Customized High-chromium Alloy Steel Large Cast Crusher Hammer

PRODUCT PARAMETERS

Description

1. Overview of Crusher Hammer

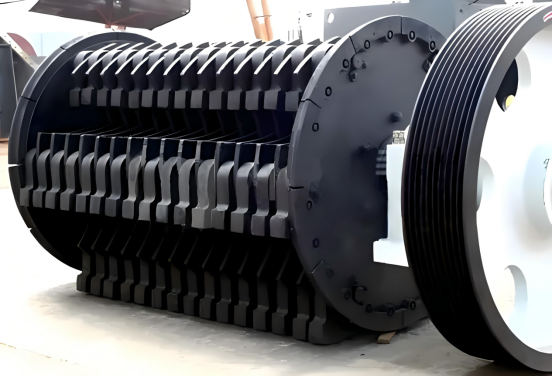

The high-chromium alloy steel large cast crusher hammer is a wear-resistant part designed for extreme working conditions. It is widely used in mining, cement, building materials and other industries to crush materials with higher hardness. This hammer is made of advanced casting technology and high-quality high-chromium alloy materials, which ensures its excellent wear resistance and long life, effectively reducing maintenance costs and improving production efficiency.

2. Classification and characteristics of crusher hammers

Crusher hammers are mainly divided into several types, including ordinary cast iron hammers, composite hammers and high-chromium alloy hammers. Among them, high-chromium alloy hammers are known for their excellent wear resistance and can withstand high-intensity impacts without being easily damaged. It is characterized by high hardness, good toughness and wear resistance, and is particularly suitable for handling hard and corrosive materials, thereby extending the service life of the equipment and reducing downtime.

3. Application scenarios, common problems and maintenance of crusher hammers

High chromium alloy steel cast crusher hammers are suitable for various harsh working environments, such as mining, construction waste recycling and other fields. Although the product has extremely high wear resistance, it is still necessary to prevent excessive wear in actual use. It is recommended that users formulate a reasonable maintenance plan according to the specific situation, including regular cleaning, lubrication and replacement of damaged parts. This not only prolongs the service life of the hammer, but also ensures the safe and stable operation of the entire system.

Crusher hammer parameter specification table

| Material | High chromium alloy steel (Cr content ≥ 20%) |

| Size range | Customized production to meet the needs of different models |

| Weight | Customized according to customer requirements |

| Hardness | HRC50-55 |

| Tensile strength | ≥1100MPa |

4. production process

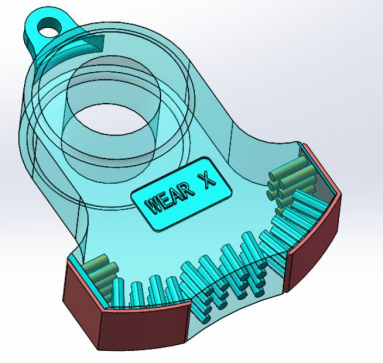

-Hammer head design

We can produce large mechanical parts according to customer’s drawings. According to working conditions and customer’s requirements and mapping, etc., wear-resistant alloy rods can be embedded according to customer’s requirements.

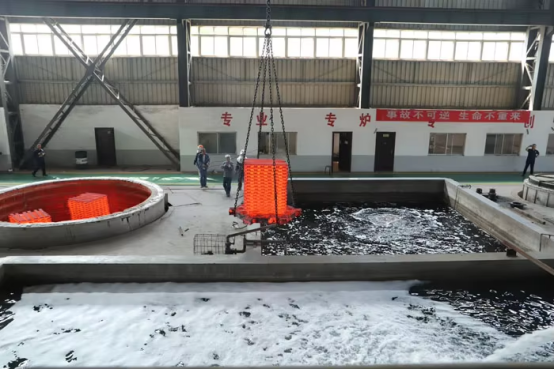

-Casting

In order to prevent casting defects caused by sudden temperature change during pouring, the mold usually needs to be preheated

-Heat treatment

In order to improve wear resistance and toughness, castings are usually subjected to corresponding heat treatment.

-Surface cleaning and quality inspection

Check the quality of castings to ensure that they meet design requirements and technical standards.

-Packaging and delivery

Our packaging materials are environmentally friendly cartons or wooden pallets, which are sustainable and recyclable, aiming to minimize the impact on the environment. With more than 15 years of export experience,

Advantage of Wangli company’s products

1.40+ years experiences focus on metal research and mining machinery spare parts.

2.Three international key projects, such as Segment girth gear used in the Suez Canal in Egypt

3. Besides five workshops, 100+ sets of equipment, capacity of integrating equipment resources from 300+ enterprises (suppliers)

REQUEST A QUOTE

RELATED PRODUCTS

Mining Machinery parts Casting Jaw Crusher Jaw Plates

Custom eccentric shaft with bearing seat

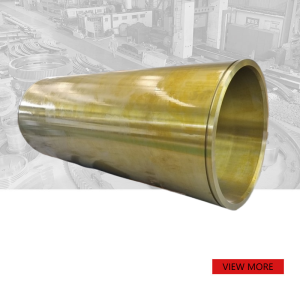

Custom Forging Large Roller Shell High Quality Briquetting Machine Roll Shell Dimpled Roller Shell

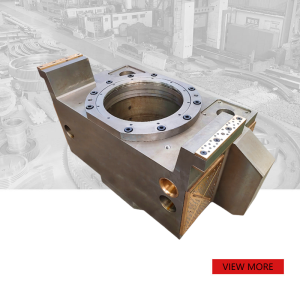

Non-standard alloy steel large diameter casting Bearing seat

Custom forging large Hydraulic cylinder body