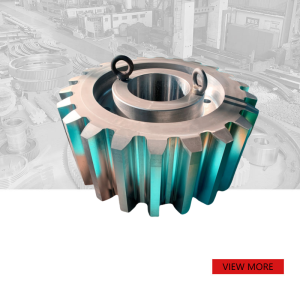

Forging high quality Large diameter Bevel gear

PRODUCT PARAMETERS

Description

Overview of Bevel Gear

Straight Bevel Gears are a type of gear used to transmit motion between intersecting shafts. They are characterized by their straight teeth, which are cut at an angle relative to the axis of rotation, forming a conical shape.

| Q | A | Q | A |

| Product name | bevel gear | Delivery time | 45-75Days |

| Material | Alloy steel | Defect Control | UT, MT |

| Process | Forging+CNC machining+HT | tooth profile | spiral bevel gear |

| outer diameter | According to the drawings | weight (kg) | 800 |

| Heat Treatment | Quenching & Tempering | Certificate | ISO9001 |

Application of Bevel Gear

The application of Straight Bevel Gear in the crusher is very critical. Straight Bevel Gear, the application of crusher is very critical, high quality straight bevel gear can provide accurate speed conversion and smooth power transmission.

Production process of Bevel Gear

Forging

The blank is heated to a plastic state and then die forged on a forging hammer or press to form the rough shape of the gear. Forging can improve the internal structure of materials and improve mechanical properties.

Rough Machining

The roughing of the spur gear shaft is an important step in the manufacturing process, which lays the foundation for the subsequent finishing. The purpose of roughing is mainly to remove most of the excess material, so that the workpiece is close to the final shape and size, while improving the internal stress distribution of the material.

Heat treatment

Quenching and tempering are usually included to obtain the desired balance of hardness and toughness, ensuring that the gear has sufficient strength and wear resistance.

Finishing

The finishing of the spur gear shaft is a key step that takes place after the roughing is completed, aiming to ensure that the gear shaft meets high precision and high quality standards. Finishing not only improves the dimensional accuracy, shape accuracy and surface finish of the parts, but also ensures the correct fit between the gear and the shaft and the smooth operation of the entire transmission system.

Precision turning or grinding of the outer diameter, inner hole and end face of the gear to ensure the accuracy of the assembly size.

Surface treatment

Galvanizing, chrome plating, blackening or other anti-corrosion treatments may be performed, as well as surface hardening treatments such as nitriding, carburizing, etc., to enhance the corrosion and wear resistance of the gear.

Package of Bevel Gear

Oiling or Coating: Applying a thin layer of rust-preventative oil or another protective coating can shield the surface from moisture and contaminants.

Packing: fumigation-free wooden case customized according to product size. If necessary, a steel frame will be welded to the outside of the wooden box to assist the operation of the forklift truck.

FAQs of Bevel Gear

1.What module of gear can you produce? –8-120

2.What is the accuracy grade you can achieve? –6-8

3.What kind of payment terms do you have? –T/T & L/C

4.Whether to provide samples? –No

REQUEST A QUOTE

RELATED PRODUCTS

Forging 17CrNiMo6 wear resistant surface carburizing gear

Forging AISI4140 non-standard large Helical gear for ball mill

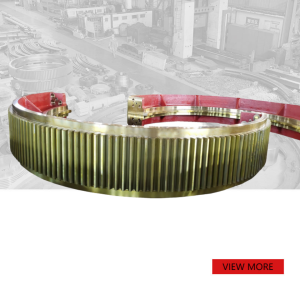

Non-standard customized rotary kiln casting gear ring

Forging cuatomized 42CrMo large module mining machinery Spur Gear

35CrMo Forging Mining large dimeter 12 Segment Arc Tooth