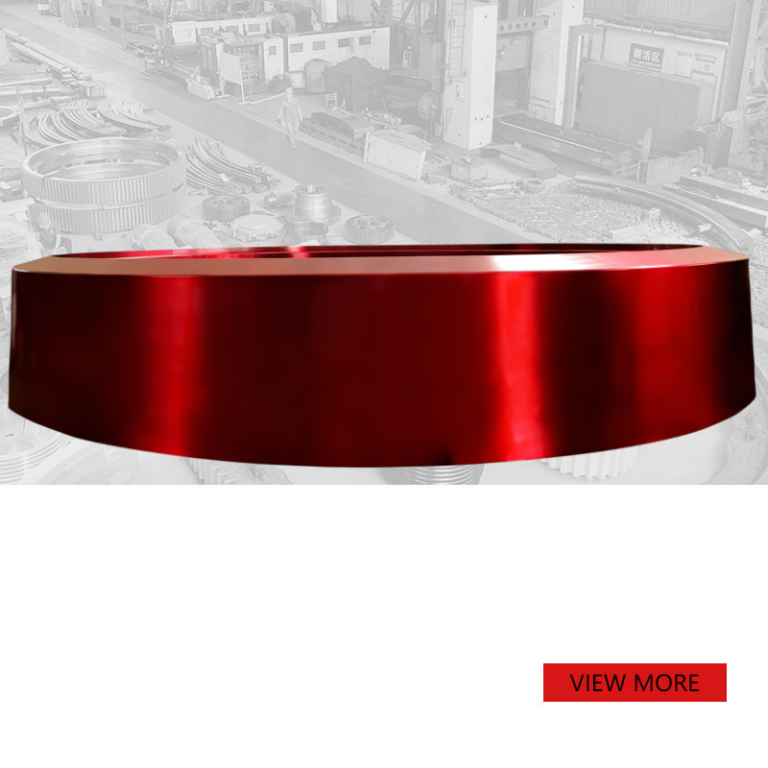

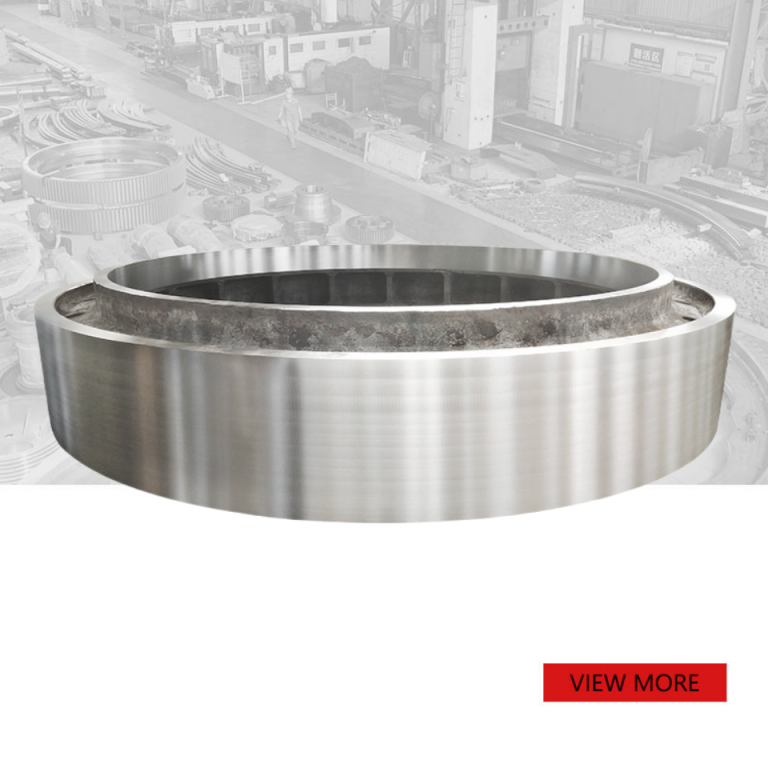

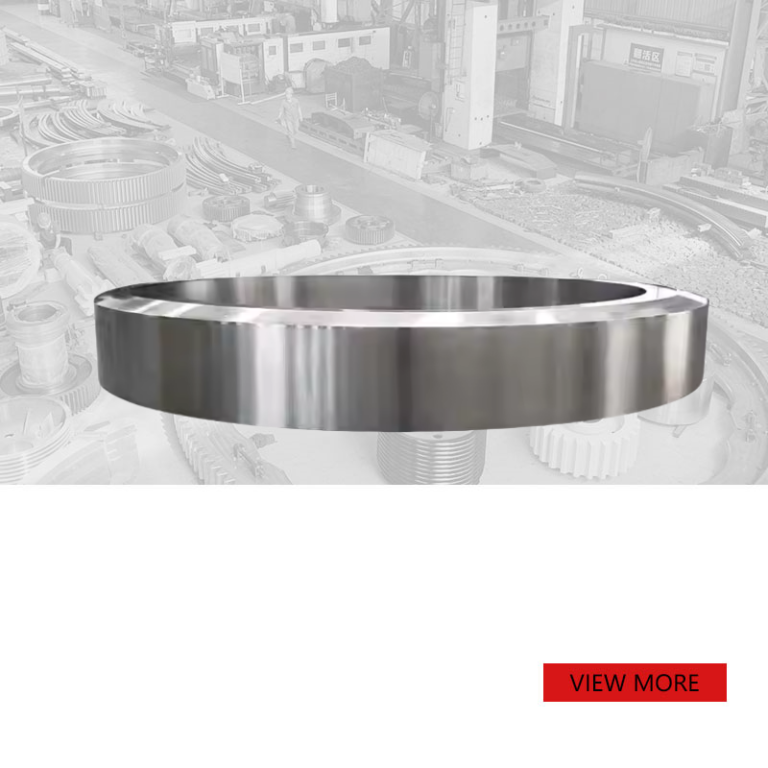

Custom Casting wear-resisting Rotary Kiln Tyre

PRODUCT PARAMETERS

Description

Rotary kiln tyre

Overview of rotary kiln tyres

The rotary kiln tyre, also known as the rolling ring, is one of the main components of the rotary kiln equipment. The main function of the rotary kiln tyre is to transfer the entire gravity of the cylinder (including the gravity of refractory bricks, internal devices and materials, etc.) to the support wheel and enable the cylinder to rotate smoothly on the support wheel. Therefore, the rotary kiln tyre needs to have sufficient strength and durability. At the same time, the rotary kiln tyre is also a part that strengthens the radial stiffness of the cylinder and should have sufficient stiffness to prevent deformation.

Classification and characteristics of rotary kiln tyre

According to the cross-sectional shape of the rotary kiln tyre, it can be divided into the following categories,

Solid rectangular tyre: simple shape, easy to ensure manufacturing quality, long service life, but relatively small stiffness, unreasonable material utilization, and poor heat dissipation conditions.

Box-shaped tyre: The cross-section is hollow box-shaped, with good thermal conditions and high rigidity, but the material utilization is more difficult.

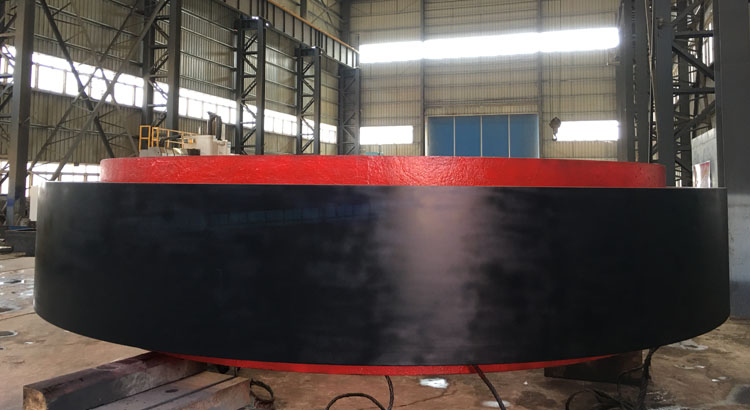

Installation method and function of rotary kiln tyre

The rotary kiln tyre is usually installed on the cylinder in a slip-on manner. The rotary kiln tyre is not directly installed on the cylinder segment but on the pad so that a natural ventilation channel is formed between the cylinder and the rotary kiln tyre. This installation method enhances heat dissipation, reduces the heat conduction of the kiln body to the rotary kiln tyre, makes the temperature difference between the inner and outer edges of the rotary kiln tyre smaller, and reduces temperature stress. In addition, when the kiln is running, the rotary kiln tyre and the cylinder will slide relative to each other in the axial direction, and the pad plays a role in protecting the cylinder.

Rotary kiln tyre material selection and requirements

The material of the rotary kiln tyre is generally high-strength steel, such as 35 steel, 45 steel, 35CrMo, 42CrMo, etc. Forged steel is the preferred material for making high-grade wheel rotary kiln tyres due to its high strength and good wear and corrosion resistance. In practical applications, the selection of rotary kiln tyre materials also needs to consider factors such as the working conditions and cost of the rotary kiln. Modern large-scale wheel rotary kiln tyres are mostly produced by casting technology, but attention should be paid to the problems of uneven axial hardness and loose structure of cast wheel rotary kiln tyres.

Application scenarios, common problems and maintenance of rotary kiln tyre

Rotary kiln tyres are widely used in cement, building materials, metallurgy, chemical industry and other industries. For example, in cement production, the rotary kiln tyre supports the rotation of the entire kiln body to ensure that the material is fully calcined in the kiln to achieve the production of cement clinker.The rotary kiln tyre may encounter problems such as wear, deformation, and cracks during use. These problems are usually caused by long-term operation, temperature stress, material fatigue and other factors. In order to maintain the good condition of the rotary kiln tyre, it is necessary to regularly check its wear and replace the damaged rotary kiln tyre in time; at the same time, keep the rotary kiln tyre and the pad clean and lubricated to reduce friction and wear.

Parameter Table of Rotary Kiln Tyre

| Material | Gs28Mn5, St60-2, 42CrMo4, |

| Diameter | 1000-8000mm |

| Width | 200-1500mm |

| Machining Surface Roughness | Ra6.3 |

| Ultrasonic Test | ISO 4992 |

Production Process Flow of Rotary Kiln Tyre

ultrasonic test for the casting rotary kiln tyre as customers’ required or Wangli company standard.

Packing & Delivery for Rotary Kiln Tyre

The packaging rotary kiln tyre materials is sustainable and recyclable, less impact on environmental. Over 15 years exported experiences can adapt most reasonable transportation methods and packaging plan.

Customer Review