Customized ball mill casting grate plate

PRODUCT PARAMETERS

Description

1. Ball mill grate plate overview

Ball mill grate plate is an indispensable component in the grinding process of materials such as ore and cement. It is installed inside the ball mill to protect the ball mill cylinder from wear and improve the grinding efficiency. The grate plate ensures the uniform distribution and efficient discharge of materials during the ball milling process through its unique structural design and material selection, and is one of the key factors affecting the performance of the ball mill.

2. Classification and characteristics of ball mill grate plates

Ball mill grate plates are divided into various types according to different working requirements, such as smooth type, corrugated type, toothed type, etc. Each type of grate plate has its specific design purpose and application occasion to meet the processing requirements of different industries. For example, the corrugated grate plate can increase the residence time of the material, thereby improving the grinding effect; while the toothed grate plate helps to strengthen the impact crushing effect and is suitable for the processing of materials with higher hardness.

3. Installation method and function of ball mill grate plate

When installing the grate plate, you need to follow the instruction manual provided by the manufacturer, which usually includes multiple steps such as pre-assembly, positioning, and fixing. The function of the grate plate is not limited to preventing direct damage to the inner wall of the ball mill, but also effectively adjusting the environment inside the mill, optimizing the contact conditions between the grinding media and the material, and ultimately achieving higher productivity and better product quality.

4. Selection and requirements of ball mill grate plate materials

High-quality grate plate materials are essential to extend the service life of the equipment. Commonly used materials include wear-resistant metals such as high manganese steel and chromium-molybdenum alloy steel. These materials have good wear resistance and toughness and can maintain stable performance in harsh working environments. In addition, according to the specific use, other special alloys or composite materials can also be selected to enhance the durability of the grate plate.

| Parameter | Specification |

| Material | High manganese steel/chromium molybdenum alloy steel |

| Sizes | are customized according to customer requirements |

| Weight | depends on size |

5. Application scenarios, common problems and maintenance of ball mill grate plates

Ball mill grate plates are widely used in mining, building materials, chemical industry and other fields. Common problems include excessive wear, crack formation, etc., which require regular inspection and maintenance. In order to ensure the best condition of the grate plate, the user should establish a standardized maintenance system, including cleaning, lubrication and timely replacement of damaged parts.

- The production process of ball mill grate plate from raw material preparation to finished product packaging, each step is strictly implemented in accordance with quality control standards. The following is part of the process diagram:

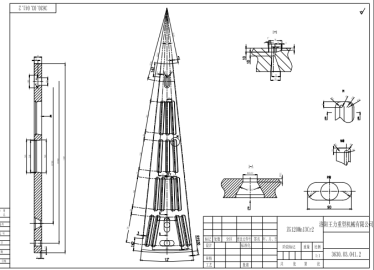

Design and drawing:

– Design the grate plate structure according to the specific requirements and working conditions of the ball mill, and draw detailed drawings, including size, shape and installation location.

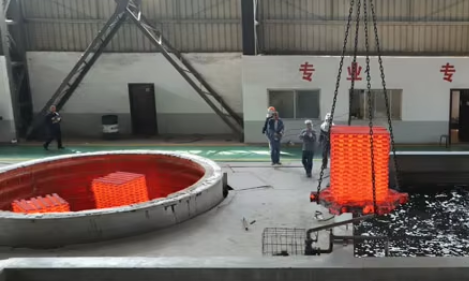

Casting:

– For larger grate plates, casting is usually used; for smaller and complex grate plates, forging technology may be used.

– During the casting process, attention should be paid to controlling factors such as pouring temperature and cooling rate to ensure uniform and dense internal structure.

Heat treatment:

– To improve the mechanical properties (hardness, strength, toughness) of the material, the grate plate needs to undergo heat treatment processes such as quenching + tempering.

– Correct heat treatment parameters can significantly improve the wear resistance and impact resistance of the grate plate.

Quality inspection:

– The finished grate plate must undergo comprehensive quality inspection before leaving the factory, including appearance inspection, dimension measurement, hardness test, and non-destructive testing (such as ultrasonic testing).

– Only products with qualified indicators can be put into use.

Packaging and delivery:

– Finally, the grate plate that has passed all quality inspection links will be properly packaged and ready to be sent to customers.

7.FAQs of casting grate plate

-How long is the delivery time? 45-80 days

-What are the packaging methods? According to customer requirements, plywood boxes are generally used.

-Do you accept third-party inspection? Yes

REQUEST A QUOTE

RELATED PRODUCTS

Custom forging large support roller

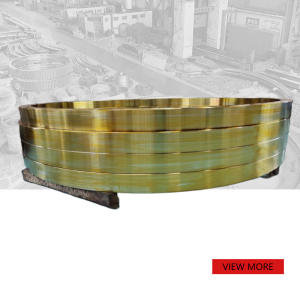

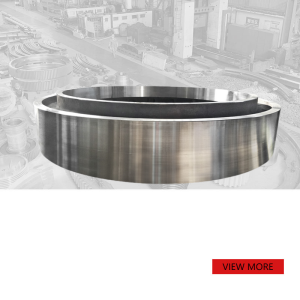

Custom large diameter Casting Rotary Dryer Kiln Tyre

35CrMo Forging Mining large dimeter 12 Segment Arc Tooth

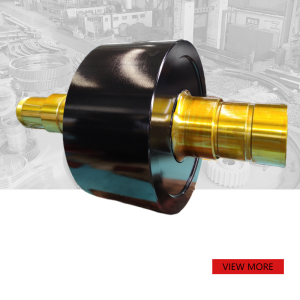

42CrMo4 China Big Forging Steel Cement Rotary Kiln Large Support Roller Shaft

Customized Large Sliding Bearing Casting Seat