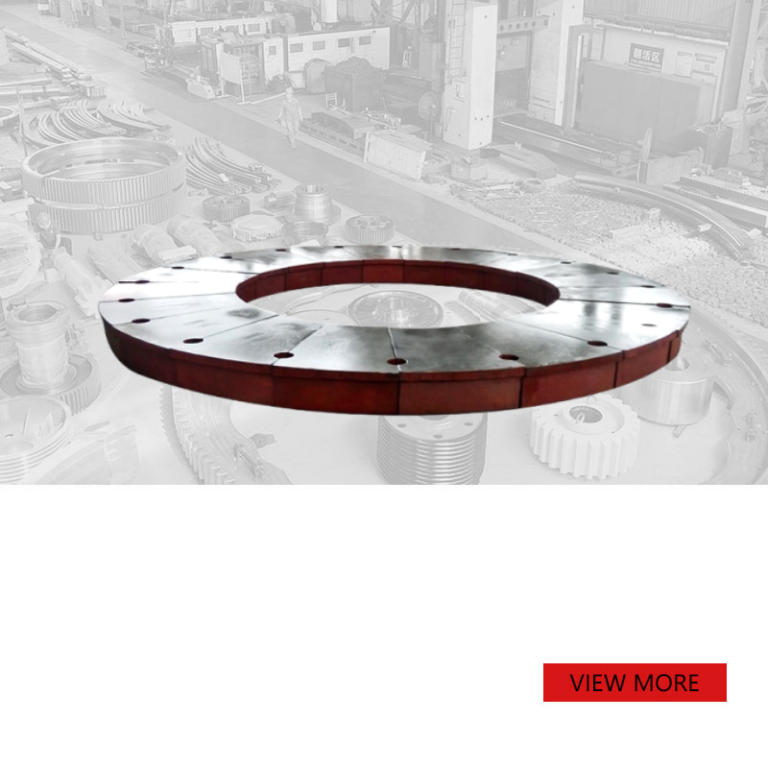

Customized 35# casting Two segment spur girth gear copper mine mill

PRODUCT PARAMETERS

Description

一.Overview

| Material | Caron steel |

| Gear profile | Spur gear/Helical gear |

| Segments | 2/4/6/8/12,etc |

| Accuracy | 8 |

| Structure | Casting/Forging |

二.Usage

Two segment girth gear refers to a complete gear ring is divided into two parts for manufacturing, and then it is spliced together to form a whole during installation. This design is mainly used in applications where it is not possible to manufacture the entire ring at one time due to size limitations, processing difficulties, or transportation difficulties. It is mainly used for:

a: Rotary kiln, ball mill

b: Mining machinery

c: Metallurgical industry

d: Lifting and lifting equipment

三.Production process:

1.Casting

Casting gear ring is a gear component manufactured by casting process. Casting can produce very complex geometric shapes, a wide range of product sizes, a variety of material choices, a variety of structural choices, and can also reduce blank weight.

2.Rough machining

The roughing of the girth gear can remove the excess metal material formed during the casting process, improve the dimensional accuracy of the product, remove surface defects, improve surface quality, find out if there are potential problems and reduce subsequent deformation

3.UT

The ultrasonic test of the girth gear can find whether there are defects inside the casting, such as cracks, pores, inclusions, improve the safety of the product and extend the service life of the product

4.Heat treatment

In general, the organizational structure and properties formed during the casting process may not meet the requirements of end use. Heat treatment can improve the hardness and strength of the product, enhance toughness and wear resistance, eliminate internal stress, improve processing performance and so on.

5.Finish machining

The gear hobbing of large girth gear is a very important gear manufacturing process, which can improve the precision of the tooth, improve the surface quality, enhance the bearing capacity, realize the requirements of complex tooth shape and the production efficiency of the gear hobbing process is high.

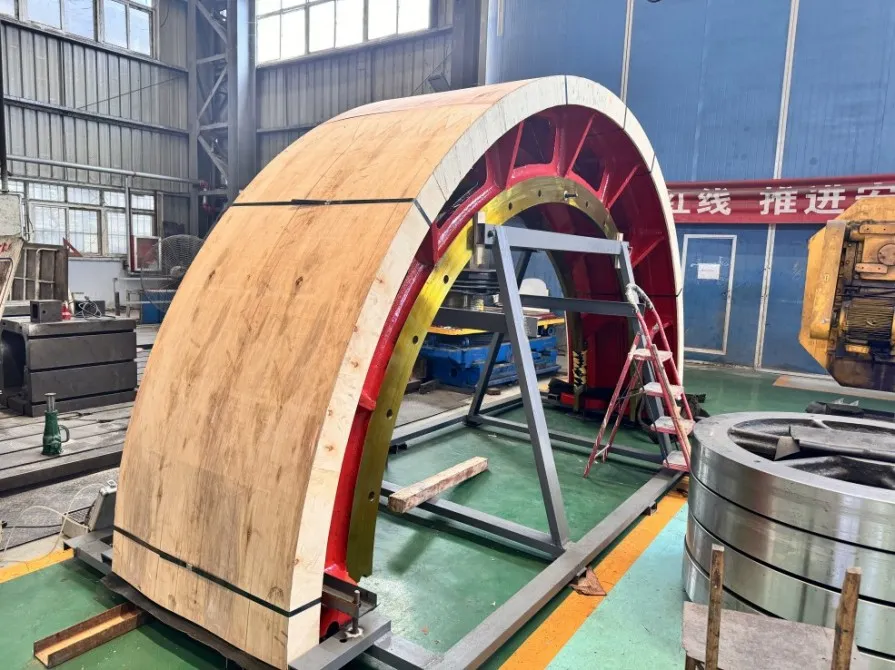

6.Inspection & Package

When the girth gear totally finished, our quality inspection team will test the finished product and issue a test report for customers.

And we are packed according to customer requirements and transported by railway container.

四.FAQ

1.Can you produce forged girth gear?–Yes

2.What is the largest diameter girth gear you can produce for the whole circle?-16m

3.What kind of payment terms do you have? -T/T & L/C

Contact us