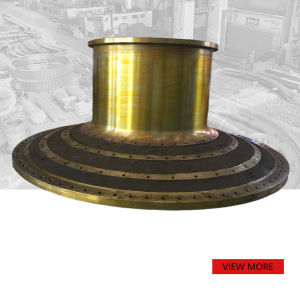

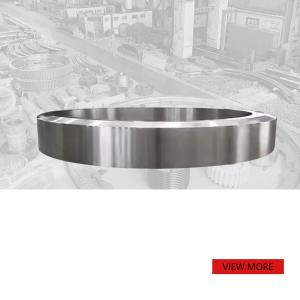

Customized Large Sliding Bearing Casting Seat

PRODUCT PARAMETERS

Description

1. Overview of Bearing Seat

Casting bearing seat is a mechanical part used to support and fix bearings, usually manufactured by casting process. It provides a stable foundation for the rotating shaft and bears axial and radial loads. Casting bearing seat is made of cast iron, steel and other materials, with good wear resistance and strength. Its production process includes mold design, modeling, smelting and pouring, cooling and sanding, cleaning and processing, heat treatment and finishing to ensure that the product achieves the required dimensional accuracy and mechanical properties. Depending on the application, bearing seats have a variety of types and designs to meet specific needs.

2.Application

Our large sliding bearing casting bearing seat block with copper hub is mainly used in large cement plant equipment and metallurgical industry. Such as rotary kiln, ball mill, dryer, etc. We can also produce other large forged or cast gear rings for steel mills, dragline excavators. It can be a complete gear ring or half-segment gear, four segments. Eight segments.

3. Process Flow

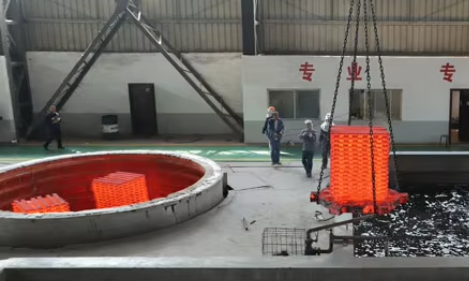

-Casting

Material: Large OEM metallurgical bearing seats/blocks/bearing seats can be produced by forging or casting. Common materials are 35CrMo, 42CrMo, cast g-ray iron, ductile iron, chromium bearing steel GCr15 or other customized materials.

-Pour the molten metal into the pre-prepared mold through the gate, and pay attention to controlling the pouring temperature and speed to avoid defects.

-Heat treatment

According to the needs, the castings are subjected to heat treatment processes such as annealing and normalizing to improve the internal structure and mechanical properties.

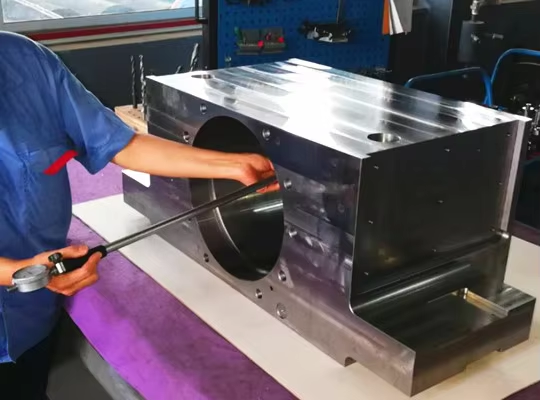

-Finishing

Precision machining such as turning, drilling, boring, etc. is carried out to make the castings reach the final design size and accuracy requirements.

-Inspection

Strict quality inspection of the finished product, including dimensional inspection, appearance inspection, hardness test, etc., and non-destructive inspection is required when necessary to ensure that the product quality meets the standards.

-Packaging

Finally, the finished product is cleaned, packaged, and sent to the customer.

4.FAQs of casting Bearing Seat

-How long is the delivery time? 65-100days

-What are the packaging methods? According to customer requirements, plywood boxes are generally used.

-Do you accept third-party inspection? Yes

REQUEST A QUOTE

RELATED PRODUCTS

Non-standard custom high quality 42CrMo forging ring

42CrMo4 China Big Forging Steel Cement Rotary Kiln Large Support Roller Shaft

Custom Casting Rotary Kiln Tyre

Customized large modulus pinion for rotary kiln

Customized 35# casting Two segment spur girth gear copper mine mill