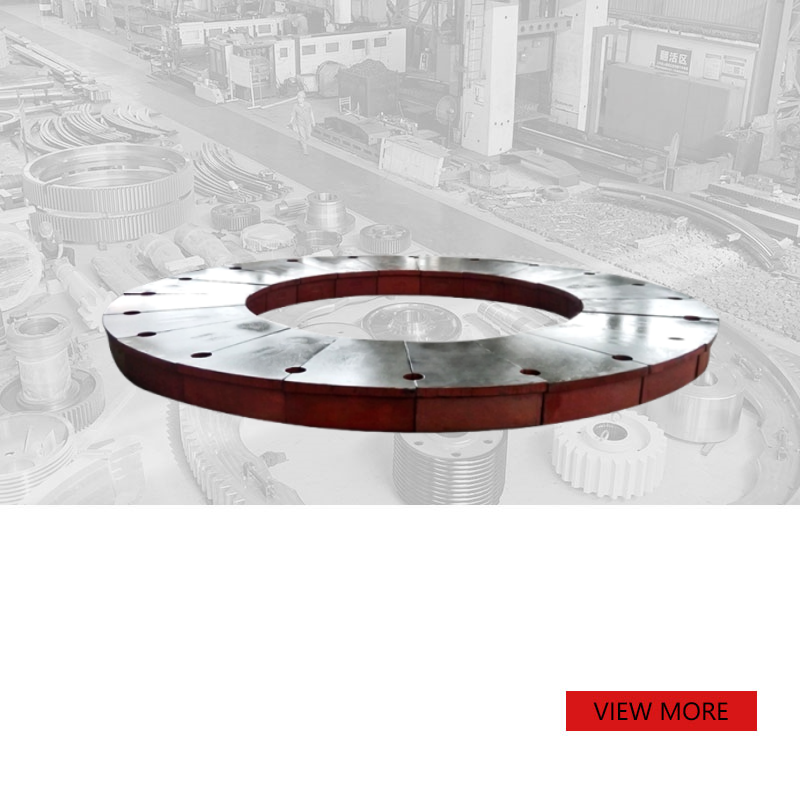

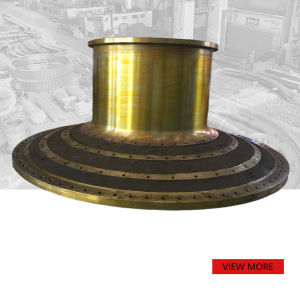

Alloy chromium wear-resistant lining for vertical ball mill

PRODUCT PARAMETERS

Description

1. Overview of rotary kiln ball mill lining

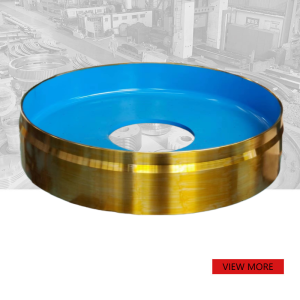

Alloy chromium wear-resistant lining for cement rotary kiln vertical ball mill is a key component used to protect the internal structure of the ball mill from direct wear of grinding materials and media. These liners not only help to extend the service life of the equipment, but also improve production efficiency by optimizing the grinding environment. Made of chromium materials with high alloy content, it ensures the excellent performance of the lining under high temperature, high pressure and strong wear conditions.

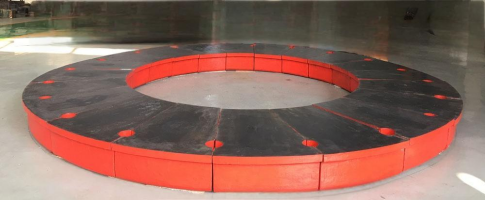

2. Classification and characteristics of rotary kiln ball mill lining

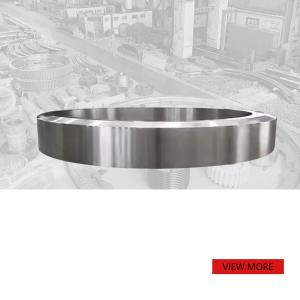

According to different working requirements, rotary kiln ball mill linings are designed into various types, such as smooth type, toothed type, stepped type, etc., each type has its own unique advantages to adapt to specific processing tasks. For example, toothed linings can enhance the impact crushing effect; while stepped linings are conducive to material stratification and improve grinding efficiency. All types of linings are made of high-quality alloy chromium materials with extremely high hardness and good wear resistance.

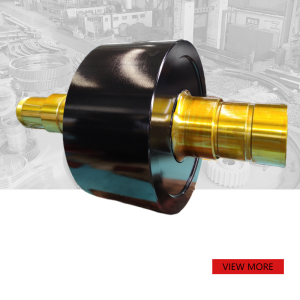

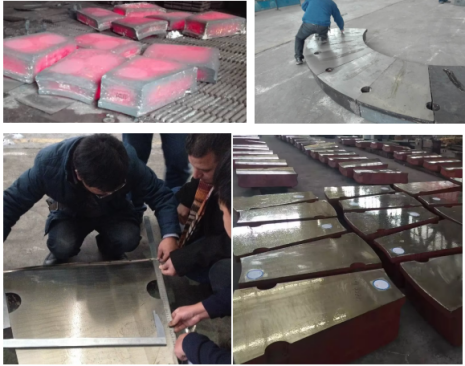

3. Installation method and function

When installing the liner, it is necessary to strictly follow the instructions provided by the manufacturer, including precise measurement, positioning, fixing and other steps. The main function of the liner is to reduce the friction loss between the inner wall of the mill and the grinding media, while promoting uniform distribution of materials to ensure an efficient grinding process. Correct installation can effectively reduce maintenance costs and ensure long-term stable operation of the equipment.

4. Selection and requirements of rotary kiln ball mill liner materials

Choosing the right liner material is crucial to ensuring the working efficiency of the ball mill. Commonly used liner materials include high chromium cast iron, nickel hard cast iron and other special alloys. Such materials must have excellent wear resistance, sufficient toughness and corrosion resistance to maintain optimal performance under harsh working conditions. In addition, in order to meet the needs of special applications, new materials with specific properties can also be customized and developed.

Parameter table

| Material | High chromium cast iron/nickel hard cast iron |

| Size | 100~2000mm according to customer demand |

| Hardness | HRC 60-68 |

| Wear resistance | High efficiency wear resistance |

5. Application scenarios, common problems and maintenance

This product is widely used in industries such as cement manufacturing, especially for coarse grinding operations that handle hard materials. Common usage problems are excessive wear and local damage, which can usually be prevented by regular inspection and timely replacement of damaged parts. In order to keep the lining in good condition, it is recommended to establish a standardized daily maintenance system, such as regularly cleaning surface dirt, checking fastening bolts, etc.

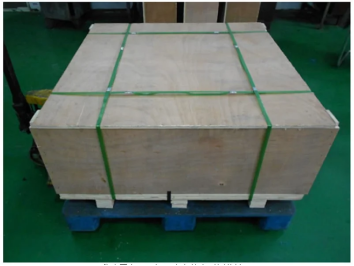

6. The packaging of rotary kiln lining materials is sustainable and recyclable, with little impact on the environment.

We have more than 15 years of export experience, and we strive to improve the packaging solutions and strive to adopt the most reasonable transportation methods and packaging solutions. The lining materials used are in line with environmental protection standards, have good sustainability and recyclability, and are committed to reducing the impact on the natural environment. Our products and services have won wide recognition and support from domestic and foreign customers.