Solutions for Enhancing the Service Life of Large Module Gear Shaft

In mechanical transmission, large-module gears/ shaft play a critical role as key components, and their performance and lifespan are crucial to the reliability of the entire system. To extend the service life of these gears, we propose an all-encompassing solution focusing on design optimization, material selection, heat treatment technology, unique processes, and stringent quality inspection.

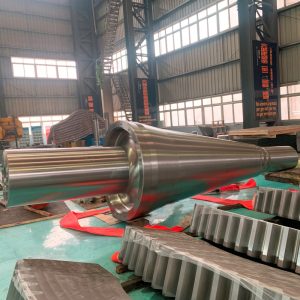

large module gear shaft

I. Professional Assurance in Design

Drawing from over 40 years of industry experience in large module pinion shaft, our expertise allows us to provide rational suggestions and offer improvement plans tailored to specific application environments. Our team is capable of on-site measurement and can customize gear designs according to actual working conditions, ensuring that each product meets particular operational requirements.

II. Selection of High-Quality Materials

We adhere to high standards in material selection, employing advanced methods such as refining furnaces to reduce the content of harmful elements like sulfur, phosphorus, oxygen, and hydrogen, thereby enhancing material purity. The forging ratio exceeds 5, surpassing international standards, which provides superior mechanical properties for the gears. We also supply materials according to ASTM/DIN/EN/GOST ect international standards , ensuring a high-quality product starting point.

III. Advanced Heat Treatment and Processing Coordination

Heat treatment is a decisive step in determining gear performance. Equipped with well-type electric furnaces featuring German temperature control systems, we achieve precise temperature control within ±1℃. Moreover, four quenching media can be flexibly combined based on process needs, making the heat treatment process more accurate and efficient. Notably, our heat treatment workshop is adjacent to the processing workshop, allowing for prompt stress-relief annealing after processing, effectively preventing deformation and improving the stability and durability of the gears.

IV. Application of Special Processes

Before tempering, we apply rough tooth cutting, a unique process that facilitates uniform internal stress distribution during subsequent heat treatment, thus strengthening the gear’s overall integrity.

V. Strict Inspection Procedures

Each large-module gear undergoes 100% ultrasonic testing and magnetic particle inspection of the tooth surface to ensure no hidden defects exist. This comprehensive inspection significantly enhances product quality and reduces the likelihood of failures.

VI. Customized Services

To better serve our clients, we offer various customized services, including surface hardening, carburizing, nitriding, and other gear treatment treatments, to adapt to different operating conditions and customer requirements.

In conclusion, this solution aims to substantially increase the lifespan of large-module gears through multi-faceted efforts, providing more reliable support for industrial transmission systems.

-300x300.jpg)