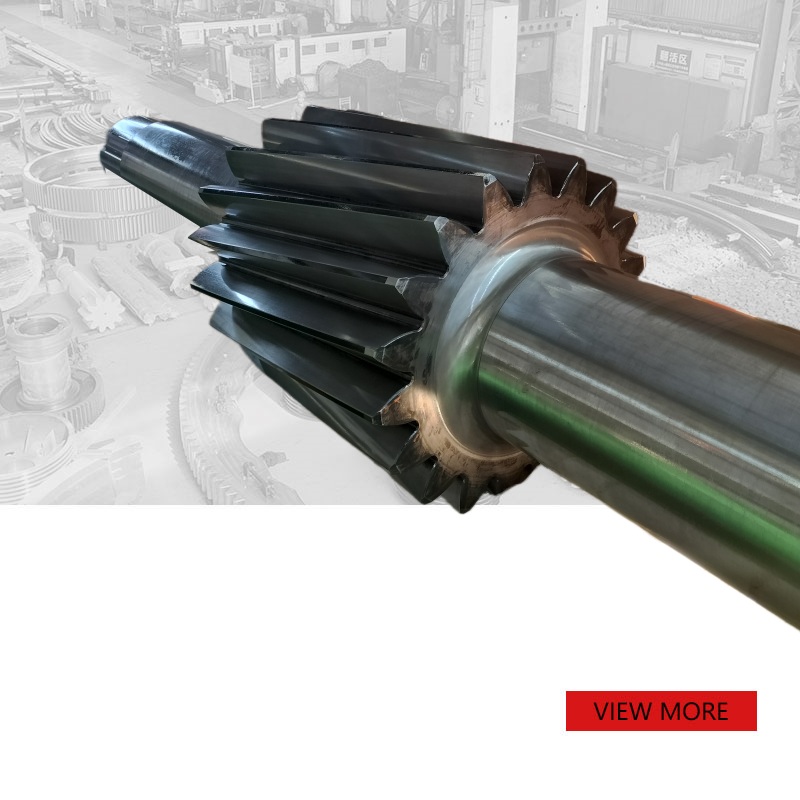

Custom Forged 42CrMo Non-standard Gear Shaft

PRODUCT PARAMETERS

Description

一. Overview of Large Module Gear Shaft

Large module gear shafts refer to those with a larger module value, typically used in applications that require high load-bearing capacity and high strength. 42CrMo, as a high-quality alloy steel material, is often utilized for manufacturing such gear shafts due to its excellent mechanical properties, including high strength, toughness, and superior wear resistance. The design and production of these gear shafts must adhere to strict process flows to ensure their stability and durability under complex working conditions.

二. Applications of Large Module Gear Shaft

Large module gear shafts are widely used in heavy-duty machinery, such as metallurgical equipment, mining machinery, and marine propulsion systems, where efficient power transmission and the ability to withstand heavy loads are required. Their primary role in these applications is to achieve efficient torque transmission and power distribution through precise tooth profile designs and superior material characteristics, ensuring smooth operation of the entire mechanical system. Additionally, due to their high strength and wear resistance, they are also suitable for work conditions involving frequent starts and stops.

三. Main Production Process:

The production process of large module gear shafts is a complex and meticulous one, involving several steps and technologies.

1. Material Selection and Preparation:

– Select high-quality steels suitable for high-load applications, such as 42CrMo, and determine material specifications based on design requirements.

– Inspect raw materials to ensure their chemical composition and mechanical properties meet standards.

2.Forging :

– Use techniques like hot die forging or cross wedge rolling to shape raw materials into near-final form blanks, improving internal material structure and reducing subsequent machining volume.

3.Heat Treatment:

– Perform quenching and tempering to enhance material strength and toughness.

– Depending on requirements, surface hardening treatments such as carburizing or nitriding may be included to increase surface hardness and wear resistance.

4. Finish Machining:

– Include operations like gear grinding, hobbing, and broaching to achieve the desired precision levels.

– Multiple adjustments to tools and fixtures may be necessary to ensure precise tooth profiles.

5. Quality Inspection:

– Conduct comprehensive quality checks on finished products, including dimensional measurements, hardness tests, and flaw detection, to ensure compliance with technical specifications.

The entire production process requires strict quality control at each step to ensure the final product’s performance and service life meet design expectations. In practical production, specialized equipment and tools may also be involved, along with optimization of specific process parameters.

6.Packaging

-Bracket

Low cost, poor protection effect, suitable for gear shafts with average precision on mines and engineering machinery

四.FAQs of shaft

-How long is the delivery time? 45-80 days

-What are the packaging methods?

According to customer requirements, plywood boxes are generally used.

-Do you accept third-party inspection? Yes

REQUEST A QUOTE

RELATED PRODUCTS

Custom mining forging long helical gear shaft

Spur gear shaft forging high quality large diameter surface quenched

Custom forged 42CrMo large modulus gear shaft

Custom High Quality 42CrMo Forged Steel Pinion Shaft

Mining Forging 34XH3M large module spur gear shaft