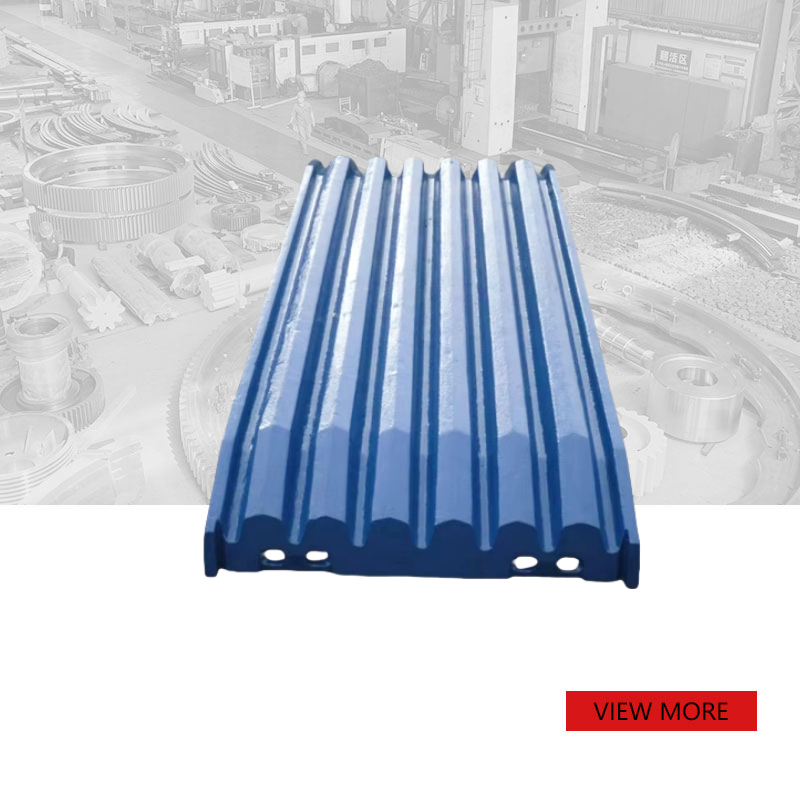

Mining Machinery parts Casting Jaw Crusher Jaw Plates

PRODUCT PARAMETERS

Description

1.Overview of Jaw Crusher Jaw Plates

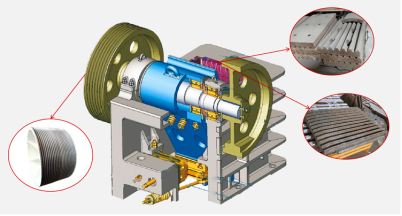

Jaw crusher is a common primary crushing equipment in mining, building materials and cement industries, and jaw plates (Jaw Plates) as its key components are directly involved in the crushing of materials. High-quality jaw plates can not only ensure efficient crushing operations, but also effectively extend the service life of the equipment and reduce maintenance costs. They are usually made of highly wear-resistant materials to cope with the strong impact of hard rocks and ores.

2. Classification and characteristics of jaw crusher Jaw Plates

Jaw plates are mainly divided into fixed jaw plates and movable jaw plates. The fixed jaw plate is installed on one side of the crushing chamber and remains stationary; the movable jaw plate is connected to the connecting rod to achieve extrusion and crushing of the material through reciprocating motion. These jaw plates have high wear resistance, impact resistance and good self-cleaning ability, ensuring long-term stable working performance and low operating costs.

3. Selection and requirements of jaw plate materials for jaw crusher

When selecting jaw plate materials, focus on their hardness, toughness and wear resistance. Common materials include manganese steel, chromium-molybdenum alloy, etc., which can provide excellent wear resistance while maintaining sufficient strength. In addition, in order to meet the needs of different working conditions, manufacturers will also adjust the alloy composition ratio according to actual conditions to optimize performance.

Jaw Plates Specifications

| Material | High Manganese Steel Mn13Cr2 etc. |

| Size Range | Customized According to Specific Models |

| Hardness | HRC 50-60 |

| Standards | ASTM, DIN, EN, GOST, JIS, etc. |

| Structure | Casting |

4. Jaw Plates Production Process

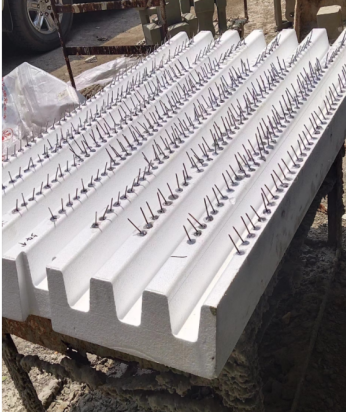

-Mold Design

Based on the shape and size of the jaw plate, determine whether to use an integral or split mold structure. For complex jaw plate shapes, it may be necessary to use a combination of multiple pieces to simplify manufacturing difficulty.

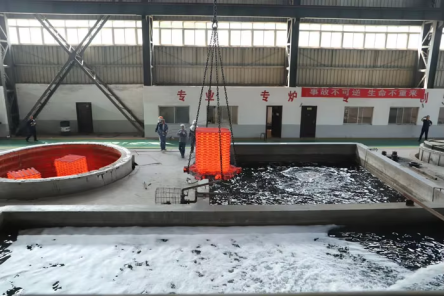

-Casting

The molten metal will be poured into the mold through lost foam casting, sand casting and other processes to form the initial shape of the jaw casting.

-Heat treatment

In order to improve the hardness and wear resistance of the jaw plate, the casting needs to undergo a series of heat treatment processes, such as quenching and tempering.

-Packaging and Delivery

We attach great importance to environmental protection and use sustainable and recyclable materials for packaging to ensure that the impact on the environment is minimized.

5. FAQs of Jaw Plates

-How long is the delivery time? 45-80 days

-What are the packaging methods?

According to customer requirements, plywood boxes are generally used.

-Do you accept third-party inspection? Yes

REQUEST A QUOTE

RELATED PRODUCTS

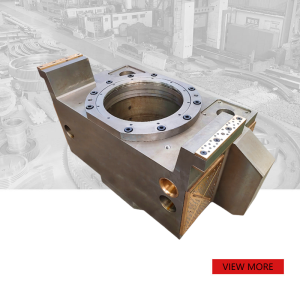

Non-standard alloy steel large diameter casting Bearing seat

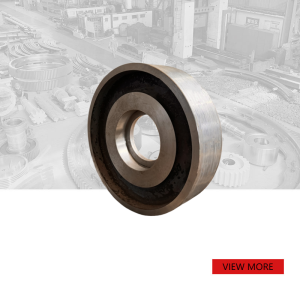

Non-standard alloy steel large diameter Casting wheel

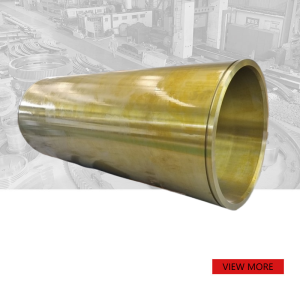

Custom forging large Hydraulic cylinder body

Custom eccentric shaft with bearing seat

Mining machinery bronze & alloy steel Worm & Worm gear