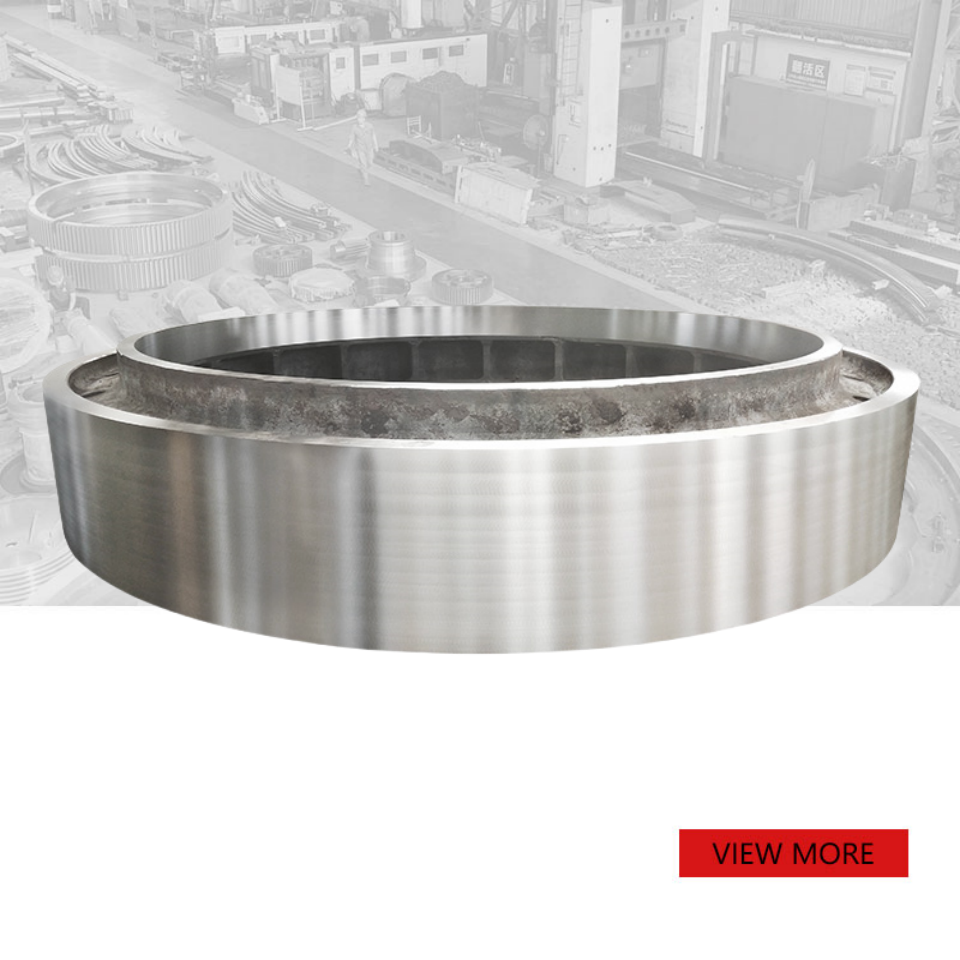

35# custom heavy duty wear-resistant cement kiln Tyre

PRODUCT PARAMETERS

Description

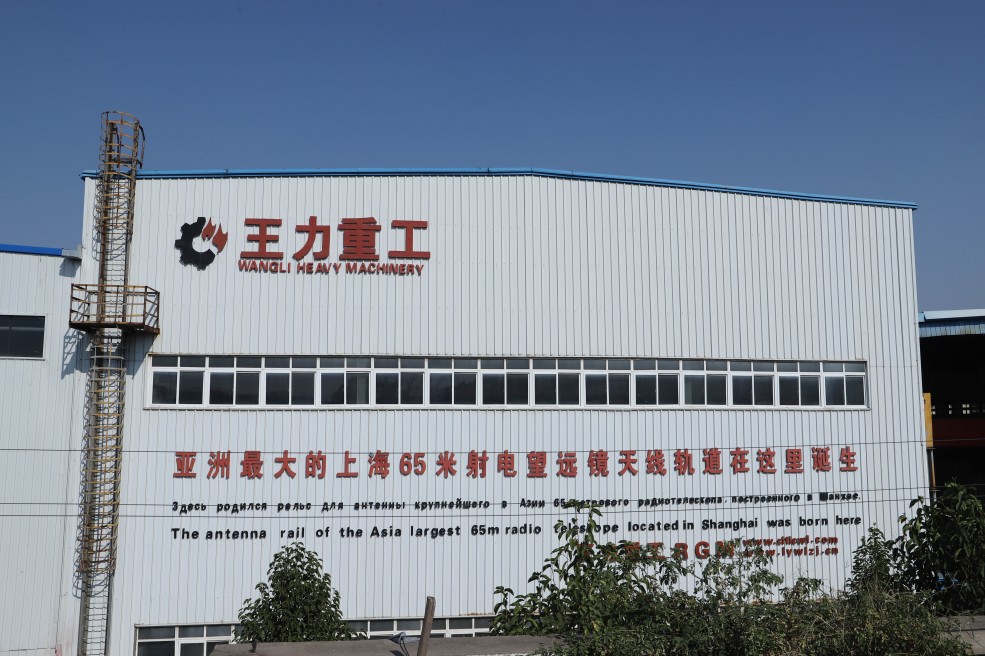

一. Company overview

Luoyang Wangli Heavy Machinery Co., Ltd. was established in 2002. We’re a national high-tech enterprise, a contract-honoring and trustworthy enterprise in Henan Province, a quality benchmarking enterprise in Luoyang.

We have 40+ patents and a team of more than 30 years experts with experience in large state-owned enterprises.

Main products: Cement kiln spare parts,Dragline spare parts, Crusher parts, large modulus gear parts, hot forging dies, customized large non-standard mechanical parts.

We have been exported to 50+ countries and regions.

We believe that :”Material is the skeleton for one machinery, while production design is the though, CNC machining is the essence and heat treatment is the soul”

二. Product Description

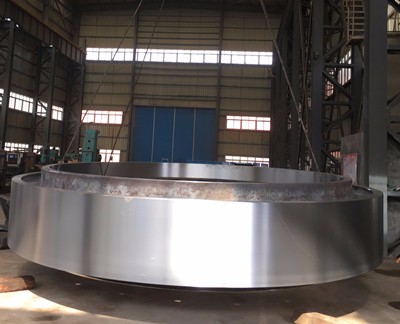

The kiln tyre of cement kiln is the key component of grinding operation in mining, metallurgy, building materials and other industries, which surrounds the outer edge of the ball mill shell to support and transmit power.

It withstands great pressure and friction, requiring wear-resistant materials and high strength to ensure stable operation and long service life of the equipment.

三.Production process

- Casting

Material is the skeleton for one machinery, while production design is the though, CNC machining is the essence and heat treatment is the soul.Our casting engineers are on-site to supervise the casting process and ensure the high quality of the materials

2.Rough machining

Vertical Lathe Horizontal Lathe

Φ0.5-8 meters vertical lathe, more than 20 years working experience skillful workers.

3.UT

In our internal quality control system, UT is performed on every workpiece

to ensure that each product has no internal defects

4.QT

We have our own heat treatment workshop.

6 Sets of well-type electric furnace and complete quenching medium can meet the heat treatment requirements of different materials and different specifications of products

5.Finished machining

According to customer requirements of different product size, processing accuracy

in different specifications of the vertical lathe

6.MT

Magnetic particle inspection of the kiln tyre(Casting) is carried out by professionals to ensure it has no external defects

- Packing & Delivery

We package our products in a manner suitable for export(Moisture-proof/Rust-proof/Anti-corrosion)

according to company policy and customer requirements

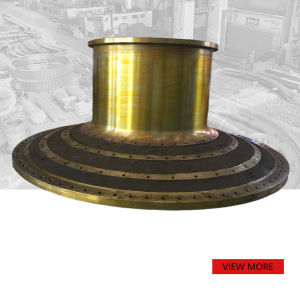

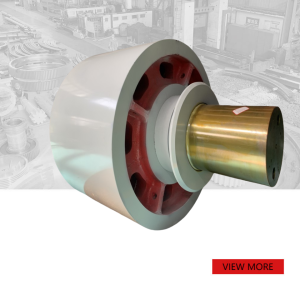

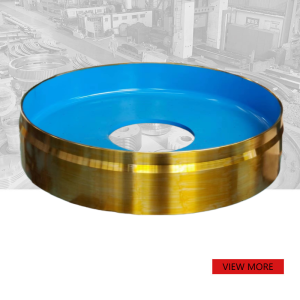

四.Related product