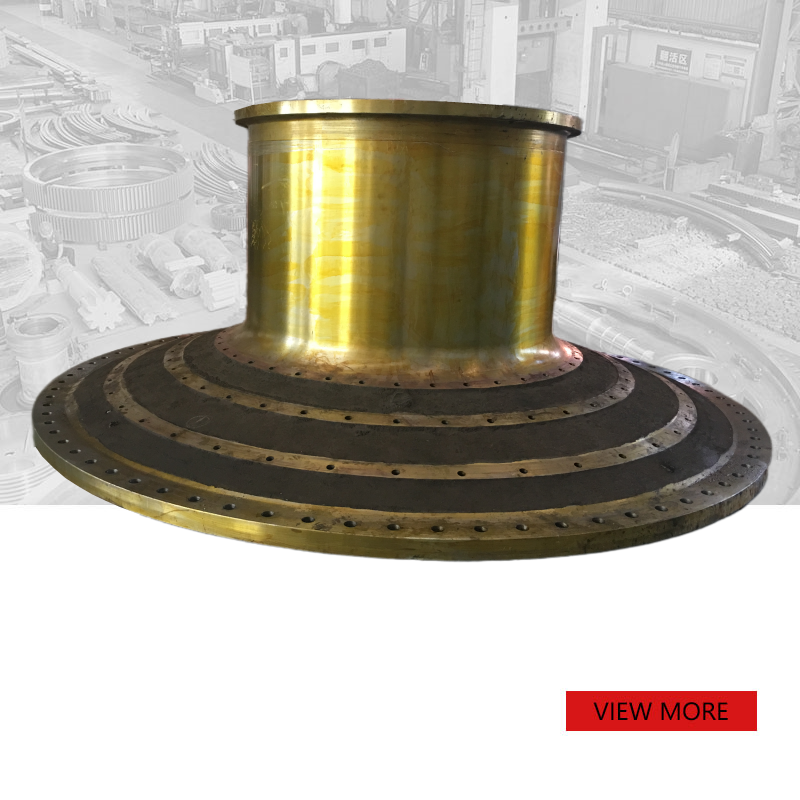

Customized ZG270-500 casting ball mill end cover

PRODUCT PARAMETERS

Description

一. Overview

The ball mill end cover is a sealed structural component located at both ends of the ball mill, which connects the cylinder and the spindle of the ball mill, and plays a role in closing the internal space of the ball mill, transmitting power, entering and leaving materials, assisting adjustment, etc.

二. Usage

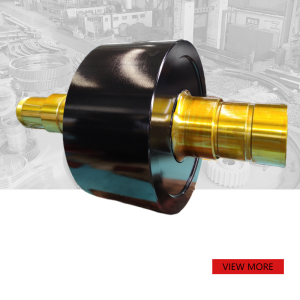

As an important part of grinding equipment such as ball mill and semi-autogenous mill, mill end cover is widely used in many industries and scenarios, such as dressing plant, cement plant, chemical plant, metallurgy and new energy material plant. These devices are mainly used to crush materials to a fine powder or micro-powder state to meet the needs of subsequent processing or applications.

三. Production process

1. Casting

The casting process of ball mill head iis a complex and technically demanding manufacturing process that involves multiple steps and specialized engineering techniques. Such as making models, pouring, cooling, cleaning, inspection, etc.

2. Rough machinig

The roughing of the ball mill head is a very important step in the manufacturing process, which lays the foundation for the subsequent finishing. Such as improving efficiency, releasing stress, surface cleaning, finding defects, adjusting machining allowances and preparing for heat treatment.

3. Heat treatment

Heat treatment of the ball mill head can release more casting stress, prevent deformation, refine grains, control dimensions changes, improve cutting performance, and make it easier to do finish-machining

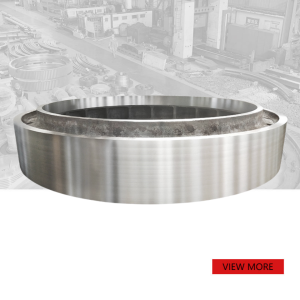

4. Finish-machining

Finish-machining the ball mill head can improve the dimensional accuracy and ensure the accuracy of installation. Optimizing stress distribution to improve wear resistance; Ensure sealing effect. Improve reliability and security,etc.

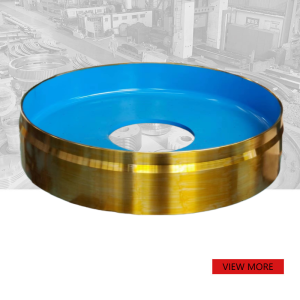

5. Inspection & Painting

The inspection of the ball mill head can ensure dimensional accuracy and assembly requirements, test the integrity of the internal structure, and confirm the physical properties. On the one hand, painting plays a role of beautifying the appearance and easy cleaning, on the other hand, it plays a role of anti-corrosion and anti-rust in the long-term transportation and preservation process.

6. Packing & Shipping

The correct packaging and scientific transportation scheme can not only protect the ball mill head from physical damage, but also improve transportation efficiency and reduce unnecessary costs.

- FAQ

- Whether there is certification and qualification certificate?–We have ISO certificate;

- Whether to accept third-party testing?–Yes

- What kind of payment terms do you have?–T/T & L/C

- What if there is a problem?–24 hours online service