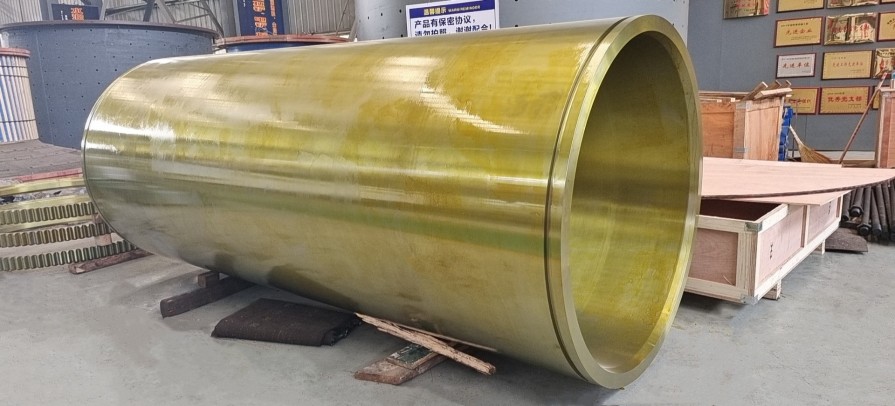

Custom forging large Hydraulic cylinder body

PRODUCT PARAMETERS

Description

一.Overview

In mining equipment, the main role of the hydraulic cylinder is to convert hydraulic energy into mechanical energy as a key component, through the reciprocating movement of the internal piston to achieve linear push and pull, so as to complete operations such as digging, pushing or lifting heavy objects. The cylinder must withstand high pressure to ensure the sealing and stability of the system and prevent the leakage of hydraulic oil. In addition, it must have sufficient strength and rigidity to withstand extreme working conditions, such as high loads, shock and corrosive environments, to ensure that mine equipment can operate safely and efficiently. High quality cylinder design and manufacturing is essential to extend the service life of equipment and improve work efficiency.

二.Features

1. High strength and wear resistance

2. Good sealing performance

3. Corrosion resistance

4. High precision machining

5. Design for extreme conditions

三.Prodcution process

1.Forging

The hydraulic cylinder in mining equipment uses forgings, mainly because forging can enhance the strength and toughness of the material, making it more able to withstand high pressure and impact loads. The internal organization of the forgings is tight, reducing the possibility of defects and improving reliability and durability. In addition, the forging process can optimize the material structure, improve the fatigue resistance of the hydraulic cylinder, ensure long-term stable operation under harsh conditions, and reduce the risk of failure.

2.Rough machining

Rough machining of the hydraulic cylinder is mainly to quickly remove excess material, make the workpiece close to the design size and shape, and prepare for subsequent finishing. This process helps reduce the effort and cost of finishing, while also revealing potential internal defects and ensuring material quality. Roughing also releases the internal stress generated during forging, reducing the risk of deformation in later use

3.Heat treatment

The forging hydraulic cylinder is heat treated to improve its mechanical properties. Heat treatment can enhance the hardness and strength of the material, while ensuring sufficient toughness and improving the resistance to fatigue and impact. This process helps eliminate internal stress and reduces the risk of deformation and cracking during use, thereby extending service life. In addition, proper heat treatment can also improve the processing performance of the material, prepare for subsequent finishing, and ensure the stable and reliable operation of the hydraulic cylinder under high load conditions.

4.Finish machining

Hydraulic cylinders are finished to achieve strict dimensional accuracy and surface finish requirements to ensure their performance and reliability. Finishing can correct the errors of the previous process, improve the fitting accuracy, and reduce the friction and energy loss during operation. In addition, high-quality surface treatment can enhance corrosion resistance and extend service life. Finally, the finishing ensures the stability and durability of the hydraulic cylinder under high load and extreme working conditions, and supports the safe and efficient operation of mining equipment.

5.Rust resistant treatment & Packaging

. Anti-rust treatment can effectively prevent corrosion caused by moisture and salt spray during transportation and storage, and keep the parts in good condition. Suitable packaging not only provides physical protection to avoid collision damage, but also plays a role in moisture-proof and dust-proof. This ensures that the product arrives at its destination in perfect condition, increasing customer satisfaction. In addition, good packaging is easy to handle and identify, improve logistics efficiency.

四.FAQ

- May i know can you accept the third party test? –Yes

- May i know what kind of paytment terms do you have? –T/T & L/C

- May I know if you can arrange railway transportation? –Yes

- Can you provide the mechanical performance report? –Yes

REQUEST A QUOTE

RELATED PRODUCTS

Custom Forging Large Roller Shell High Quality Briquetting Machine Roll Shell Dimpled Roller Shell

Mining machinery bronze & alloy steel Worm & Worm gear

Custom eccentric shaft with bearing seat

Non-standard alloy steel large diameter Casting wheel

Customized High-chromium Alloy Steel Large Cast Crusher Hammer