Mining Machinery Gear Technology: Driving a New Chapter in Mining Efficiency and Safety

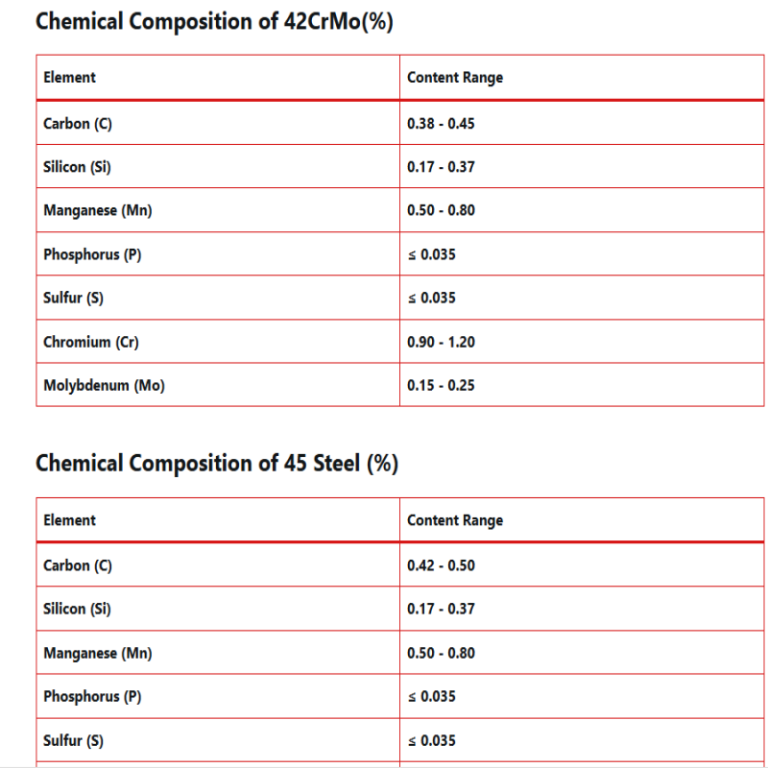

Gear Basics: Definition and Importance

A gear is a mechanical component with teeth that transmits rotational motion and power through meshing with another gear or a component with a rack. They are an indispensable part of many mechanical equipment, especially in the field of mining machinery, where gears can not only change speed and torque but also achieve precise position control. The design and material selection of gears directly affect the overall performance, efficiency and life of the equipment.

Wangli Gear

Common Gear Types in Mining Machinery

Spur Gears: As one of the most basic and widely used gear types, spur gears are suitable for a variety of applications with their simple design, especially under low speed and high torque conditions. This type of gear is easy to manufacture and relatively low in cost, but its disadvantage is that it generates loud noise and may cause vibration problems when running at high speeds.

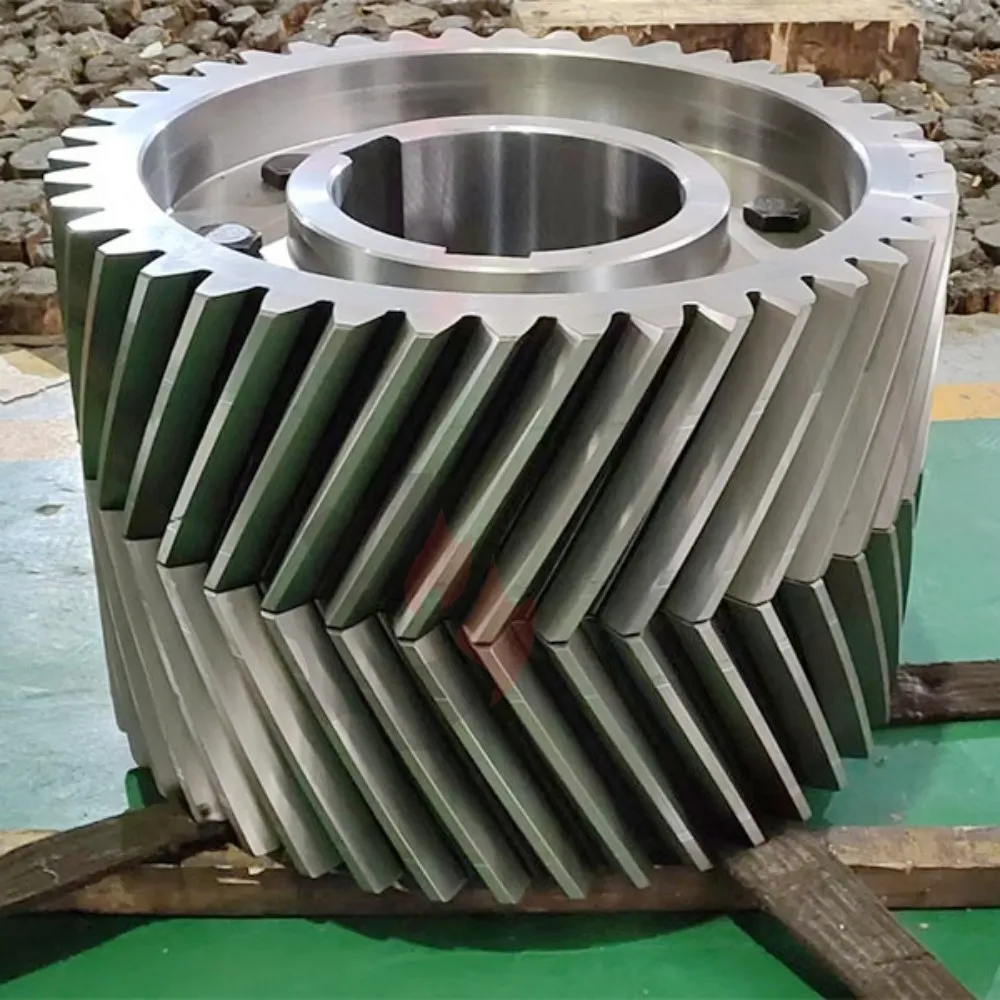

Helical Gears: Compared with spur gears, Helical Gears have an inclined tooth design, which enables them to provide smoother power transmission during work and effectively reduce noise levels. In addition, helical gears have better load distribution characteristics due to the wider contact surface, so they can maintain high efficiency even when subjected to heavy loads. However, the working principle of helical gears leads to the existence of axial forces, and additional measures are needed to balance this force.

Bevel Gears: Bevel gears are ideal when power needs to be converted from one axial direction to another. They are widely used in occasions such as mine hoists to ensure that power transmission tasks can be completed efficiently even when the angle changes. Bevel gears can be divided into two main forms according to specific needs: straight bevel gears and spiral bevel gears.

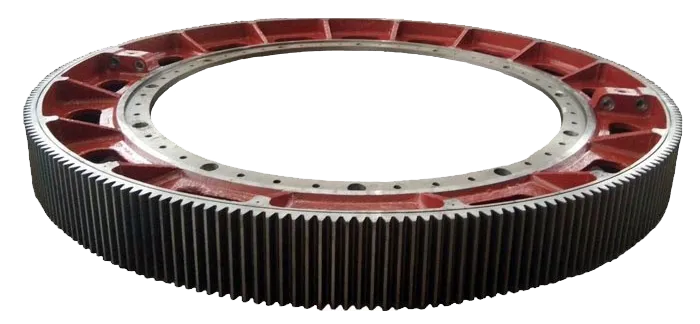

Planetary gear system: This system consists of a central sun gear, multiple planetary gears rotating around it, and an external ring gear. It is known for its compact and efficient structure. Planetary gear systems are very suitable for applications where space is limited but high performance output is required, such as certain types of mining drilling equipment.

Worm gear: For situations where a large reduction ratio is required, the worm gear combination is a good solution. This type of gear is particularly suitable for heavy mining machinery, such as crushers and mills, where it is often necessary to convert fast rotation at the input end into slow, high-torque output at the output end.

Wang Li Helical Gears

A Deep Look at Helical Gears in Metallic Gears

In the field of mining machinery, helical gears are highly favored for their excellent performance. In addition to the advantages mentioned above, modern helical gears also use advanced material processing technologies, such as surface hardening, to further enhance wear resistance and fatigue resistance. In addition, in order to overcome the axial thrust problem of traditional helical gears, engineers have developed a double helical gear design, that is, two helical gears with opposite rotation directions are installed on the same shaft to achieve the effect of offsetting each other’s axial forces.

How to Find Gear Ratio

The gear ratio refers to the ratio of the speeds between two meshing gears. It is one of the important parameters for measuring the working efficiency of a gear set. The calculation method is relatively intuitive: if the number of teeth on the driving wheel (driving wheel) is known to be \(Z_1\), and the number of teeth on the driven wheel (driven wheel) is \(Z_2\), then the gear ratio is \(i = \frac{Z_2}{Z_1}\). This means that if you want to increase the output torque while reducing the output speed, you should choose a larger gear ratio and vice versa. In practice, by adjusting the combination of gears of different sizes, you can flexibly meet the needs of various working conditions.

Wangli Factory

Supplier

Wangli Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. Our factory located in Luoyang, one of important base for heavy machinery in China. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008. If you need gear, please feel free to contact us.(12345@wangli.com)

Contact us