Forging 17CrNiMo6 wear resistant surface carburizing gear

PRODUCT PARAMETERS

Description

一. Overview

By carburizing the surface of the gear, the surface hardness and wear resistance are improved, while maintaining the toughness and strength of the core. This treatment allows the gear to withstand wear, pitting and gluing at high loads and high speeds, extending its service life. Carburized gears are widely used in automotive, aviation and heavy machinery to provide reliable transmission performance under demanding working conditions, ensuring efficient operation and stability of mechanical systems. In addition, it reduces the frequency and cost of maintenance.

| Material | Carbon steel, Alloy steel |

| Module | 8-120 |

| Surface treatment | Surface carburizing, surface hardening |

| Tooth profile | Spur/Helical/Spiral |

| Accuracy | 6-8 |

| Pressure angle | 20° 25° |

二.Features

1. High surface hardness

2. Good fatigue resistance

3. Core toughness is good

4. High dimensional accuracy

三.Production process

1.Blank

Gear blanks are selected as forgings in large mining equipment spare parts, mainly because forgings can provide more uniform microstructure and higher mechanical properties, such as strength, toughness and wear resistance. The forging process refines metal grains and eliminates internal defects, thus ensuring better reliability and longer service life in high-load operating environments.

2.Rough machining

The roughing of the forging gear in the spare parts of large mining equipment can remove excess material, achieve close to the design size and shape, and reduce the workload and cost of subsequent finishing. At the same time, the internal defects can be found and eliminated during the roughing process, to ensure the quality and reliability of the parts, and to lay a good foundation for the subsequent heat treatment and finishing processes. In addition, it helps release internal stress and reduces the risk of deformation.

3.Heat treatment

The main purpose of heat treatment of gears is to optimize their mechanical properties. Heat treatment can enhance the hardness and wear resistance of the gear, while ensuring that the heart has enough toughness, improve the resistance to fatigue and impact. In addition, it helps to eliminate internal stress and reduce the risk of deformation and cracking during use, thereby extending the service life of gears and ensuring stable and efficient operation of mine equipment.

4.Semi-finish machining + Surface carburizing

The main purpose of carburizing the gear surface is to improve the hardness and wear resistance of the gear surface, while maintaining the toughness and strength of the heart. Carburizing can enhance the wear resistance of the gear, reduce surface fatigue damage such as pitting and wear, and thus extend the service life. In addition, this treatment can improve the anti-bite performance of the gear, reduce the risk of failure under high load operating conditions, and ensure long-term stable operation of the equipment.

5.Finish machining

After carburizing the surface, the forged gear is processed in order to achieve the final dimensional accuracy and surface finish requirements and ensure the assembly quality. This process can also remove defects that may occur during carburizing, such as oxide layer or uneven hardened layer, so as to further improve the performance and service life of the gear and ensure the stable operation of the mining equipment. In addition, finishing helps to achieve the required geometry and tolerance standards for the design.

6.Grinding

The gear grinding treatment is designed to improve the precision and surface finish of the gear, reduce noise and vibration, and ensure smooth transmission. Gear grinding corrects the deformation after heat treatment, improves contact accuracy, meets the exact tolerances required by the design, extends the service life, and reduces the energy loss during operation, thereby enhancing the performance and reliability of the entire equipment.

7.Package

Selecting the right gear packaging can prevent damage during transportation and storage, such as moisture, rust and collision prevention. Good packaging also makes it easy to handle and identify, ensuring that the gear reaches its destination safely and without damage, maintaining its performance and extending its service life.

四.FAQ

1.Can you produce the casting gear?–Yes

2.May i know can you do the surface nitriding? –Yes

3.May i know what test reports you can provide? –Chemical composition report, dimensions report, mechanical properties report, UT report,MT report,etc.

4.Do you accept the L/C? –Yes

REQUEST A QUOTE

RELATED PRODUCTS

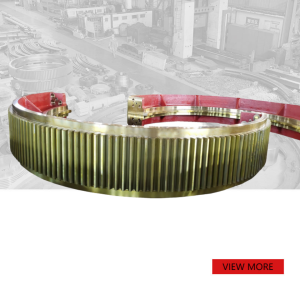

Non-standard customized rotary kiln casting gear ring

Casting ZG30# large diameter spur gear conveyor

Mining machinery bronze & alloy steel Worm & Worm gear

35CrMo Forging Mining large dimeter 12 Segment Arc Tooth

Customized wear-resistant 42CrMo forging spur gear