Rolling Mill Coupling

PRODUCT PARAMETERS

Description

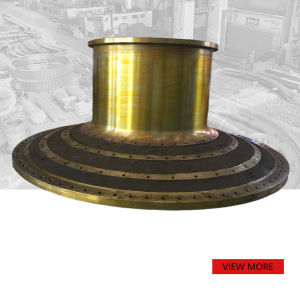

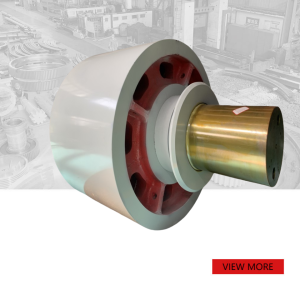

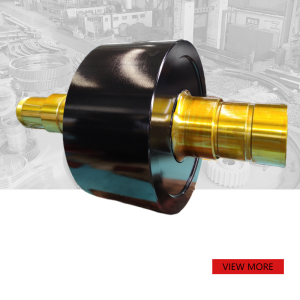

Overview of Rolling Mill Coupling

Rolling mill couplings are specialized mechanical devices designed to connect two shafts for the purpose of transmitting power from one to another in rolling mills. They are crucial components that ensure smooth operation and efficient power transmission in heavy industrial machinery used in the steel manufacturing industry.

Features of Rolling Mill Coupling

- High Load Capacity: Designed to handle high torque and dynamic loads.

- Durability: Made from high-strength materials to withstand harsh operating conditions.

- Flexibility: Accommodates misalignment between shafts, reducing wear and tear.

- Maintenance-Free: Requires minimal maintenance once installed.

- Compact Design: Saves space while providing robust performance.

- Corrosion Resistance: Treated to resist corrosion in humid or corrosive environments.

Specifications/Parameters of Rolling Mill Coupling

- Torque Range: Typically ranges from 10 kNm to 500 kNm.

- Bore Diameter: Available in various sizes to fit different shaft diameters.

- Material: High-strength steel, alloy steel, or stainless steel.

- Operating Temperature: -20°C to +120°C.

- Misalignment Tolerance: Angular up to 2°, parallel up to 1 mm.

Applications of Rolling Mill Coupling

- Steel Mills: Used in rolling mills for hot and cold rolling processes.

- Mining Industry: Connects drives in mining equipment.

- Cement Plants: Transmits power in cement grinding and mixing machines.

- Power Generation: Used in generators and turbines in power plants.

- Conveyor Systems: Ensures reliable power transmission in conveyor belts.

Use Method of Rolling Mill Coupling

- Preparation: Ensure all components are clean and free from debris.

- Installation: Align the shafts and slide the coupling onto the shafts.

- Securing: Tighten the bolts or clamps securely to the specified torque.

- Alignment: Check and adjust for any misalignment.

- Operation: Test the system under load to ensure smooth operation.

Production Process of Rolling Mill Coupling

- Material Selection: Choose high-quality steel or alloy steel.

- Forging: Shape the material through forging to achieve the desired form.

- Machining: Precision machining to ensure accurate dimensions.

- Heat Treatment: Harden and temper the coupling to enhance strength and durability.

- Surface Treatment: Apply coatings or treatments to improve corrosion resistance.

- Assembly: Assemble the components to form the final product.

- Inspection: Conduct quality control checks to ensure compliance with standards.

Company Introduction

Our company, [Company Name], is a leading manufacturer of rolling mill couplings and other industrial components. With over [X] years of experience, we are committed to providing high-quality products and exceptional customer service. Our state-of-the-art facilities and skilled workforce ensure that every product meets the highest standards of performance and reliability.

Package of Rolling Mill Coupling

- Packaging Material: Heavy-duty wooden crates or pallets.

- Protection: Wrapped in plastic and padded with foam to prevent damage during transit.

- Labeling: Clearly labeled with product information, weight, and handling instructions.

Shipment of Rolling Mill Coupling

- Transport Modes: Road, sea, or air freight.

- Delivery Time: Typically 2-4 weeks depending on the destination.

- Tracking: Provide tracking numbers for real-time updates.

- Insurance: Optional insurance available to cover any potential damage during transit.

Payment of Rolling Mill Coupling

- Payment Methods: Wire transfer, credit card, or PayPal.

- Terms: 30% advance payment, 70% upon inspection and before shipment.

- Currency: USD, EUR, or local currency as agreed.

FAQs of Rolling Mill Coupling

Q: What is the maximum torque capacity of your rolling mill couplings?

A: Our rolling mill couplings can handle torque ranging from 10 kNm to 500 kNm, depending on the model.

Q: How do I maintain the coupling to ensure long-term performance?

A: Regularly inspect the coupling for wear, tighten bolts as needed, and keep the surface clean and lubricated.

Q: Can your couplings handle high temperatures?

A: Yes, our couplings are designed to operate in temperatures ranging from -20°C to +120°C.

Q: What is the lead time for custom orders?

A: Custom orders typically have a lead time of 4-6 weeks, depending on the complexity and quantity.

Q: Do you offer installation services?

A: We can provide installation guidance and support, but for professional installation, we recommend contacting a certified technician.

If you have any further questions or need additional information, please feel free to contact us.