Casting large diameter wear resistant pulley mining dragline

PRODUCT PARAMETERS

Description

一.Overview

Casting large diameter wear resistant pulley mining dragline

The pulley of mine dragline excavator, also known as a pulley or guide wheel, is a key component used to guide and support the wire rope. It is usually made of wear-resistant materials with high strength and corrosion resistance to cope with harsh working environments. The pulley is designed with smooth grooves to ensure proper alignment of the wire rope, reduce wear and prevent ungrooving. It is also characterized by its ability to withstand high loads, flexible rotation, and good self-lubrication performance, thus ensuring efficient and safe excavation operations.

二.Usage

The pulley we produce are mainly used in mining machinery

三.Production progress

1.Casting

The casting process is capable of producing complex shapes and is suitable for producing pulley with special design requirements. Different materials, such as cast iron or aluminum alloy, can be selected as needed to optimize weight and strength ratios. In addition, casting can achieve near-net molding, reduce the amount of subsequent processing, reduce costs and improve production efficiency, and the casting process helps to uniform the material organization, enhance the overall mechanical properties and durability of the pulley, ensuring stable operation under high load conditions.

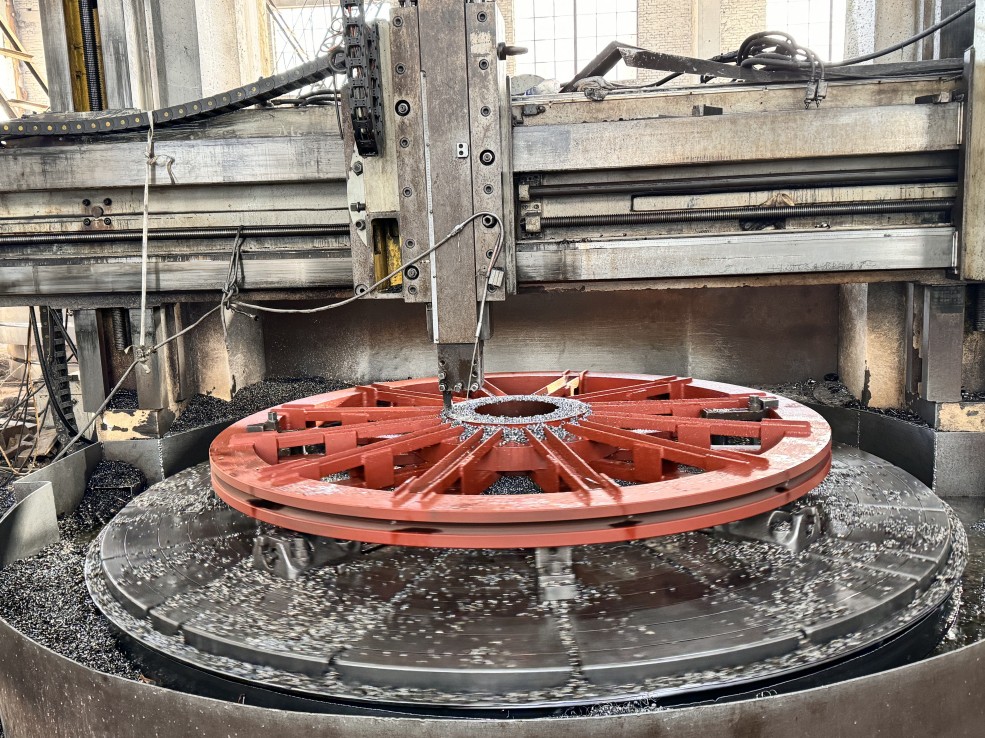

2.Rough machining

The significance of roughing the casting pulley is to remove excess material, preliminary molding, and correct the size and shape deviations generated during the casting process. This step lays the foundation for finishing and ensures the accuracy of subsequent processes, while at the same time being able to detect and treat potential defects such as pores or cracks to ensure the quality and performance of the final product.

3.Heat treatment

The heat treatment of the cast pulley can optimize the mechanical properties of the material, increase the surface hardness and wear resistance, while improving the internal stress distribution and improving the toughness and fatigue strength. This ensures the stable operation of the pulley under high load and complex working conditions, prolongs the service life, and ensures the reliability of the transmission system.

4.Finish machining

The finish machining after heat treatment can further improve the precision and surface quality of the cast pulley, ensuring dimensional accuracy and shape consistency. It can eliminate the fine deformation caused by heat treatment, optimize the smoothness of the matching surface, reduce operating noise and wear, and enhance the transmission efficiency, so as to ensure the high performance and long life of the belt pulley in practical applications.

5.Package

80% of our products are exported, so in general, we will develop packaging suitable for export according to customer requirements and combined with product characteristics

四.FAQ

1.Can you provide the mechanical performance report?-Yes

2.Can you accept the third party inspection?-Yes

3.What kind of payment terms do you have?-T/T & L/C

4.What currency do you generally accept?-USD/EUR/RMB

REQUEST A QUOTE

RELATED PRODUCTS

Mining Machinery Dragline Excavator Large Steel Casting Rope Wheel

Customized Large Diameter Non-standard Slewing Bearing for Heavy Excavator

Custom forging gear rack for Dragline excavator

Dragline excavator custom forging rail

Mining Large Steel Casting Sheave wheel Custom Rope sheave