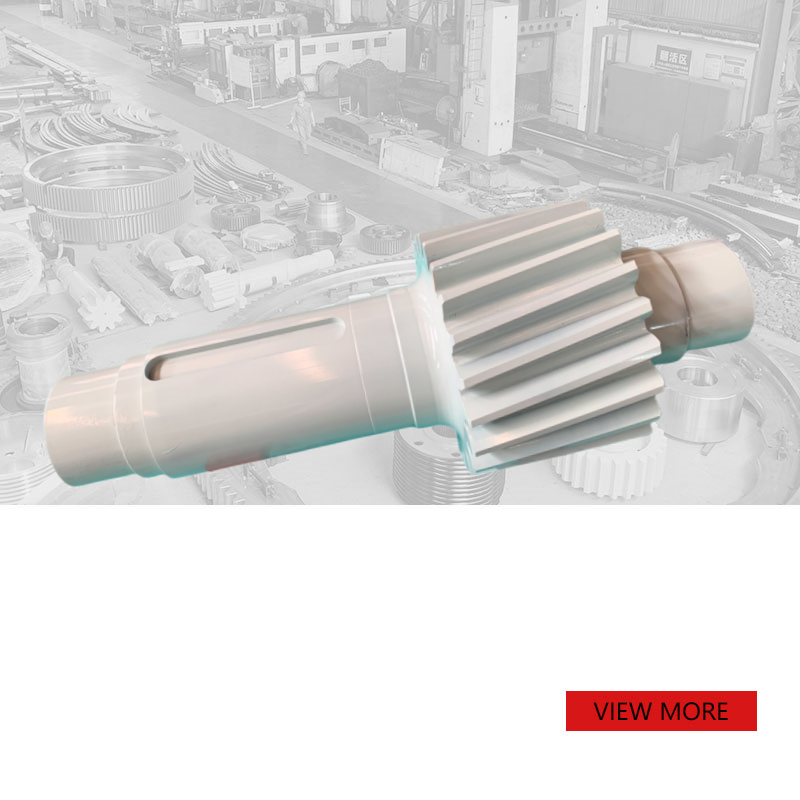

Custom High Quality 42CrMo Forged Steel Pinion Shaft

PRODUCT PARAMETERS

Description

1. Overview of pinion shaft

The custom forged 42CrMo large modulus pinion shaft is a high-strength and durable mechanical transmission component forged from high-quality alloy steel 42CrMo. This material is widely selected for its good mechanical properties and heat treatment characteristics. After precision forging, it can ensure that the pinion shaft has excellent mechanical strength, toughness and wear resistance, and is suitable for applications with high loads and impacts. Its large modulus design improves transmission efficiency while ensuring stable operation in harsh working environments.

2.pinion shaft application

Our large module pinion shaft is mainly used as transmission gear parts in dragline excavators, mills, cement rotary kilns, dryers and other industries.

3. pinion shaft production process

-Forging

We can produce pinion shaft blanks according to customer needs.

-pinion shaft roughing

Roughing can cut off most of the remaining materials in a short time, provide positioning accuracy benchmarks for semi-finishing and finishing, and detect blank defects in time.

-pinion shaft heat treatment

We strictly control the parameters of each product to ensure accuracy, QT can adjust the performance and materials to a large extent, and its strength, plasticity and toughness are all good.

-pinion shaft Finishing

Through finishing, we can better control the accuracy and surface roughness of the product.

-pinion shaft Packaging

In order to avoid rust and damage of finished products during transportation, we will be based on

The shape, size and purpose of the product.

5.FAQs of shaft

-How long is the delivery time? 45-80 days

-What are the packaging methods? According to customer requirements, plywood boxes are generally used.

-Do you accept third-party inspection? Yes

REQUEST A QUOTE

RELATED PRODUCTS

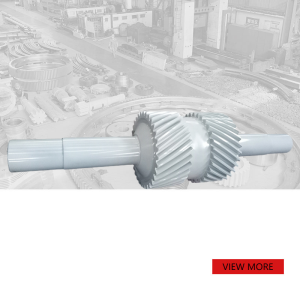

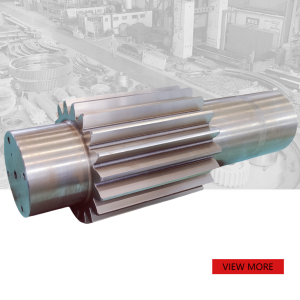

34CrNiMo6 Alloy steel Helical gear shaft rotary kiln

Custom Forged 42CrMo Non-standard Gear Shaft

Non-standard alloy steel large Double helical gear shaft with cutting groove

Customized non-standard Large module gear shaft transimission parts

34CrNiMo6Custom Reducer Herringbone Gear Shaft with tool return groove