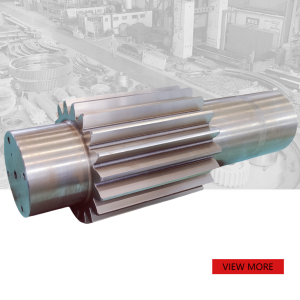

Non-standard alloy steel large diameter Fan Shaft

PRODUCT PARAMETERS

Description

Overview of Fan shaft

The fan shaft plays a key role in the wind power generation system, which is mainly used to connect the wind turbine and the generator, converting the wind energy into mechanical energy and then into electrical energy. It is designed with high strength and light weight in mind to withstand dynamic loads and reduce energy loss. The material is usually made of high-quality steel or alloy steel to ensure sufficient strength and durability.The fan shaft is divided into low speed spindle and high speed transmission shaft, corresponding to direct drive and gearbox driven generators respectively.

| Q | A | Q | A |

| Product name | Fan Shaft | Delivery time | 75-90Days |

| Material | Forged Iron | Defect Control | UT, MT |

| Process | Forging +CNC machining+HT | Color | Custom |

| outer diameter | According to the drawings | weight (kg) | 4980 |

| Heat Treatment | Quenching & Tempering | Certificate | ISO9001 |

Production process of Fan shaft

Forging

Material selection: Usually use high-quality carbon steel or alloy steel, these materials have good mechanical properties and weldability.

The steel is heated to the appropriate temperature (usually around 1200°C) to soften it for molding. Forging and pressing the heated steel by means of hydraulic press or hammering to form a preliminary shape. This step can eliminate internal defects, refine grain structure, and improve material strength.

Rough Machining

The basic shape and positioning datum are then machined using a lathe or milling machine to ensure the accuracy of subsequent finishing.

Heat treatment

Quenching and tempering: The purpose is to enhance the hardness and toughness of the material. The balance between hardness and toughness is adjusted by rapid cooling (quenching) after heating to a certain temperature, and then tempering treatment.

Finishing Machining

Further precision machining, including grinding, boring and other processes, to ensure that the dimensional accuracy and surface finish of each part meet the design requirements.

Surface treatment

Anti-rust treatment: such as painting, galvanized, etc., to protect the finished product from corrosion.

Package of Fan shaft

Cleaning treatment to remove surface impurities, anti-rust treatment to prevent oxidation, the selection of appropriate packaging materials such as wooden boxes or cartons, and add anti-shock cushion protection, and finally identify product information and handling precautions to ensure transportation safety.

FAQs of Fan shaft

1.What is the accuracy grade you can achieve? –6-8

2.What kind of payment terms do you have? –T/T & L/C

3.Are you subject to third-party testing?-Yes

4. What’s your ship method?– By sea. By rail. By air.

REQUEST A QUOTE

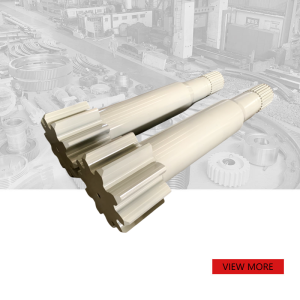

RELATED PRODUCTS

Custom forged 42CrMo large modulus gear shaft

Spur gear shaft forging high quality large diameter Ball Mill

34CrNiMo6 Alloy steel Helical gear shaft rotary kiln

Mining Forging 34XH3M large module spur gear shaft

35CrMo wear resistant Gear reducer large Helical Gear Shaft