About Us

Company

Advantage

Factory

Honors

Who We Are

WE ARE A MACHINERY PARTS BRAND

Established in 2002, Luoyang Wangli Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. Our factory located in Luoyang, one of important base for heavy machinery in China. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

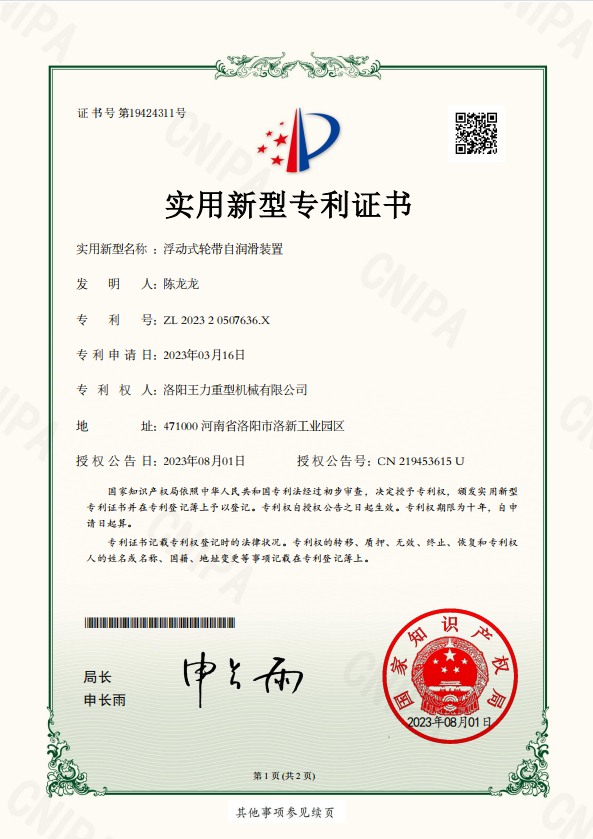

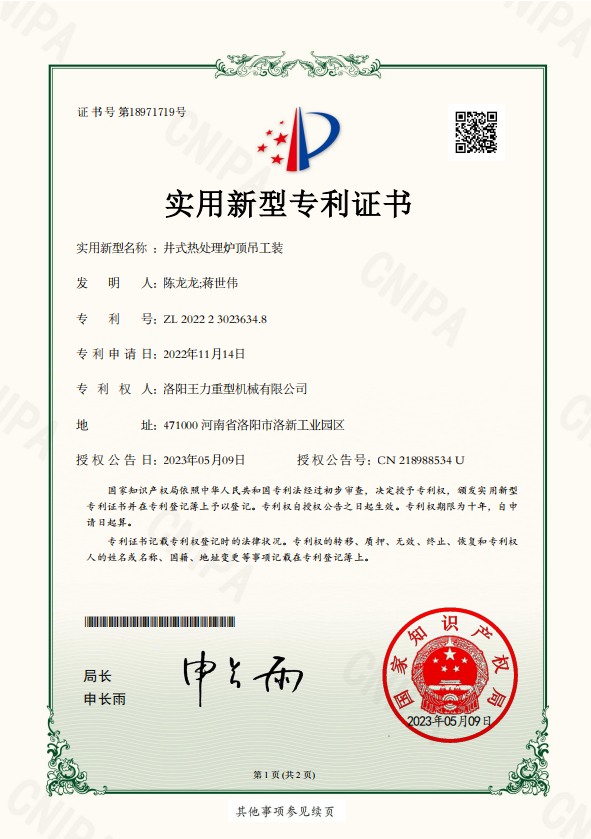

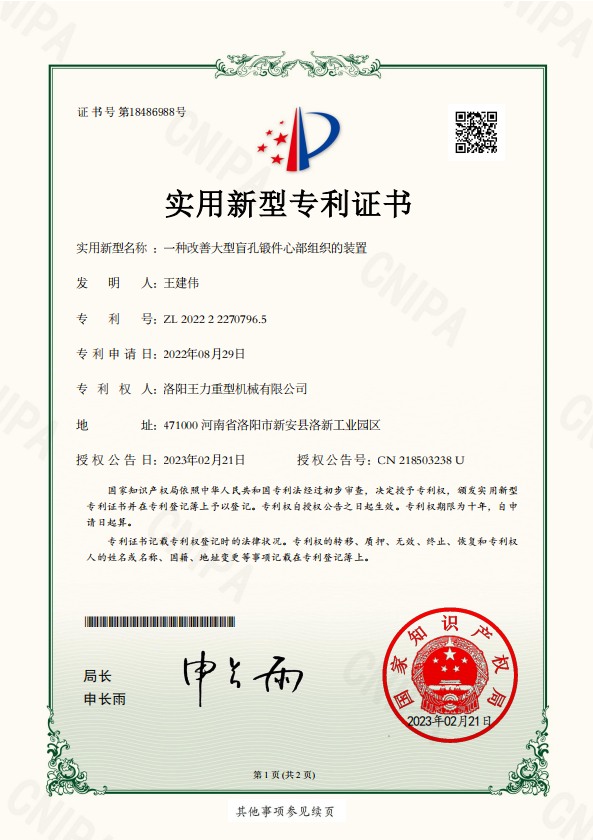

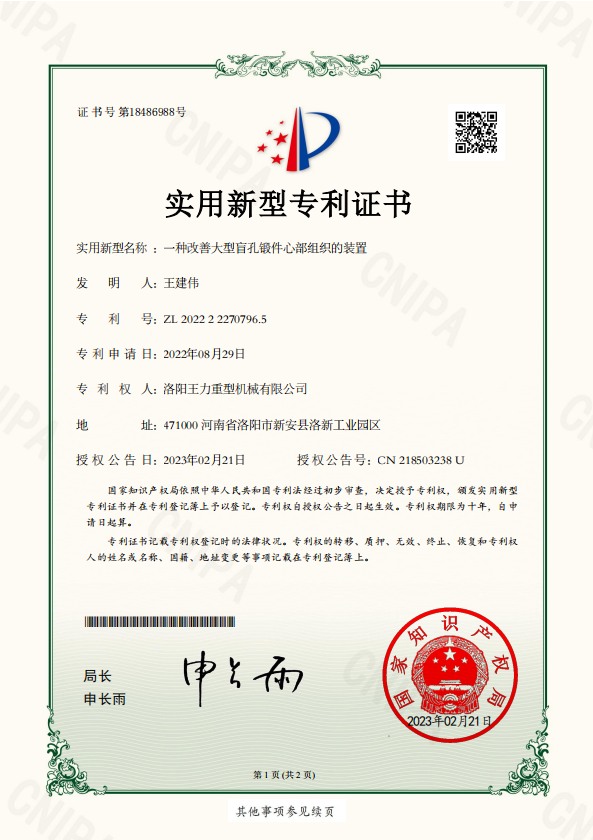

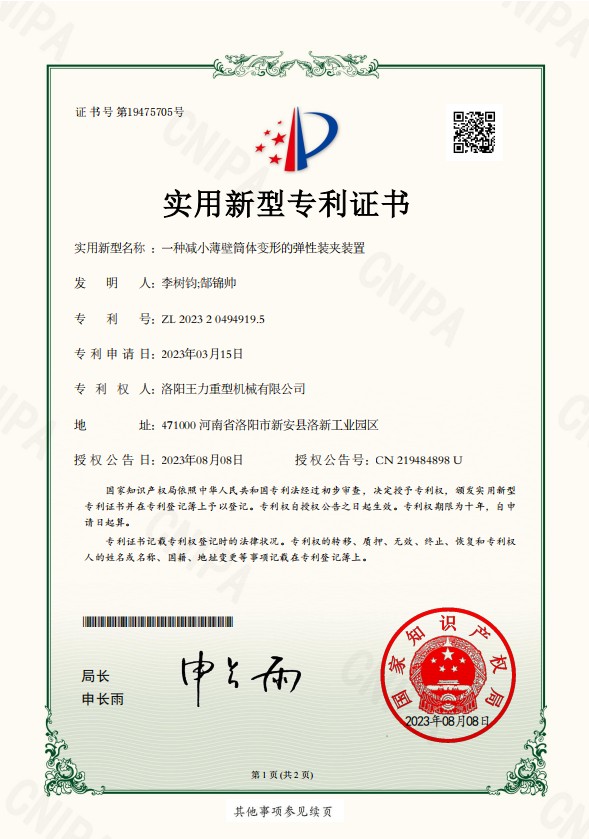

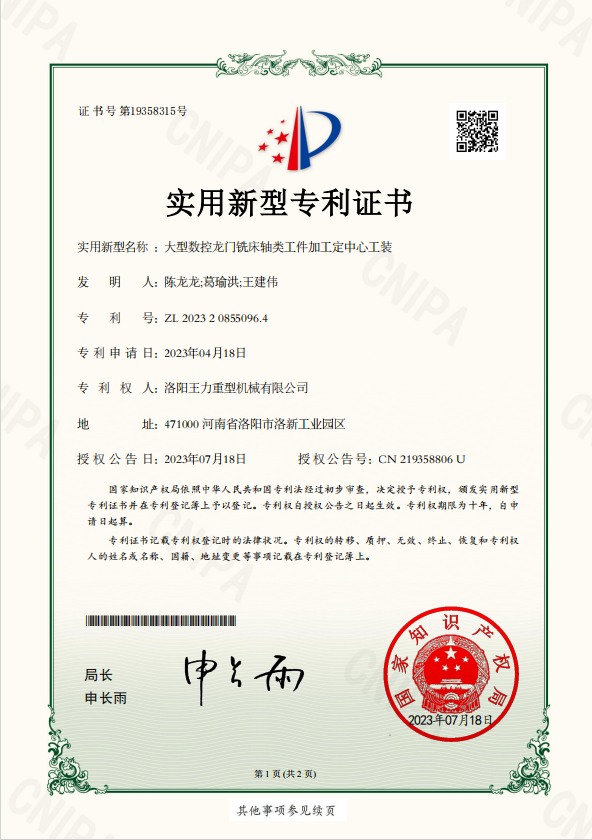

Our mainly products: dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

Our mainly products: dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

Over the past 15+ export experience, we have served 200+ compaies in 50+ countries and regions, During these times, three international key projects, such as key spare parts of military products, segment girth gear used in the Suez Canal in Egypt.

We believe that innovation is the key to success and attracts talents who can think differently. Together, we can make a real difference.

We believe that innovation is the key to success and attracts talents who can think differently. Together, we can make a real difference.

0

YEAR OF EXPERIENCES

90

PROFESSIONAL TEAM

0

CUSTOMER REVIEWS

0

PRODUCTS SOLD

Our Advantage

WHY CHOOSE US

Industrial experience

40+ years experiences focus on metal research and mining machinery spare parts. Approval technology supports and on site surveying and mapping.

Key Project

Three international key projects, such as key spare parts of military products, Segment girth gear used in the Suez Canal in Egypt.

Equipments & Capacity

Besides five workshops, 100+ sets of equipment, capability of integrating equipment resources from 300+ enterprises.

Technical Support

8 material senior engineers and 40+ patents and enterprise standard. 6 sets of vertical-type electric furnaces and 4 kinds of quenching medium.

Market

Over 95% repeat customers, 15+ Years export experiences who have served more than 200+ companies in 50+ countries and regions.

Quality Control

100% UT & QC inspection, approval customer personally inspection & the third party & online test.

Our Factory

OUR FACTORY

PATENTS & certificate