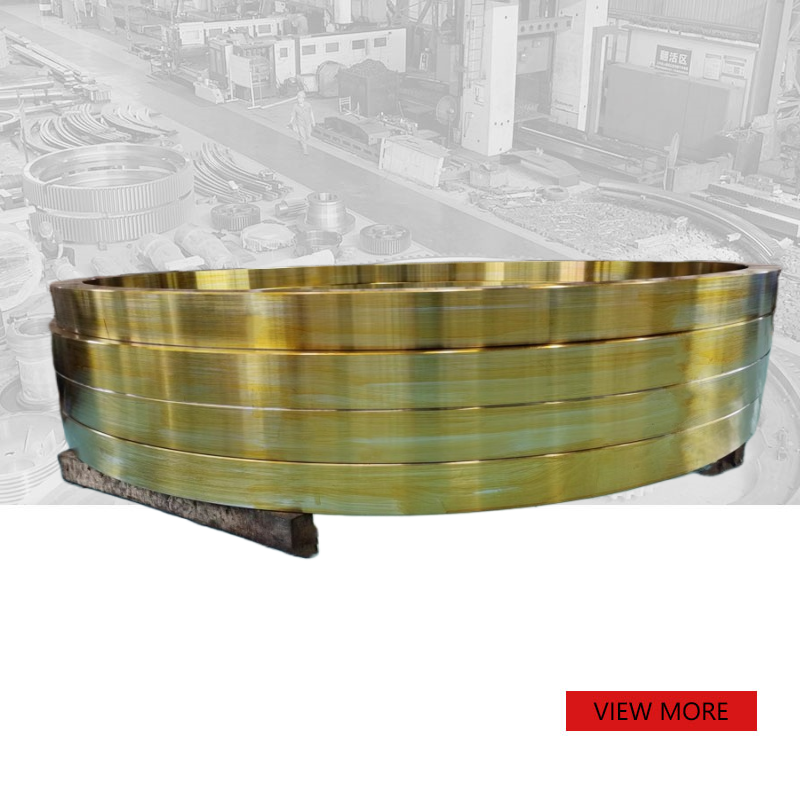

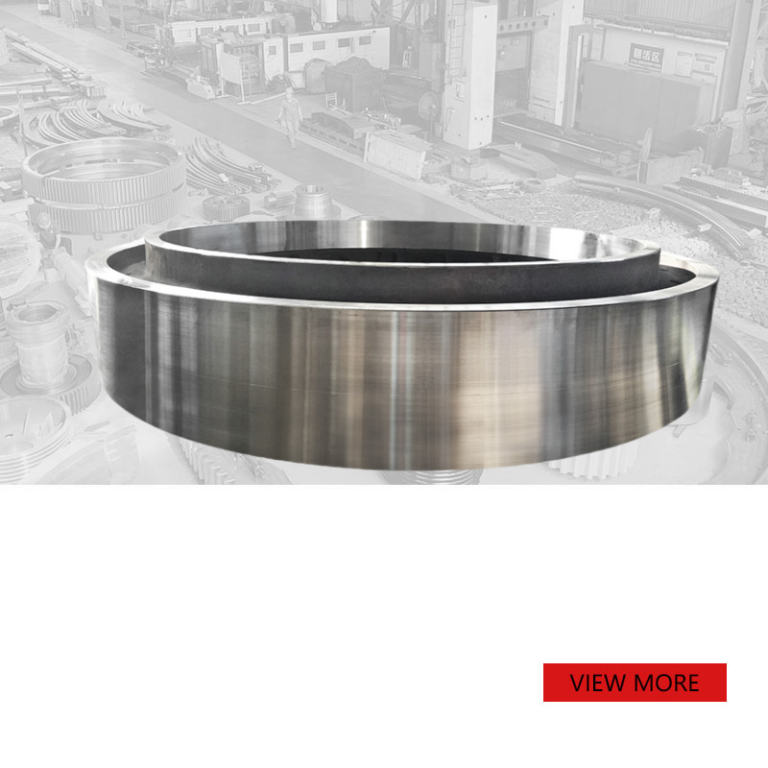

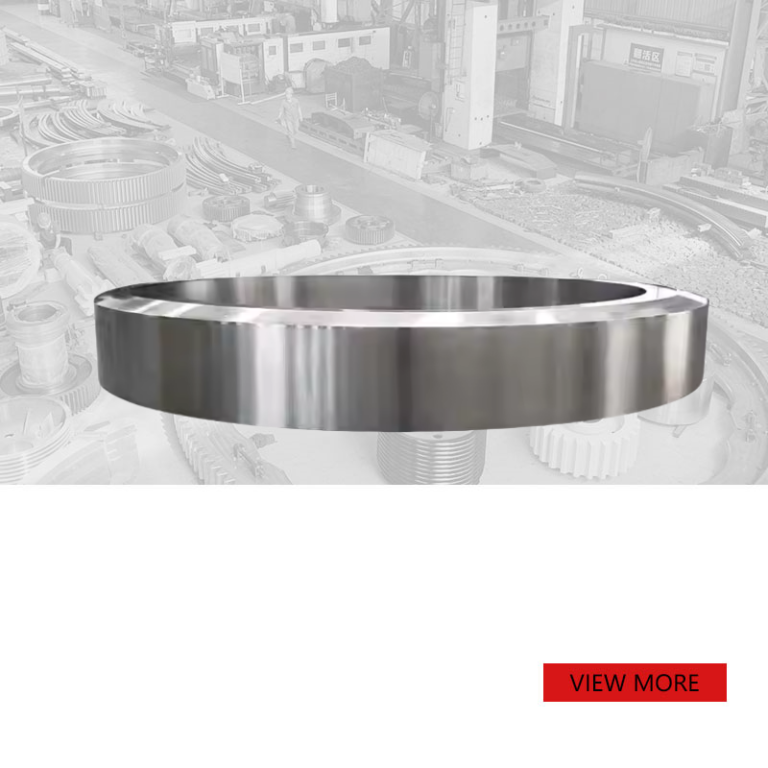

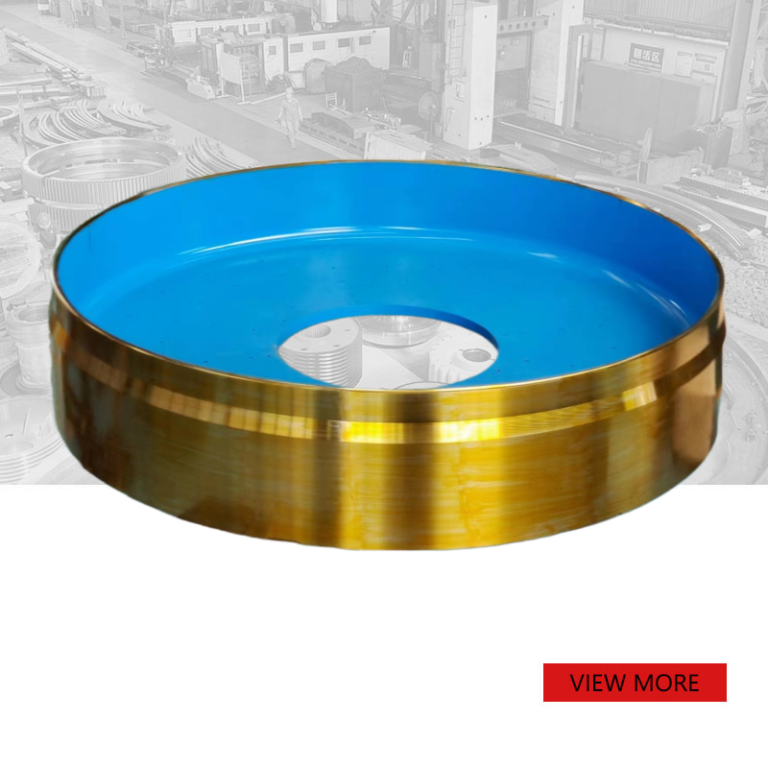

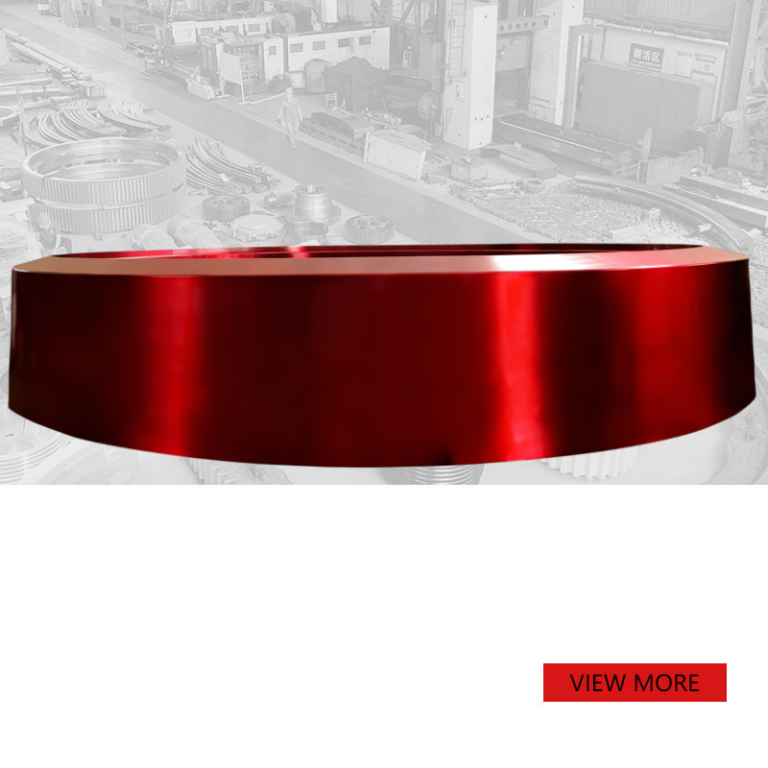

Customized Large dimeter rotary dryer 42CrMo forged ring

PRODUCT PARAMETERS

Description

一.Overview

The forged ring on the dryer is mainly used to support and stabilize the rotating cylinder, ensuring its smooth operation under high temperature and heavy load conditions. The forged ring has high strength and wear resistance, and can withstand continuous mechanical and thermal stress, reducing vibration and noise during operation. In addition, the high-quality forged ring design can also improve the thermal efficiency, helping the material to be more evenly heated, thereby improving the drying effect and production efficiency, and extending the service life of the equipment.

二.Similar usage

1.Cement kiln

2.Ball mill

3.Rotary coller

三.Production process

1.Blank

Blanks of forged rings are usually produced by free forging or die forging. Free forging is to gradually form the heated metal directly under the forging hammer or press; Die forging is the use of a specific mold, so that the metal is formed in a closed mold, ensuring accurate dimensions and uniform internal structure. Both methods increase the density and strength of the material, providing a high-quality starting material for subsequent processing. Heat treatment is often used to enhance its mechanical properties.

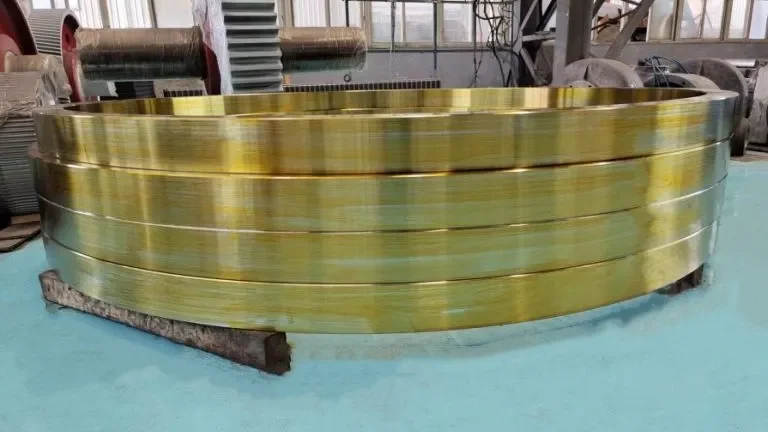

2.Rough machining

Roughing the forged ring removes excess material, forms it initially, and prepares it for finishing, while helping to detect potential defects, ensuring dimensional accuracy and quality, reducing subsequent processing costs, and increasing production efficiency.

3.Heat treatment

The heat treatment of forged ring can enhance its hardness and strength, improve the internal structure of the metal, improve wear resistance and fatigue resistance, ensure long-term stable work under high load and harsh environment, and extend the service life.

4.Finish machining

The precision machining of the forged ring can achieve precise size and surface finish, ensure perfect fit with other components, reduce wear and vibration during operation, improve mechanical properties and service life, and ensure the stability and efficiency of equipment operation.

5.Test

The inspection of the forged ring can ensure that its dimensional accuracy, surface quality and mechanical properties meet the requirements, find potential defects, ensure the safety and reliability of use, and improve the operation efficiency and service life of the equipment.

6.Package

Packing forged rings prevents physical damage during transportation and storage, avoids corrosion and environmental damage, and ensures accuracy and surface quality. Good packaging also facilitates handling and logistics management, reducing the risk of damage and protecting product integrity

四.FAQ

1.Can you produce the casting ring? -Yes

2.What is the largest diameter forged ring you can produce?–16M

3.Is your packing suitable for export? –Yes

Contact us