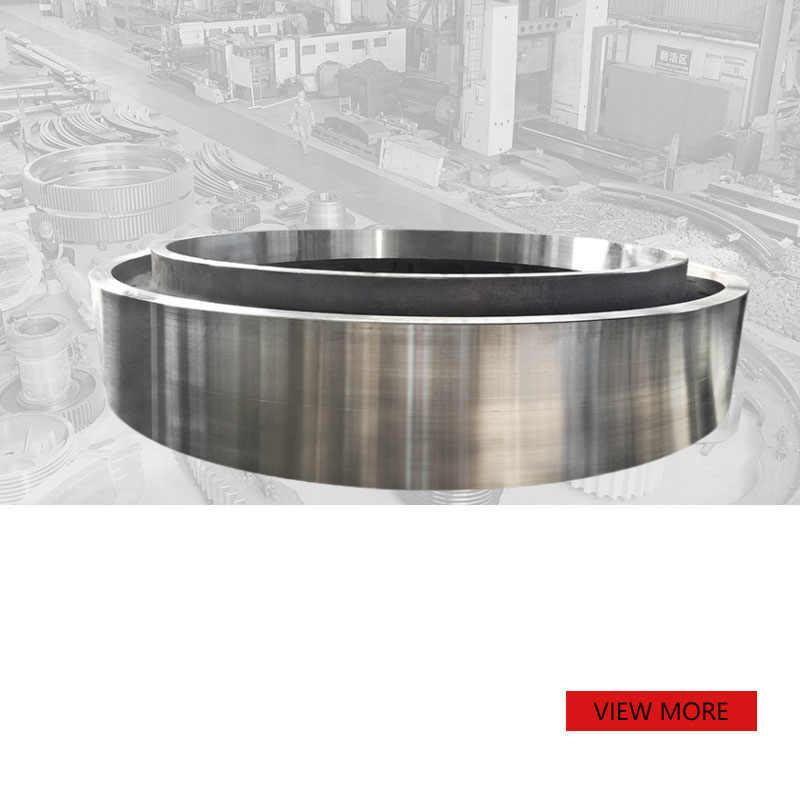

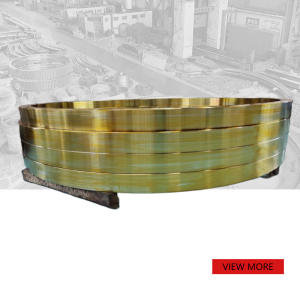

Custom large diameter Casting Rotary Dryer Kiln Tyre

PRODUCT PARAMETERS

Description

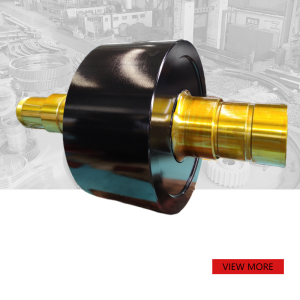

1.Overview of rotary kiln tyre tire

The rotary kiln tyre is a key component that supports and helps the rotary kiln body to rotate during the production process. It is mainly made of high-strength alloy steel to ensure stable operation under high temperature and high pressure environment. The design of the tyre needs to consider wear resistance, fatigue resistance and good mechanical properties to meet the requirements of continuous operation. Its quality directly affects the safety and work efficiency of the rotary kiln.

2.Application of rotary kiln tyre

The rotary kiln tyre is widely used in cement, metallurgy, chemical industry and other industries, mainly used to support and drive the rotary kiln to rotate smoothly. By using it in conjunction with the support wheel, the tyre can effectively disperse the weight of the kiln body, reduce friction resistance, and thus reduce energy consumption. In practical applications, it needs to withstand complex stress states, including gravity, thermal stress and dynamic loads, so it has high requirements for materials and manufacturing processes.

Parameter table

| Material | Carbon steel, alloy steel, as required |

| Standard | ASTM DIN, EN GOST JIS, etc. |

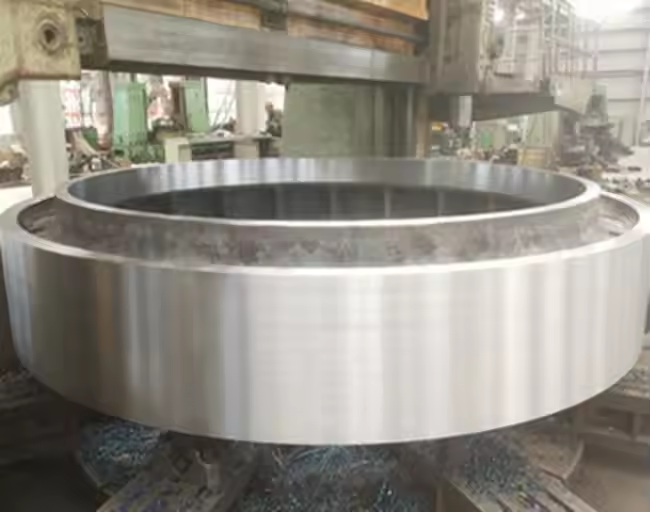

| Diameter of rotary kiln tire ring | 1000-7000 mm |

| Height of rotary kiln tire ring | 120-2000 mm |

| Structure | Casting and forging |

| Surface roughness | Ra 3.2 and 6.3 |

| Original Equipment Manufacturer (OEM) service | According to customer drawings |

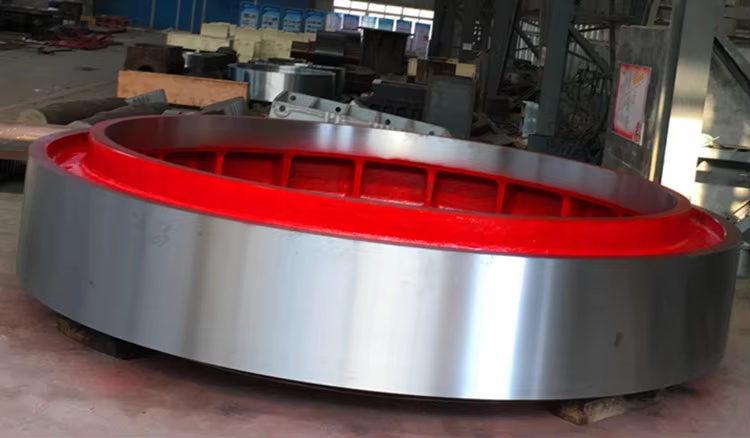

3.Production process of rotary kiln tyre

The production of rotary kiln tyre mainly includes casting, forging, heat treatment, machining and other steps.

First, select suitable high-strength alloy steel for casting or forging to form the basic shape of the tyre.

-Casting

This is the first and important step to control the quality of steel from the material. We can cast 1500-30000 kg/piece.

-Heat treatment process

Improve the hardness and wear resistance of the material.

-Rough processing

The diameter of the cast steel rotary kiln tire ring for large customized ball mill cement plant processing is 500-13000 mm.

Our largest lathe diameter is 15 meters.

-Finishing

Finally, after a precise machining process, ensure that the dimensional accuracy and surface quality of the wheel band meet the design requirements. The entire manufacturing process strictly follows national standards and industry specifications to ensure product quality.

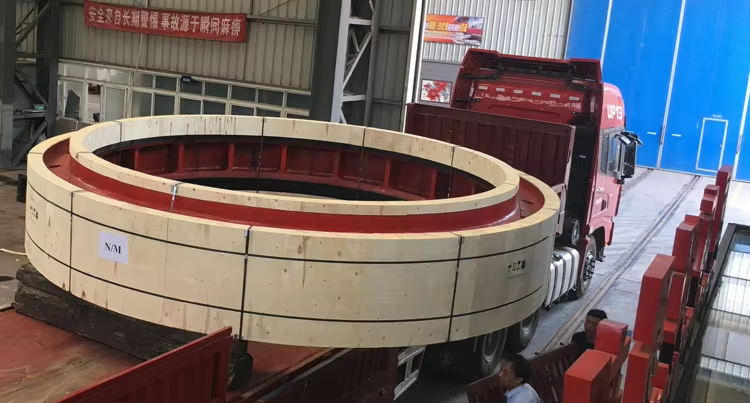

-Packaging

Packaging rotary kiln tire In order to avoid rust and damage of the finished product during transportation, we will design appropriate packaging according to the shape, size and purpose of the product.

4. Related products

Related products include but are not limited to: various specifications of rotary kiln wheel bands, support wheels, retaining wheels and their accessories, etc. These components work together to ensure the efficient and stable operation of the rotary kiln equipment. In addition, there are special material tyres customized for specific industrial needs, such as products with high temperature resistance, corrosion resistance and other properties, which are suitable for more harsh working environments.

REQUEST A QUOTE

RELATED PRODUCTS

Custom large diameter rolling steel hot forging ring

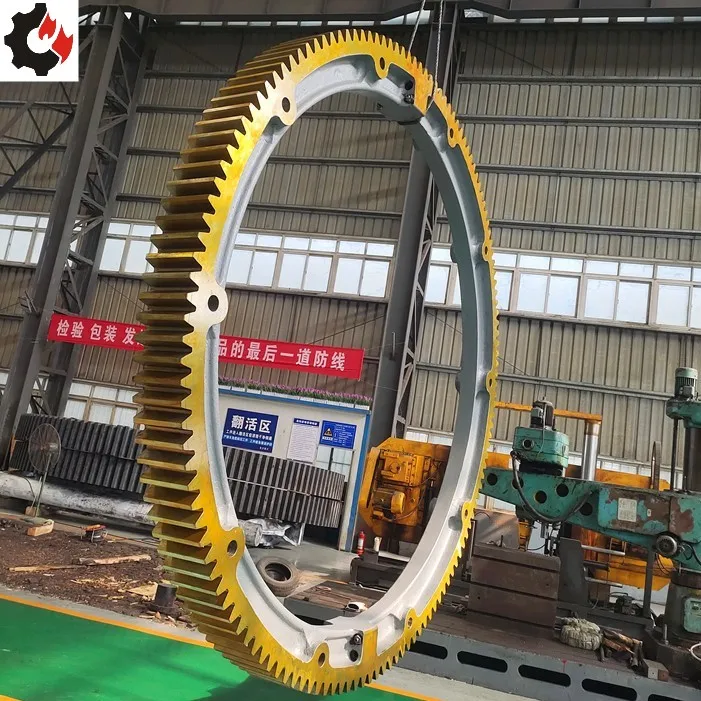

Non-standard customized rotary kiln casting gear ring

Custom forging large support roller

Customized cement kiln heavy duty 45# supporting roller

Customized Large dimeter rotary dryer 42CrMo forged ring