What is the gear ratio of a worm and wheel?

A ratio between a wheel and worm gear (also referred to as “worm gear“) can be determined by how many teeth exist on the wheel gear since most worms consist of just one thread that acts as one “tooth.” For instance, if a wheel contains 40 teeth, then this represents a ratio of 40:1, meaning its gears must complete one full turn for every 40 turns made by its counterpart on its counterpart (i.e., the ratio equals 1 for every turn performed by its partner worm gear).

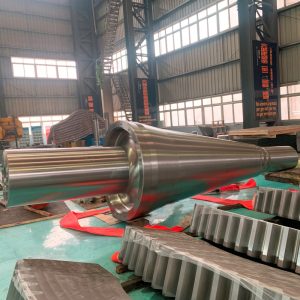

Worm gear and wheel

Let me elaborate:

1. A worm gear resembles a screw with its helical threads connecting with the teeth of the wheel gear.

2. Each complete turn of the worm only increases one tooth on the wheel.

3. Therefore, if a wheel contains N teeth, the ratio is N:1.

4. Common ratios vary from 20:1 up to 100:1, or even higher.

Worm gears offer one of the key benefits of any gear system. Their highly high reduction ratio allows them to decrease speed while significantly increasing torque. They’re widely used in conveyor systems, elevators, and heavy machinery where torque must be reduced considerably.

Worm gears are known for their built-in self-locking feature, which stops the worm from turning the wheel because of the strong friction forces involved. This quality is valuable in situations where stopping backward movement is essential, like securing loads in place.

Let’s investigate the critical uses of worm gears in mining machinery.

Conveyor drive systems: Worm gears provide a reliable means of reducing speed while increasing torque, making them a good fit for moving extracted materials. Their locking feature also prevents materials from backtracking on inclined conveyors.

Mining winches and hoists: Worm gears’ self-locking properties enable the safe lifting of heavy loads in mine shafts, reducing the risk of uncontrolled descents.

Roof support systems: Worm gears are used in hydraulic roof supports to provide precise control over movement and load holding, which is critical for maintaining mine safety.

Portable Mining Machinery:

Mining trucks and loaders utilize worm gears for precise steering that is resistant to shocks. Crawler-mounted mining equipment relies on track drives for dependable power distribution and movement regulation. Mechanisms with high reduction ratios and load-holding capabilities effectively control equipment arms and booms.

The maintenance advantages and benefits in the mining industry are evident in the durability of this type of equipment, which can withstand sudden impacts better than other options. When adequately protected, it shows impressive longevity in settings with a lot of airborne particles. Its compact design is advantageous in confined mining spaces, allowing for better space utilization. Moreover, the equipment requires less frequent maintenance due to having fewer moving parts.

Are there any specific mining applications you’d like me to explore in more detail, or would you want me to discuss the technical benefits of worm gears in specific mining environments?

If you need worm gear and wheel, don’t hesitate to get in touch with luoyang wangli heavy machinery co.,ltd: lulu@citicwl.com