4340 OEM Big Pinion Shaft Spur Toothed Forging Carbon Steel Spur Large Module Gear Shaft

PRODUCT PARAMETERS

Description

Overview of large Module Gear Shaft

Large modulus gear shafts are crucial in Oil equipment and are mainly used to drive all kinds of heavy machinery, such as Oil rig. By increasing the modulus, the strength and load bearing capacity of the gear are improved, and the working environment of the Oil equipment is adapted to high temperature and heavy load. This not only ensures the stable operation of the production line, but also improves production efficiency and safety, and plays an irreplaceable role in realizing automated and continuous production. The quality of large modulus gear shaft is directly related to the overall production capacity and product quality of Oil equipment.

| Q | A | Q | A |

| Product name | large Module Gear Shaft | Delivery time | 45-60 days |

| Material | Cast Iron | Defect Control | UT, MT |

| Process | Casting +CNC machining+HT | Color | Custom |

| Module | 100 | weight (kg) | 980 |

| Heat Treatment | Quenching & Tempering | Certificate | ISO9001 |

Production process of large Module Gear Shaft

Forging

The blank of forging a large modulus gear shaft (modulus 100) first needs to choose the appropriate raw material according to the design size. High quality alloy steel is usually used to ensure that the material has good mechanical properties. Forging process After the material is heated to the appropriate temperature in the heating furnace, the forging hammer or press is used for forming. This step aims to refine the grain structure of the material through plastic deformation, eliminate internal defects, and improve the strength and toughness of the part.

Rough Machining

The roughing stage is mainly to remove excess material to form the basic shape of the gear shaft. Using CNC lathe or planer and other equipment for preliminary processing of blanks. The key is to ensure that the outer diameter, length and rough dimensions of the end face of the gear shaft are accurate. Although the accuracy requirements are not high, sufficient margin must be left for subsequent finishing. This step lays the foundation for the geometry of the final product.

Finishing

Finishing is the key step to achieve high precision, including gear profile grinding, precision turning of gear journal and so on. The use of high-precision machine tools and special tools to ensure that the dimensions of each part meet the strict design requirements. Especially for large gear shafts with a modulus of 100, the smoothness and smoothness of the tooth surface are crucial. By fine-adjusting the machining parameters, the working efficiency and service life of the gear shaft can be effectively improved.

Heat treatment

The heat treatment process is used to enhance the hardness and wear resistance of the gear shaft. The general process includes quenching and tempering. First, the gear shaft is heated above the critical temperature for a period of time, and then quickly cooled to harden the surface. Next, tempering is performed at below critical temperatures to relieve internal stress and stabilize the structure. After proper heat treatment, the comprehensive mechanical properties of the material can be significantly improved.

Package

Cleaning treatment to remove surface impurities, anti-rust treatment to prevent oxidation, the selection of appropriate packaging materials such as wooden boxes or cartons, and add anti-shock cushion protection, and finally identify product information and handling precautions to ensure transportation safety.

FAQs of large Module Gear Shaft

1.What is the accuracy grade you can achieve? –6-8

2.What kind of payment terms do you have? –T/T & L/C

3.Are you subject to third-party testing?-Yes

4. What’s your ship method?– By sea. By rail. By air.

REQUEST A QUOTE

RELATED PRODUCTS

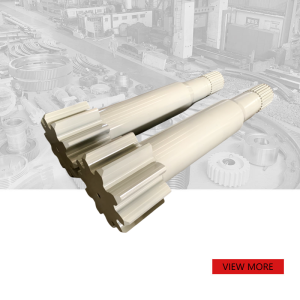

Mining high quality forging Helical gear shaft

Mining Forging 34XH3M large module spur gear shaft

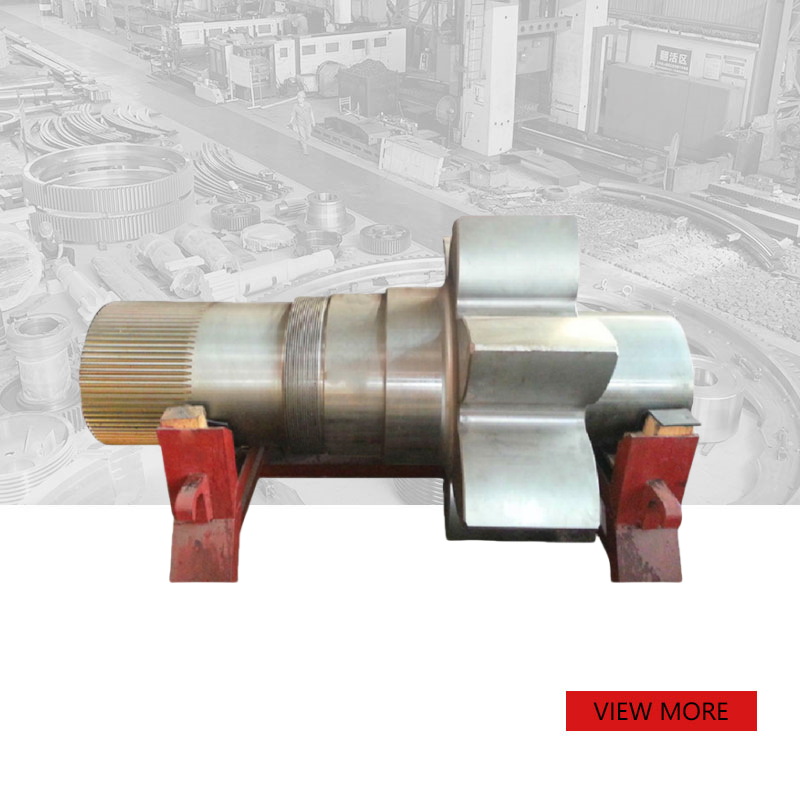

Spur gear shaft forging high quality large diameter for Ball Mill

Custom eccentric shaft with bearing seat

Customized Large Forging shaft for dragline/Walking excavator