Spur gear shaft forging high quality large diameter surface quenched

PRODUCT PARAMETERS

Description

Overview of Spur Gear Shaft

The surface hardened spur gear shaft is widely used in mining machinery to withstand high strength and harsh working environment by improving the hardness and wear resistance of the tooth surface. This treatment method can enhance the fatigue resistance and service life of the parts on the basis of maintaining the toughness of the core. In mining machinery such as crushers, conveyors and other equipment, the use of surface quenched spur gear shaft can effectively reduce the maintenance frequency and cost to ensure the stable operation of equipment. In addition, it improves mechanical efficiency and reduces energy consumption.

Production process of Spur Gear Shaft

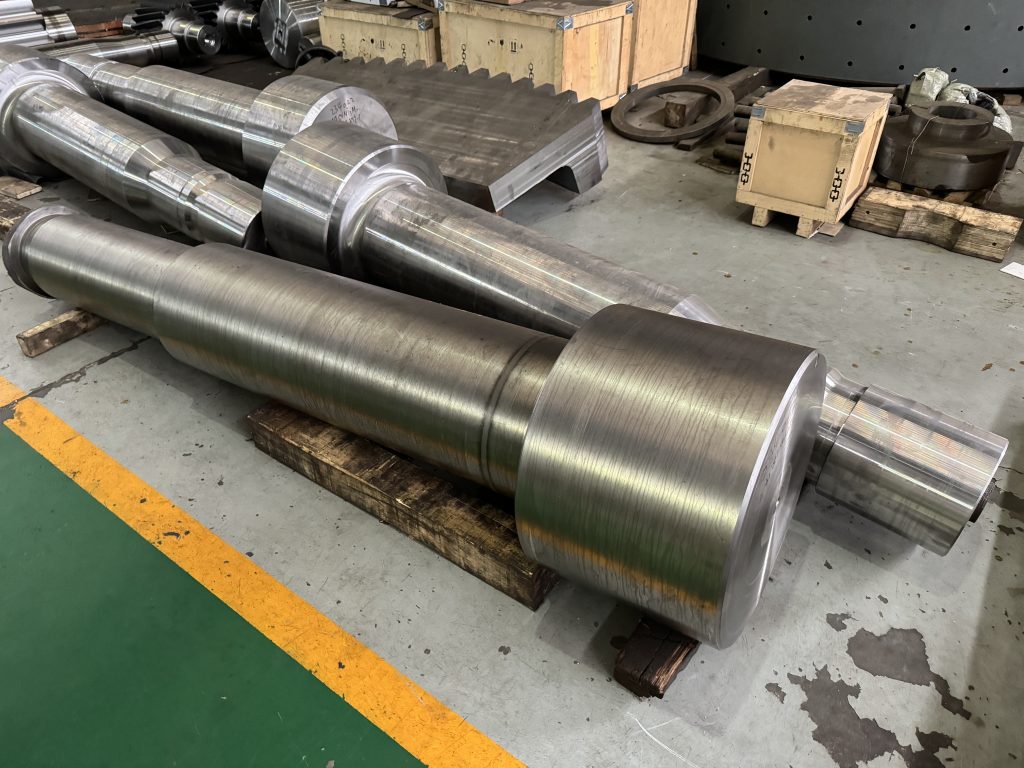

Forged blank

Blank forging is the initial step in the manufacture of spur gear shafts by heating the metal to the appropriate temperature and forging it with a die. This process increases the density and strength of the material and reduces internal defects. When forging, it is necessary to strictly control the heating temperature and forging strength to ensure that the material properties meet the requirements of subsequent processing. It is very important to choose the proper forging process parameters to improve the final quality of the product

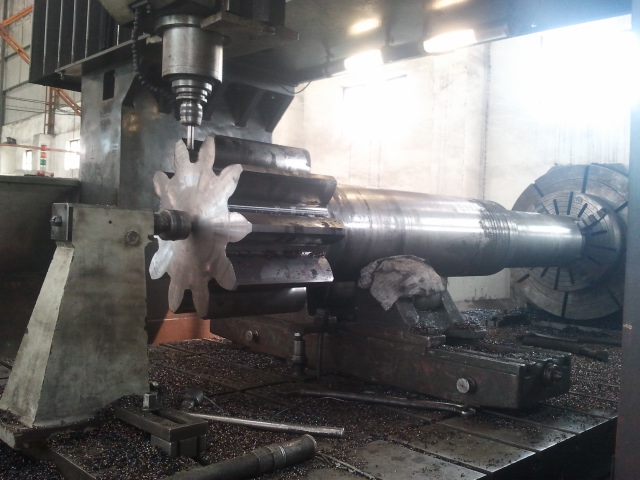

Roughing

The roughing stage is mainly for the preliminary forming treatment of the blank after forging, including turning, drilling and other operations, in order to remove excess material and form a rough outline. This step needs to consider the selection of tools and cutting parameters to ensure efficient material removal while avoiding workpiece deformation. Roughing provides the basic form for subsequent finishing, and its accuracy requirements are relatively low but the consistency of dimensions must be ensured.

Finishing

In the finishing process, high-precision machine tools are used for detailed machining of parts, such as grinding, boring, etc., in order to achieve the exact size and surface finish specified in the design. The process requires strict control of processing environmental conditions, such as temperature, humidity, and the use of high-precision measuring tools to detect product quality. Finishing directly determines the working performance and service life of the gear shaft, so it is necessary to ensure the precise execution of each step.

Heat treatment

Heat treatment is an important step to optimize the structure of spur gear shaft, which usually includes annealing, normalizing or tempering. Mechanical properties such as hardness, wear resistance and toughness can be improved by controlling the heating, holding and cooling rates to change the internal structure of the material. Reasonable heat treatment process can significantly improve the comprehensive mechanical properties of parts, prepare for subsequent surface quenching, and ensure that the gear shaft has good stability and durability in the working state.

Surface treatment

Surface quenching is a process of strengthening the key parts of the spur gear shaft (such as the tooth surface), mainly using induction heating or flame heating, so that the surface layer quickly reaches the quenching temperature and cools quickly. This step aims to increase the surface hardness of the part without affecting the balance of its core toughness, enhancing wear and fatigue resistance. The quality of surface quenching directly affects the service life and service efficiency of the gear shaft, so it is necessary to precisely control the heating speed, quenching depth and uniformity.

Package of Spur Gear

Oiling or Coating: Applying a thin layer of rust-preventative oil or another protective coating can shield the surface from moisture and contaminants.

Packing: fumigation-free wooden case customized according to product size. If necessary, a steel frame will be welded to the outside of the wooden box to assist the operation of the forklift truck.

FAQs of Spur Gear shaft

1.What module of gear can you produce? –8-120

2.What is the accuracy grade you can achieve? –6-8

3.What kind of payment terms do you have? –T/T & L/C

4.Whether to provide samples? –No

REQUEST A QUOTE

RELATED PRODUCTS

35CrMo wear resistant Gear reducer large Helical Gear Shaft

Mining custom casting large helical gear shaft assembly

Custom mining forging long helical gear shaft

Custom High Quality 42CrMo Forged Steel Pinion Shaft

4340 OEM Big Pinion Shaft Spur Toothed Forging Carbon Steel Spur Large Module Gear Shaft