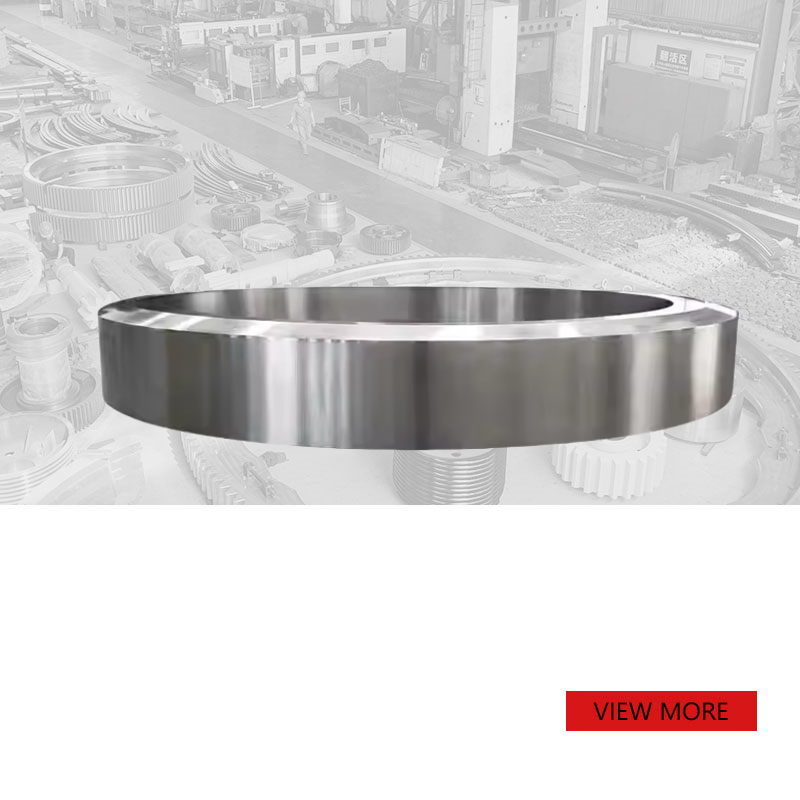

Non-standard custom high quality 42CrMo forging ring

PRODUCT PARAMETERS

Description

一. Overview of Forging Ring

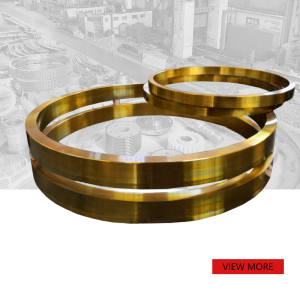

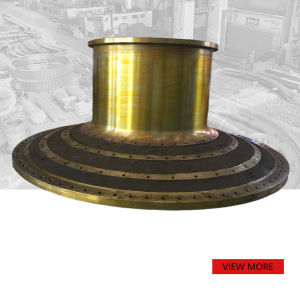

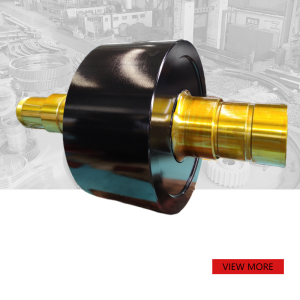

Forging ring are ring-shaped components manufactured from metal materials through forging processes. They possess high strength, toughness, and excellent wear resistance. 42CrMo, as a high-quality alloy steel material, is widely used for producing high-quality forging ring due to its outstanding mechanical properties. These rings undergo multiple heat treatments and precision machining during production to ensure uniform internal structures and defect-free qualities, meeting the demanding requirements of harsh working conditions. The dimensions and shapes of forged rings can be customized according to specific needs, making them suitable for various complex applications.

二. Applications of Forged Rings in the Mechanical Processing Industry

Forging ring have widespread applications in the mechanical processing industry, primarily used in critical areas that need to withstand high loads and dynamic stresses, such as bearings, gearboxes, and connectors. Owing to their exceptional strength and toughness, 42CrMo forged rings are particularly suited for key components in heavy machinery, aerospace, and petrochemical equipment. Additionally, forged rings are commonly employed in rotating machinery like turbines and compressors to achieve efficient power transmission and distribution. Their main role in these applications is to provide stable support and reliable connections, ensuring the safe operation and long service life of the entire mechanical system.

三. General Production Process of Forging Ring

1. Material Selection and Preparation

– Material Selection: Choose suitable metal materials based on application requirements, such as 42CrMo alloy steel.

– Material Inspection: Conduct chemical composition analysis and mechanical property tests on raw materials to ensure they meet design specifications.

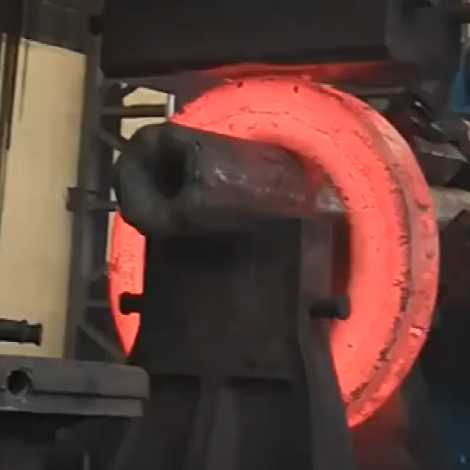

2.Forging

– Open Die Forging: Gradually form the metal billet into the desired ring shape through hammering and rolling. This step may require multiple iterations to achieve the target shape and dimensions.

– Ring Rolling: Use specialized ring rolling machines for continuous rolling, gradually expanding the ring diameter and reducing wall thickness until the design specifications are met.

3.Heat Treatment

– Normalizing/Annealing: Improve internal material structure and enhance mechanical properties through normalizing or annealing treatments.

– Quenching + Tempering: Perform quenching to increase hardness, followed by tempering to reduce internal stresses and improve toughness.

4.Machining

– Turning and Milling: Remove excess material to form the basic contour and prepare for subsequent precision machining. This stage leaves appropriate machining allowances for finishing steps.

5.Quality Inspection

– Non-destructive Testing: Including ultrasonic testing and magnetic particle inspection to check for internal cracks or other defects.

– Dimensional Measurement: Use coordinate measuring machines (CMM) and other equipment for precise dimensional inspections to ensure all critical dimensions meet drawing requirements.

6.Packaging and Shipping

– Cleaning and Rust Prevention: Clean the finished products and apply rust preventive oil or other anti-corrosion measures.

– Packaging: Use appropriate packaging materials to protect the products, ensuring they are not damaged during transportation.

The entire production process requires strict quality control at each step to ensure that the final product’s performance and service life meet expected design requirements. In practical production, specialized equipment and tools may also be involved, along with optimization of specific process parameters.

四.FAQs of forging ring

-How long is the delivery time? 45-80 days

-What are the packaging methods?

According to customer requirements, plywood boxes are generally used.

-Do you accept third-party inspection? Yes