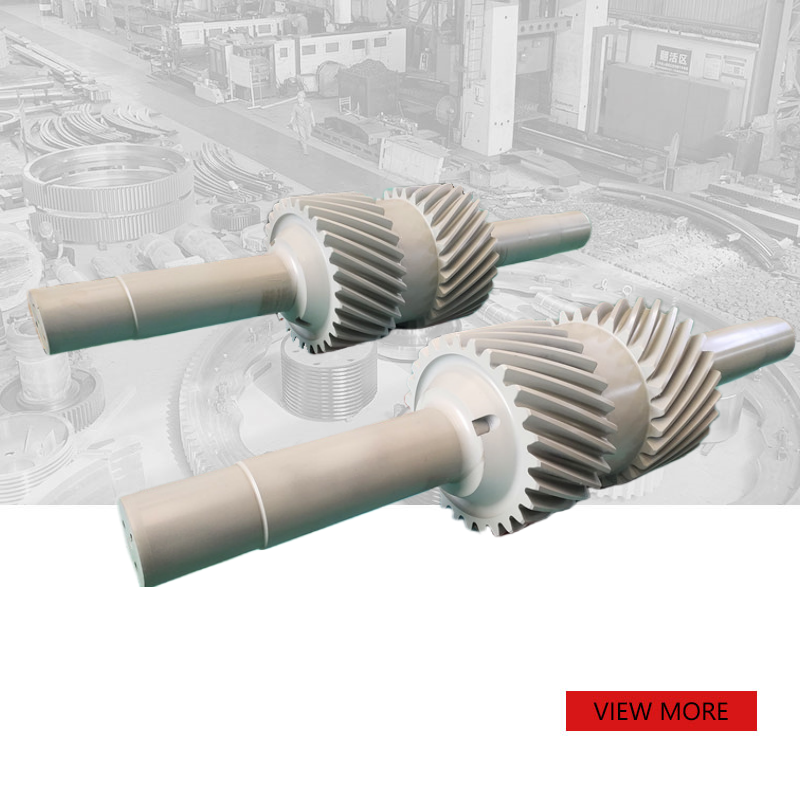

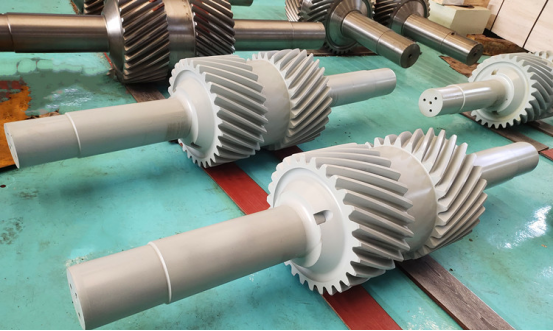

Customized forging steel herringbone gear shaft

PRODUCT PARAMETERS

Description

1. Overview of herringbone gear shaft

The herringbone gear shaft is a special mechanical transmission element, characterized by a “herringbone” shape of teeth, that is, the teeth on both sides are in opposite directions. This design combines the advantages of straight teeth and helical teeth, not only improving the load-bearing capacity, but also effectively reducing the operating noise. The design of adding back-off grooves during the customization process can facilitate the tool withdrawal during the processing process and ensure the processing accuracy and efficiency.

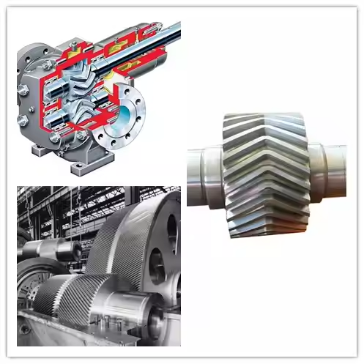

- Application of herringbone gear shaft

Herringbone gear shafts are widely used in heavy industry, such as large mechanical equipment in metallurgy, mining, cement and other industries. They are particularly suitable for occasions that require large torque transmission and require smooth operation, such as rolling mills, hoists, etc. In addition, they can also be seen in ship propulsion systems and wind power generation equipment because they can provide stable and reliable power transmission.

3. Features of herringbone gear shafts

Herringbone gear shafts have excellent mechanical properties and can withstand high radial and axial loads. Its symmetrical herringbone tooth design helps to disperse stress, reduce wear and extend service life. At the same time, the double-sided helical gear structure can balance the axial force, reduce vibration and noise levels, and achieve a quieter and smoother operating experience. The presence of the undercut further enhances the flexibility and quality control during manufacturing.

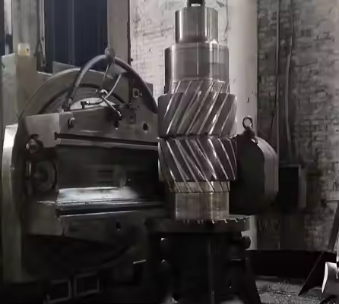

4. Production process

– Forging blanks

In the forging step, we design the best forging blanks to reduce the cost of raw materials, thereby saving money for customers.

– Rough machining

– UT or MT

Ultrasonic testing or magnetic particle testing after rough machining of forged and cast parts.

Ensure that all products are produced with high-quality raw materials.

– Finishing

– Packaging

In order to avoid rust and damage of finished products during transportation, we will be based on

The shape, size and purpose of the product.

5.FAQs of shaft

-How long is the delivery time? 45-80 days

-What are the packaging methods? According to customer requirements, plywood boxes are generally used.

-Do you accept third-party inspection? Yes