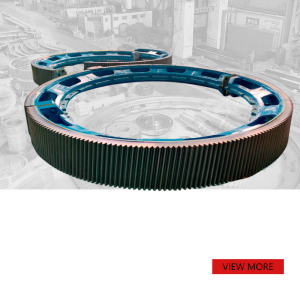

Casting ZG30# large diameter spur gear conveyor

PRODUCT PARAMETERS

Description

一.Overview

| Material | Carbon steel/Alloy steel |

| Tooth profile | Spur/Helical |

| Structure | Casting/Forging |

| Surface treatment | Surface hardening |

| Module | 8-120 |

二.Production process

1.Mold

Doing a good job of modeling the cast gear is crucial to ensure precise shaping and dimensional accuracy of the gear. High-quality models can reduce the amount of subsequent processing, reduce costs, and ensure the consistency of key parameters such as tooth profile and tooth spacing. In addition, it helps to increase production efficiency and ensure the mechanical properties and durability of the gear to meet the stringent application requirements.

2.Rough machining

Rough machining the casting gear blank can remove the excess material, correct the casting deviation and form the basic profile. This not only reduces the load of subsequent finishing, but also enables the detection and treatment of potential defects such as pores or cracks. Roughing lays the foundation for final precision and surface quality, ensuring the performance and durability of the gear.

3.Heat treatment

We have our own heat treatment furnace,6 sets well-type electric furnace,4 kinds of quenching medium. The temperature difference can be controlled within ±1℃. The product can obtain the best mechanical properties after heat treatment.

4.Finish machining

The gear hobbing process after heat treatment can accurately correct the tooth shape and tooth pitch to ensure high precision meshing performance. Gear hobbing improves tooth surface finish, reduces noise and vibration, and increases transmission efficiency. In addition, it can eliminate the small deformation caused by heat treatment, ensure the consistency and reliability of the gear size, and extend the service life.

5.Package

According to the requirements of customers, we apply anti-rust oil to the whole product for anti-rust treatment. In addition, we can also paint the products according to the needs of customers to prevent rust. And then it goes into a fumigation-free plywood box

三.Usage

Due to its ability to withstand high loads and complex working conditions, cast gears are mainly used in the following equipment:

a: Heavy machinery, such as mine diggers

b: Rotary kiln, mill

c: Lifting and conveying equipment

REQUEST A QUOTE

RELATED PRODUCTS

Customized casting ring gear for Ball mill

Customized main transmission forged steel large diameter spur gear

Customized 35# casting Two segment spur girth gear copper mine mill

Customized large modulus pinion for rotary kiln

Custom forging double helical gear