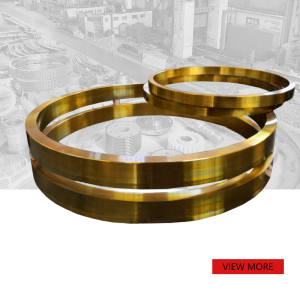

Non-standard alloy steel large diameter casting rotary kiln tyre

PRODUCT PARAMETERS

Description

Overview of Rotary Kiln Tyre

The wheel belt of casting rotary kiln is the key supporting part of rotary kiln, and the stable rotation of kiln body can be realized through its coordination with rolling ring. Wheels are usually made of cast steel with high strength and wear resistance to withstand high temperatures, heavy loads and friction.

| Q | A | Q | A |

| Product name | Kiln Tyre | Delivery time | 45-60 days |

| Material | Cast Iron | Defect Control | UT, MT |

| Process | Casting +CNC machining+HT | Color | Custom |

| outer diameter | According to the drawings | weight (kg) | 5980 |

| Heat Treatment | Quenching & Tempering | Certificate | ISO9001 |

Production process of Rotary Kiln Tyre

Casting

The process of casting a rotary kiln wheel blank first involves the preparation of a precise mold, usually using the sand casting method. Next, alloy materials suitable for high temperature and heavy load conditions are selected for smelting to ensure that the chemical composition meets the standards. The molten metal is then injected into the mold, and the pouring speed and temperature are controlled to ensure quality. After the casting is cooled and solidified in the mold, the mold is removed and the surface sandy residue is cleaned. Finally, a preliminary inspection of the blank is carried out to check the dimensional accuracy, surface quality and internal defects to ensure that it meets the design and use requirements.

Cast blank of Rotary Kiln Tyre(2)

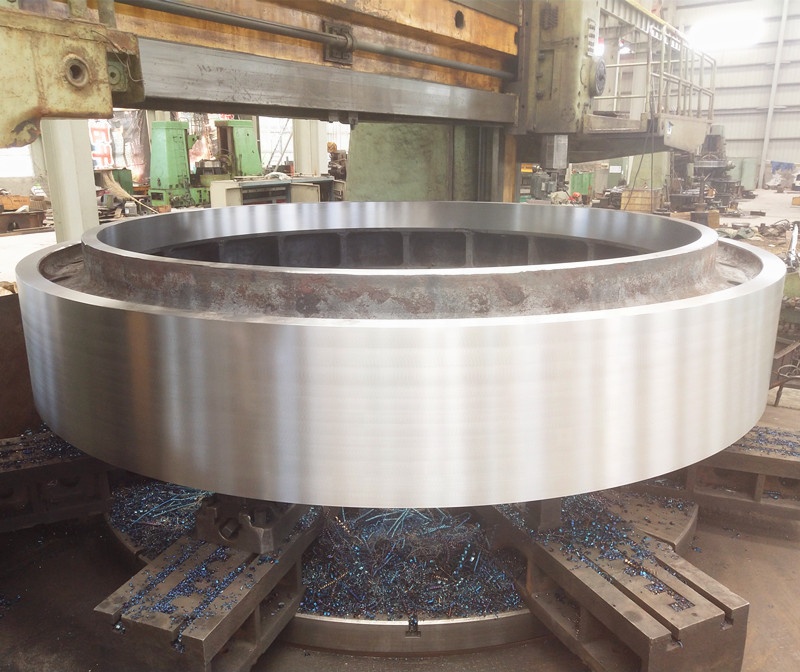

Rough Machining

Rotary kiln belt roughing includes: removal of excess material on the surface of the cast blank, preliminary turning, milling and surface processing to ensure that the overall dimensions are close to the final requirements and prepare for finishing.

Heat treatment

Heat treatment of rotary kiln wheels includes preheating, heating to quenching temperature, holding, quenching cooling, followed by high temperature tempering to optimize hardness, toughness and stress distribution and ensure stable performance.

Heat treatment of Rotary Kiln Tyre(3)

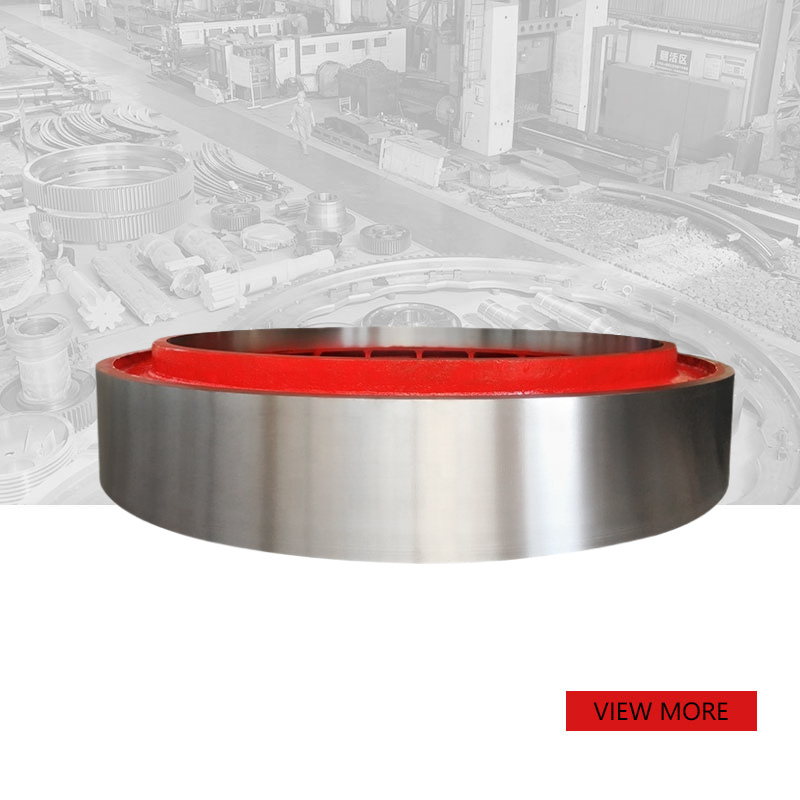

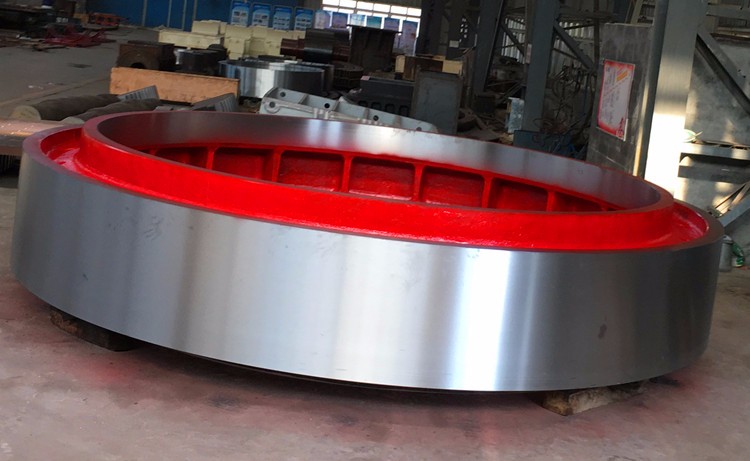

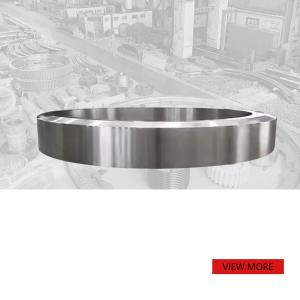

Finishing

The finishing process of casting rotary kiln wheel belt mainly includes: heat treatment of casting blanks to optimize material properties, then through turning, milling, grinding and other processes to ensure dimensional accuracy and surface finish, and finally flaw detection and quality inspection to ensure that the product meets the design requirements and use standards.

Finishing Machining of Rotary Kiln Tyre(4)

Package of Rotary Kiln Tyre

Oiling or Coating: Applying a thin layer of rust-preventative oil or another protective coating can shield the surface from moisture and contaminants.

Packing: fumigation-free wooden case customized according to product size. If necessary, a steel frame will be welded to the outside of the wooden box to assist the operation of the forklift truck.

Package of Rotary Kiln Tyre(5)

FAQs of Rotary Kiln Tyre

1.What is the accuracy grade you can achieve? –6-8

2.What kind of payment terms do you have? –T/T & L/C

3.Are you subject to third-party testing?-Yes

4. What’s your ship method?– By sea. By rail. By air.

REQUEST A QUOTE

RELATED PRODUCTS

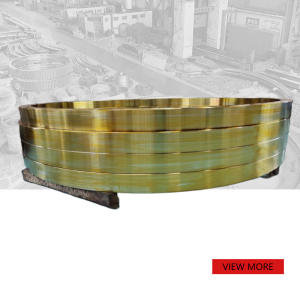

Custom large diameter rolling steel hot forging ring

42CrMo4 China Big Forging Steel Cement Rotary Kiln Large Support Roller Shaft

Custom Casting Rotary Kiln Tyre

Non-standard custom high quality 42CrMo forging ring

Customized 35# casting Two segment spur girth gear copper mine mill