Spur gear shaft forging high quality large diameter for Ball Mill

PRODUCT PARAMETERS

Description

Overview of Spur Gear Shaft

In mining machinery, spur gear shaft, as a core transmission component, undertakes the key task of transmitting high torque and heavy load to ensure the stable operation of large equipment such as excavators and crushers. Its high strength and wear resistance design ADAPTS to harsh working environments, reducing maintenance requirements and extending service life. The precision-manufactured spur gear shaft can not only improve the overall efficiency of mechanical equipment, but also enhance the safety and reliability of operation, which is an important guarantee for the continuous and efficient operation of mines.

Production process of Spur Gear Shaft

Forged blank

The production of spur gear shafts begins with a forged blank by heating the metal to a plastic state and applying pressure to form a preliminary shape. This process requires strict control of temperature and deformation to ensure uniform internal organization and reduce defects. The high quality forged blank lays a solid foundation for the subsequent processing and directly affects the final performance of the spur gear shaft.

Roughing

In the roughing stage, the spur gear shaft is removed by turning, drilling and other processes to form the basic outline. This step is designed to efficiently approach the final dimensions while maintaining sufficient margin for subsequent finishing. Precise roughing ensures the geometric accuracy of the spur gear shaft and prepares it for subsequent processes.

Finishing

The finishing of spur gear shaft involves high-precision operations such as grinding and honing, in order to achieve the dimensional accuracy and surface finish required by the design. This stage requires strict tolerance control and quality inspection to ensure that every detail is up to standard, thus guaranteeing the efficient operation and long life of the spur gear shaft.

Heat treatment

Heat treatment is a key step to improve the mechanical properties of spur gear shaft, including quenching, tempering and other processes. By precisely controlling heating and cooling rates, the microstructure of the material is changed to enhance hardness and wear resistance. Proper heat treatment can not only increase the service life of the spur gear shaft, but also optimize its fatigue resistance and ensure reliability under heavy load conditions.

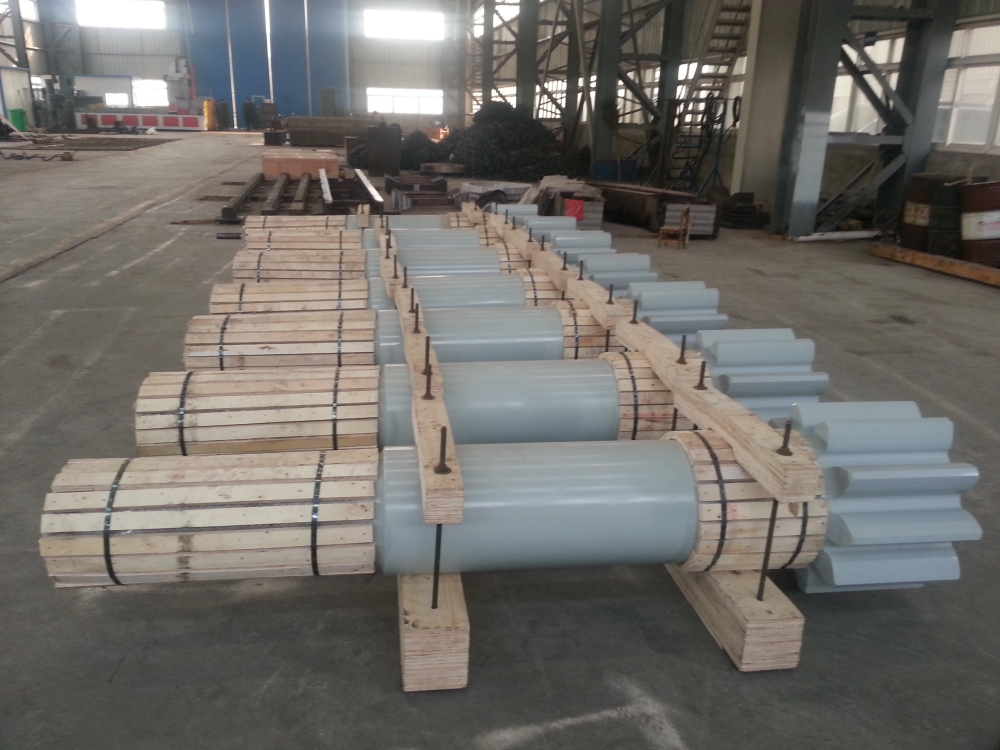

Package of Spur Gear

Oiling or Coating: Applying a thin layer of rust-preventative oil or another protective coating can shield the surface from moisture and contaminants.

Packing: fumigation-free wooden case customized according to product size. If necessary, a steel frame will be welded to the outside of the wooden box to assist the operation of the forklift truck.

FAQs of Spur Gear

1.What module of gear can you produce? –8-120

2.What is the accuracy grade you can achieve? –6-8

3.What kind of payment terms do you have? –T/T & L/C

4.Whether to provide samples? –No

REQUEST A QUOTE

RELATED PRODUCTS

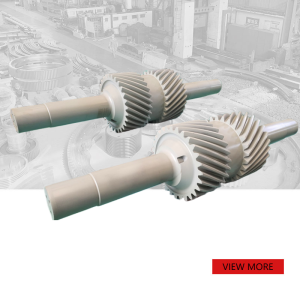

Custom forged steel large helical gear shaft

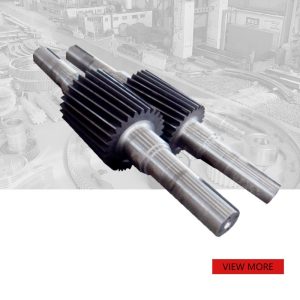

Rotor Shaft for Crusher

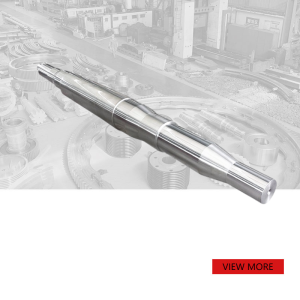

Spur gear shaft forging high quality large diameter Ball Mill

Customized hammer crusher long service life wear resistant rotor shaft

34CrNiMo6Custom Reducer Herringbone Gear Shaft with tool return groove