates to the performance, cost and service life of the final product. For example, improving production efficiency, improving stress distribution, discovering potential defects, and optimizing heat treatment effects lay the foundation for subsequent finishing.

3.UT

Through the ultrasonic test of the gear shaft, it can detect whether the internal defects exceed the standard, ensure the integrity of the internal structure, improve the safety of the product, and extend the service life of the product.

4.Heat treatment

Heat treatment is a key procedure in the whole production process. Our company be honored with the large mold heat treatment engineering technology center of Luoyang city.Our heat treatment workshop has 6 sets of electric furnace, the deepest one is 9 meters, the largest one diameter is 5.5 meters, the crane 50 tons, and our workshop bearing capacity can reach 100 tons.

5.Finish-machining

Finish-machining not only improves the performance and life of the gear shaft, but also ensures its reliability and efficiency in practical applications. For example, improve dimensional accuracy, improve surface finish, ensure shape and position tolerances, enhance fatigue resistance, meet assembly requirements, optimize meshing quality, and reduce maintenance needs.

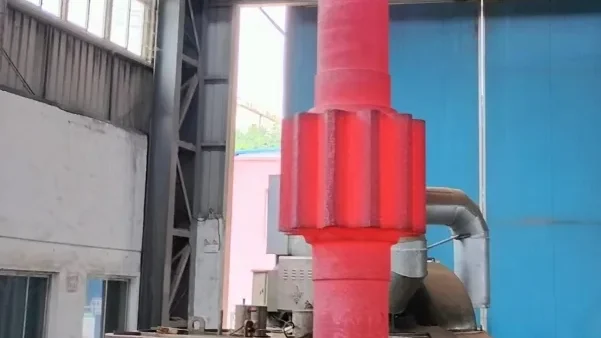

6.Inspection & Delivery

Inspect the products runs through all stages of design, manufacturing, installation and maintenance. Through the inspection of the system, the quality of the gear shaft (including dimensional accuracy, shape tolerances, surface finish), performance and safety (such as internal defects, material fatigue) can be ensured, thus improving the reliability of the entire mechanical system.

When the product is qualified, we’ll issue the product certificate for the customer, and then the product is painted and shipped.

四.FAQ

1.Are you subject to third-party testing?-Yes

2.Is it possible to issue drawings?–Yes

3. What’s your payment terms?–T/T & L/C

4. What’s your ship method?– By sea. By rail. By air.

Contact us