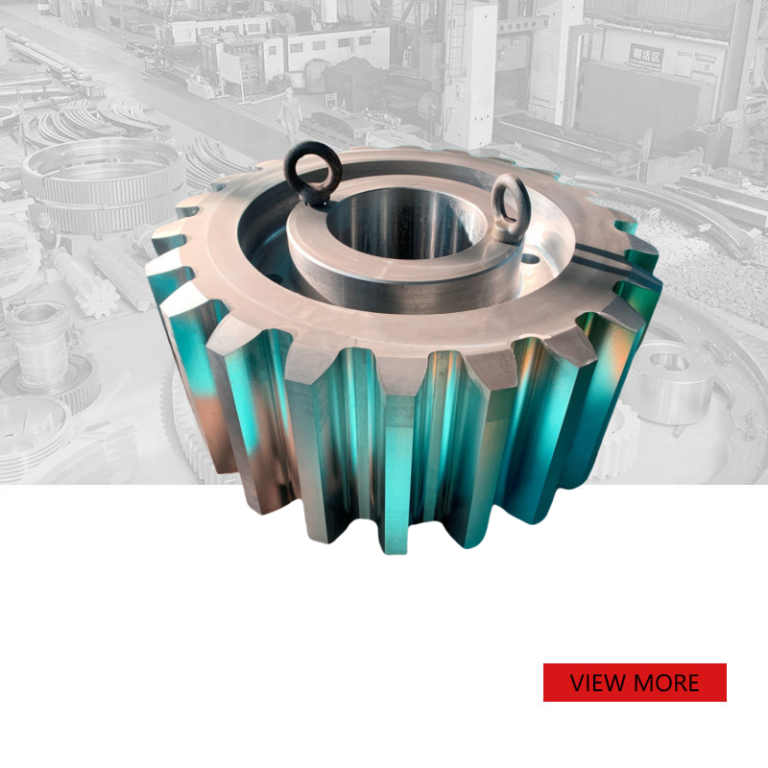

Customized main transmission forged steel large diameter spur gear

PRODUCT PARAMETERS

Description

1. Overview

We can produce large forged, cast and welded gears according to customer drawings. According to working conditions and customer requirements, we can also perform gear grinding, surface hardening, cementation quenching, nitriding quenching, etc.

2. Production process

-Forging

-Heat treatment

Customized large diameter spur gear-quenching and tempering If the gear module is large (above M25), the first hobbing is performed before heat treatment. According to this way, the hardness depth of the gear teeth will be deeper after QT, which can improve the mechanical properties of the gear teeth and can extend the service life of the gear.

-Gear processing

2-3 times of precision hobbing to ensure its gear accuracy and surface roughness. Only in this way can the spur gear work well with large gear rings or gear shafts.

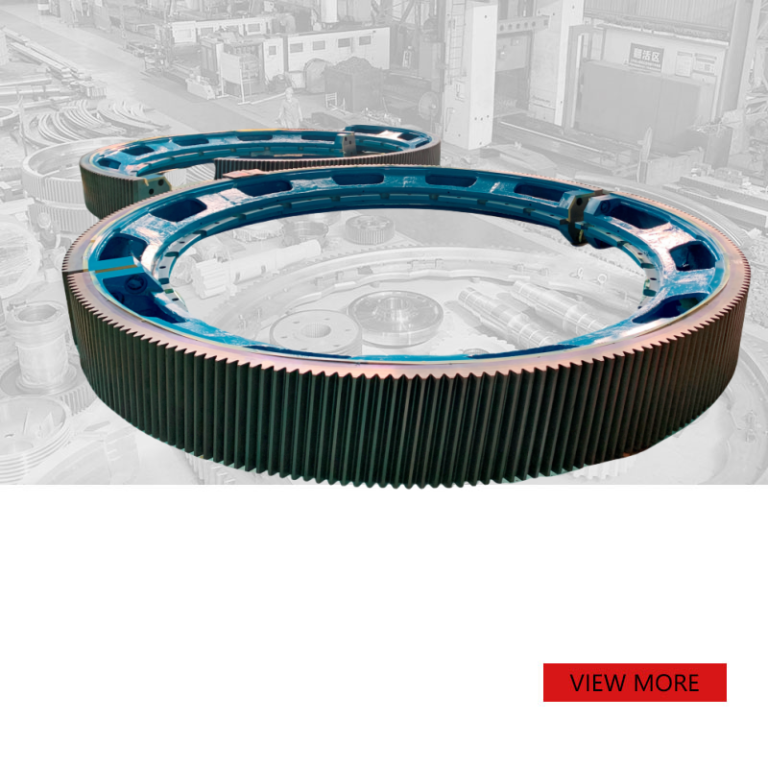

Complete hobbing of large diameter ring belt gears

The maximum accuracy level is 8 and the grinding accuracy level is 6.

-Inspection

After the gear is completed, we will provide you with a report on raw materials, hardness, and size information.

-Packaging

The choice of our packaging method is based on the characteristics of the product and the requirements of the customer.

- We can manufacture different types of gears according to drawings

| Material | Carbon Steel, Alloy Steel |

| Standard | ASTM DIN, EN GOST JIS, etc. |

| Structure | Forging, Casting, and Welding |

| Gear Module | 8-120 |

| Gear Grinding | Maximum Module 24 |

| Gear Diameter | Maximum 13,000 mm |

| Helical Gear Diameter | Max. 2,200 mm |

| Gear Shaft Length | Maximum 5,000 mm |

| Original Equipment Manufacturer Service | According to Customer Drawings |

| Subdivision Equipment Provided | According to Customer Requirements |

| Heat Treatment | Q&T Case Hardening |

4. Application

Our custom large diameter spur gears are mainly used in large cement plant equipment. Such as rotary kiln, ball mill, dryer, etc. We can also produce other large forged or cast ring gears for steel plants, dragline excavators. It can be a complete ring gear or half-segment gear, four segments, eight segments.

5.Why Choose Us

–OEM Mechanical Parts Supplier

More than 30 years of experience in manufacturing OEM mechanical parts and non-standard mechanical parts according to engineers’ drawings.

–Technical Support for Materials

Provide technical support for new materials and new manufacturing processes according to customers’ working conditions to improve the service life of mechanical parts.

Contact us