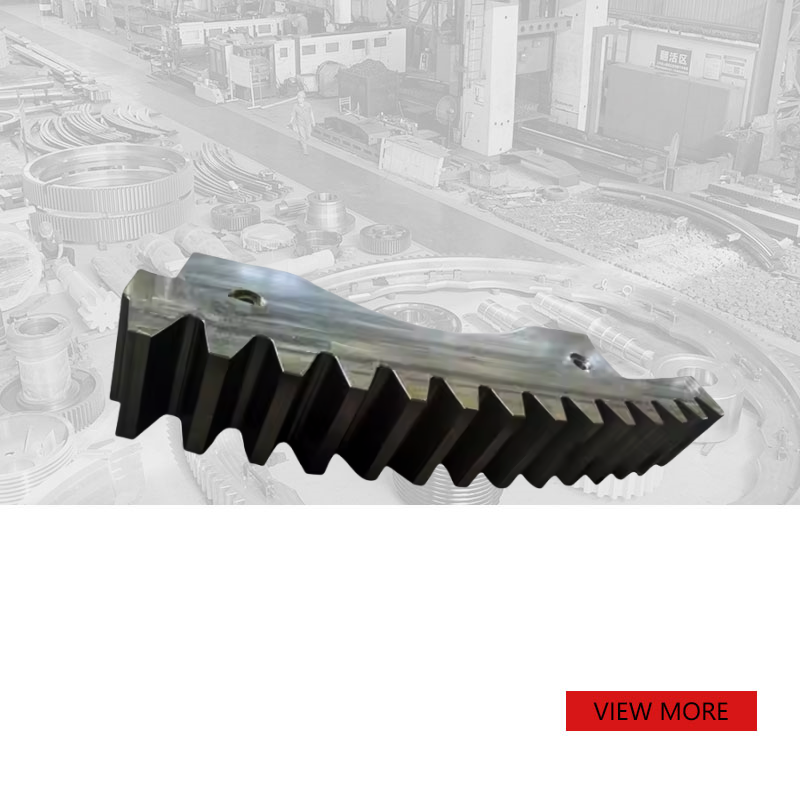

Customized forging high quality segment ring gear

PRODUCT PARAMETERS

Description

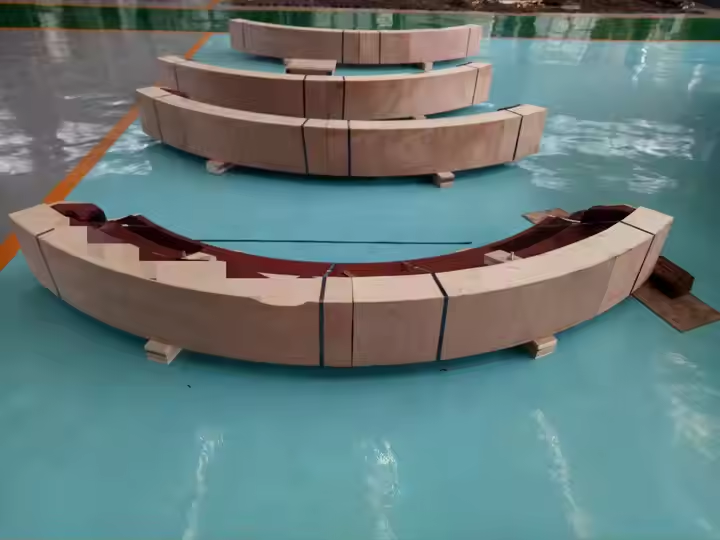

We can produce half gears, four-segment ring gear, eight-segment ring gear, twelve-segment ring gear; we can also produce cast and forged large module gears,large gear shaft.

- Product Description

Customization: According to customer drawings.

According to working conditions and customer requirements.

Parameter Table

| Material: | Carbon steel, alloy steel |

| Gear module: | 8-200 |

| Structure: | Forging |

| Gear length: | Maximum 10,000 mm |

| Standard: | ASTM DIN, EN GOST JIS, etc. |

| service: | Based on customer drawings |

| Heat treatment: | Q&A |

2. Production process

If the module of the gear or rack is large (above M20), the first CNC milling is performed before heat treatment. According to this way, the hardness depth of the gear teeth will be deeper after QT, thereby improving the mechanical properties of the gear teeth and extending the service life of the ring gear.

-UT test to ensure the quality of raw materials

After rough machining, we perform UT or MT test to ensure that there are no internal defects in the forged or cast blanks.

-Quenching and tempering

Before heat treatment, we perform the first gear cnc milling to ensure the overall hardness of the large module ring gear. In this way, its mechanical properties will be perfect.

– Processing large modulus forged ring gear

– Inspection

Test customized large ring gear size

– Packaging

In order to avoid rust and damage of large diameter segment ring gear during transportation, we will design suitable packaging according to the shape, size and purpose of the product.

3. Advantages of our heat treatment:

– Professional, specific furnace, single-minded- Vertical pit furnace, keep temperature uniform when heating, +/-1 ℃-

Small deformation, less oxide layer, reduce material cost

– Different materials can be cooled at the best speed

– Large capacity, complete various quenching media: oil, water, brine, water-based mixture.

4.Why choose us?

— OEM machinery parts supplier

More than 30 years of experience in manufacturing OEM machinery parts and non-standard machinery parts according to engineers’ drawings.

– Technical support for materials

Provide technical support for new materials and new manufacturing processes according to customers’ working conditions to improve the service life of machinery parts.

REQUEST A QUOTE

RELATED PRODUCTS

Customized large modulus pinion for rotary kiln

Non-standard alloy steel large diameter casting Casting gear

Forging AISI4140 non-standard large Helical gear for ball mill

Large Casting Iron two-segment Ring Gear Rotary Kiln

Casting ZG30# large diameter spur gear conveyor