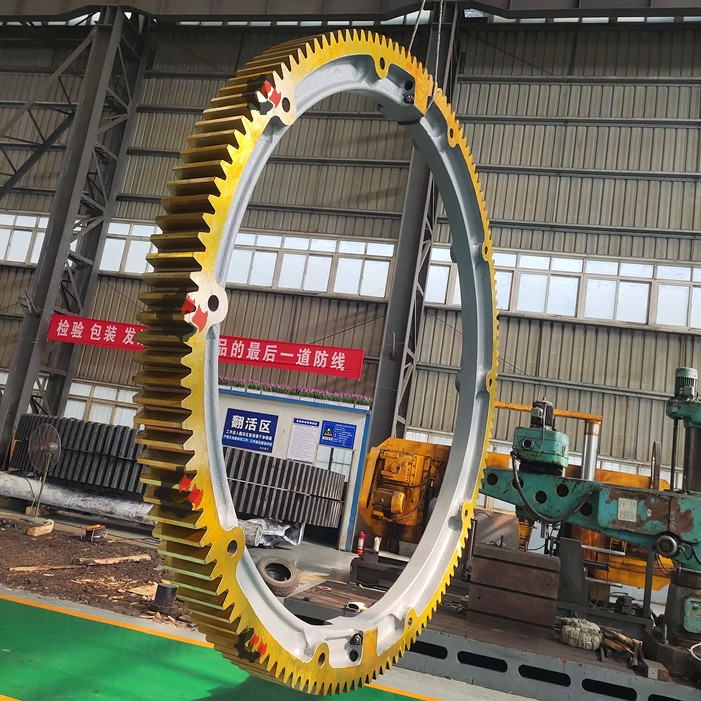

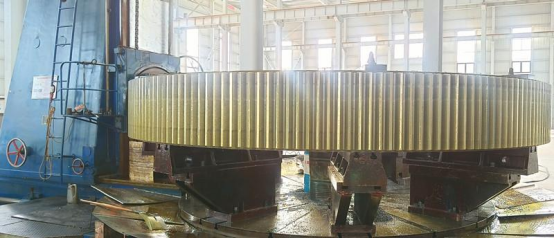

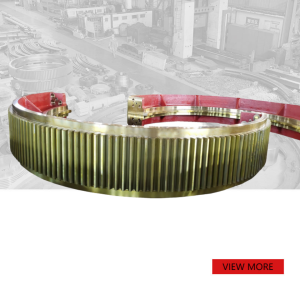

Customized casting ring gear for Ball mill

PRODUCT PARAMETERS

Description

一. ring gear Overview

The most common type is installed outside the cylinder. This type of large gear ring is usually installed outside the ball mill or rotary kiln to provide rotational drive. It needs to run for a long time and is a very important component in the transmission device. Therefore, the quality requirements for large gear rings are relatively high in actual production.

二. Application

These ring gear are suitable for mining, cement, chemical and other industries, and are used in ball mills, lime kilns, and dryer equipment.

Other large rotating bodies: Used in engineering loading machinery rotation, radio telescopes, salvage ships, lock opening and closing, ship capsizing machines and other equipment

三. Features

1. Simple cross-section.

2. High requirements for teeth.

3. Usually used for heavy loads.

四. Production process

- The blank process of the casting gear ring includes: designing the mold, melting the appropriate metal, pouring the molten metal into the preheating mold, cooling and solidifying the mold, initially cleaning the surface, and forming the casting blank with the basic shape of the gear ring.

2.First time of gear hobbing

3.Quenching and tempering

We have our own heat treatment workshop.

All of 6 sets of equipment are well-electric furnace and complete quenching medium(Oil,Salt water, Water, Sythetic quenching medium)

Through heat treatment, the hardness and strength of the product can be provided, and the internal organizational structure can be adjusted to obtain the best mechanical properties of the product.

4.Finish machining and final gear hobbing

5.Testing

6.Packing and delivery

fumigation-free wooden case customized according to product size. If necessary, a steel frame will be welded to the outside of the wooden box to assist the operation of the forklift truck.

FAQs of large ring gear

1.What module of gear can you produce? –8-120

2.What is the accuracy grade you can achieve? –6-8

3.What kind of payment terms do you have? –T/T & L/C

4.Are you subject to third-party testing?-Yes

5. What’s your ship method?– By sea. By rail. By air.

REQUEST A QUOTE

RELATED PRODUCTS

Customized forging high quality segment ring gear

forged steel pinion helical gear

Non-standard customized rotary kiln casting gear ring

Custom sugar mill pinion forging large gear

42CrMo forging cone crusher wear-resistant Straight bevel gear