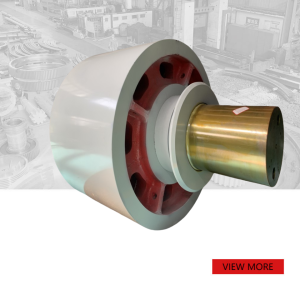

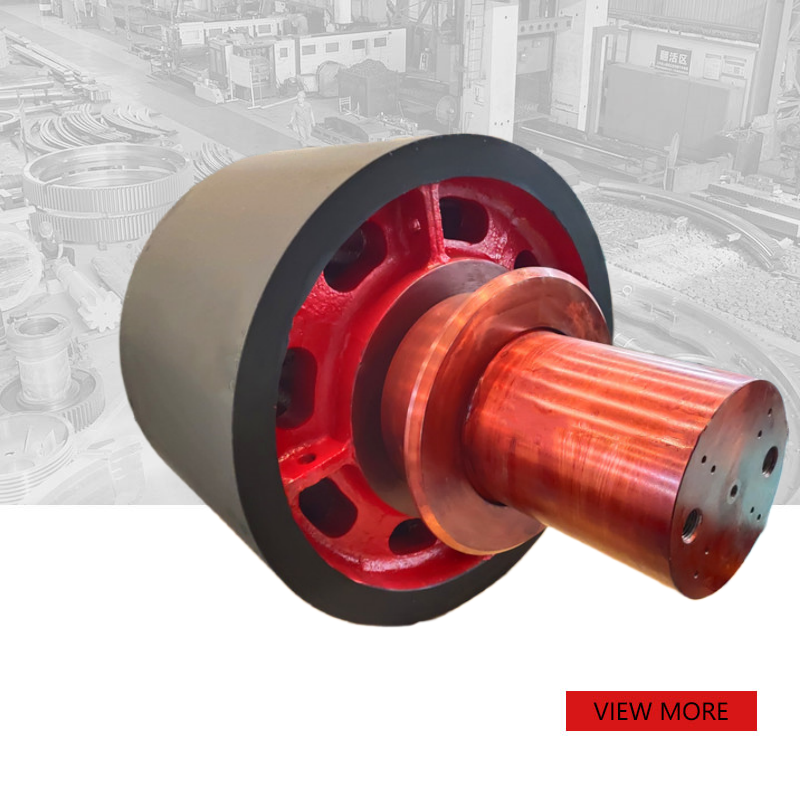

Customized cement kiln heavy duty 45# supporting roller

PRODUCT PARAMETERS

Description

- Description

| Material | Carbon steel, Alloy steel |

| Structure | Forging/Casting |

| Heat treatment | QT |

| Surface treatment | Surface hardening |

| Parameters | According to drawings |

二. Usage

In large rotary equipments, the supporting roller is used to support the rotary kiln and allow it to rotate smoothly.

For example, the cement industry, ball mills in mining, cranes, steel mills and other industries. They also help to position the cylinder and ensure that it is properly aligned, which increases work efficiency and extends equipment life.

三. Production Process

1:Forging & Casting

Electric Arc Furnace

It’s easier and accuracy to control the inner termperature of furnace, so it can improve the purity of steel.It can control the quality of steel from the material. We can casting 1500-50000kgs /PCS

State-owned steel ingot. Maximum 13000 tons oil press

The power of state-owned steel ingot is more pure precision.

The large oil press can much improve the mechanical properties.

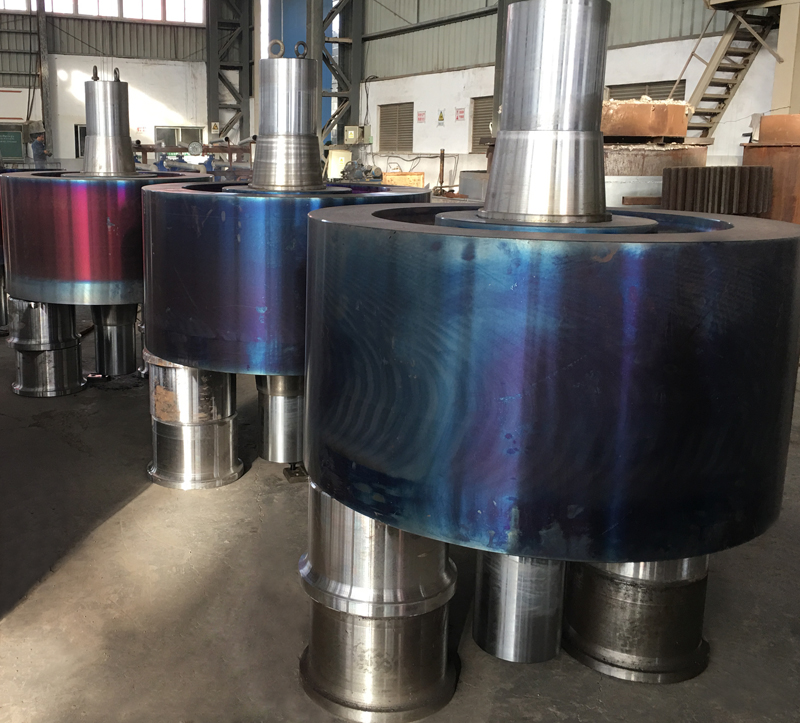

2. Rough machining

φ0.5-8 meters vertical lathe, more than 20 years working experience skillful workers

Large horizontal lathe, more than 20 years working experience skillful workers

3. UT

All our products will do Ultrasonic Test, that’s much difference than other factory.Ultrasonic test can detect whether there are excessive defects inside the product, which can better ensure product quality.

4. QT

Advantage of our heat treatment

a. Professional, specific furnace, single-minded

b. Well-type electric furnace,keep the temperature uniformity within ±1℃

c. Small deformation,little oxide layer,reduce material cost

d. Different materials can be cooled at the best speed

e. Large capacity, completed variety of quenching medium: oil,water,salt water,sythetic quenching medium

5. Finish maching

CNC Gantry Milling: The accuracy can arrive 0.01mm

6.Inspection

Our quality inspection team checks whether the product conforms to the drawings and customer requirements.

After testing products qualified, we will issue product certificate to customers. (including dimensions report, heat treatment report, UT report, hardness report, etc.)

7. Assembly

8. Packaging & Shipping

After assembly, we treat the products against rust, and then pack and ship them.

The choice of our packaging method is based on the characteristics of the product and the requirements of the customer.

四. FAQ

- What’s your payment terms? –T/T & L/C

- Whether O/A is accepted? –NO

- What trade terms do you often use? –EXW/FOB/CIF

REQUEST A QUOTE

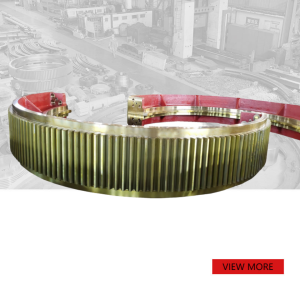

RELATED PRODUCTS

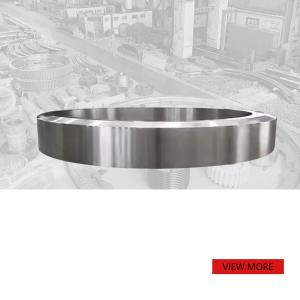

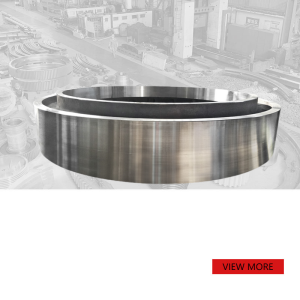

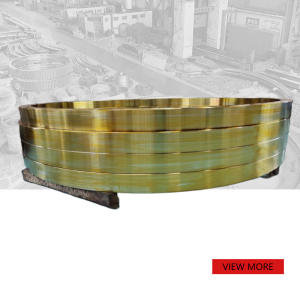

Non-standard customized rotary kiln casting gear ring

Non-standard custom high quality 42CrMo forging ring

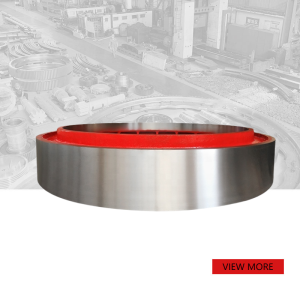

Custom large diameter Casting Rotary Dryer Kiln Tyre

Non-standard alloy steel large diameter casting rotary kiln tyre

Customized Large dimeter rotary dryer 42CrMo forged ring