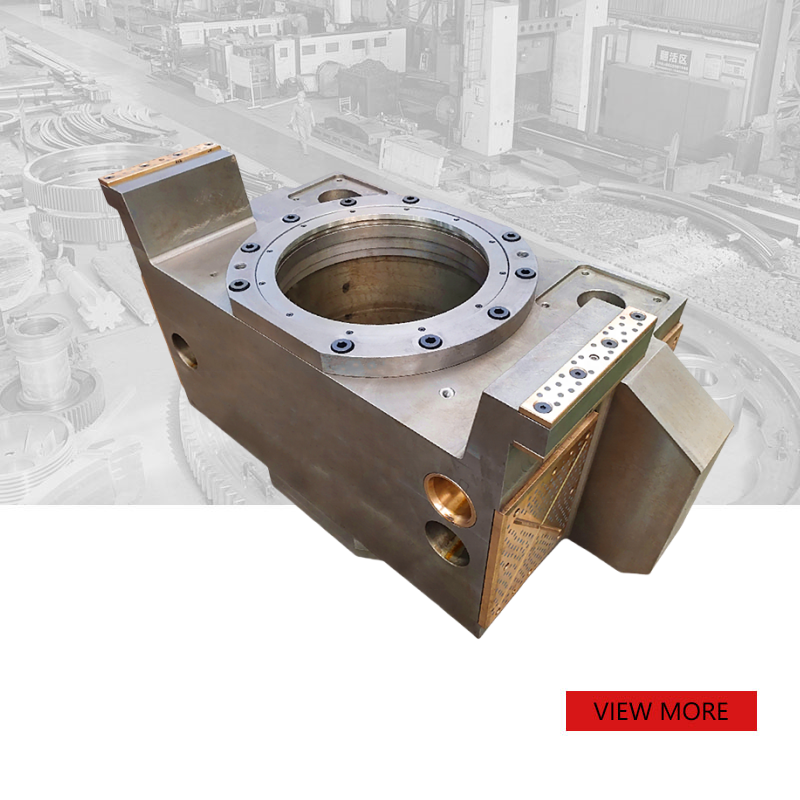

Non-standard alloy steel large diameter casting Bearing seat

PRODUCT PARAMETERS

Description

Overview of Bearing Seat

The cast bearing seat is a component made by the casting process for supporting and positioning the rotating shaft and its bearings. It is usually made of cast iron or cast steel and has high rigidity and stability. The casting process includes mold design, metal melting, casting molding and subsequent treatment. Widely used in mechanical transmission systems to ensure smooth operation and extend equipment life.

| Q | A | Q | A |

| Product name | Bearing seat | Delivery time | 45-60 days |

| Material | Cast Iron | Defect Control | UT, MT |

| Process | Casting +CNC machining+HT | Color | Custom |

| outer diameter | According to the drawings | weight (kg) | 1660 |

| Heat Treatment | Quenching & Tempering | Certificate | ISO9001 |

Production process of Bearing seat

Casting

The blank process of casting a bearing seat involves: designing a sand or metal mold, melting the appropriate alloy material, pouring molten metal into the mold, cooling and stripping, cleaning the surface of the casting, removing the spout, and conducting a preliminary quality check to ensure that there are no apparent defects.

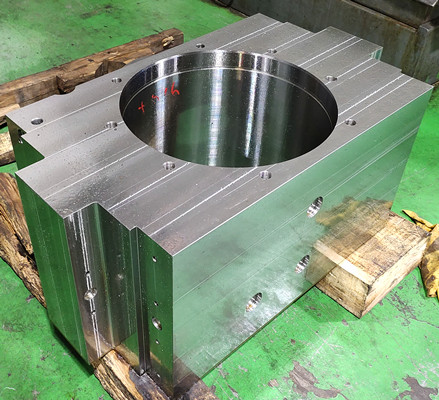

Rough Machining

The roughing process of the casting bearing seat involves: first of all, the initial cleaning of the casting, the removal of the pouring system and burrs; Then by sawing to determine the rough outline; The basic shape and positioning datum are then machined using a lathe or milling machine to ensure the accuracy of subsequent finishing.

Heat treatment

The heat treatment process of the cast bearing seat includes: preheating to reduce the temperature difference stress, followed by quenching and hardening treatment, followed by high temperature tempering to optimize toughness and strength, and finally cooling to room temperature, the entire process is strictly controlled temperature and time to ensure that the material performance is up to standard.

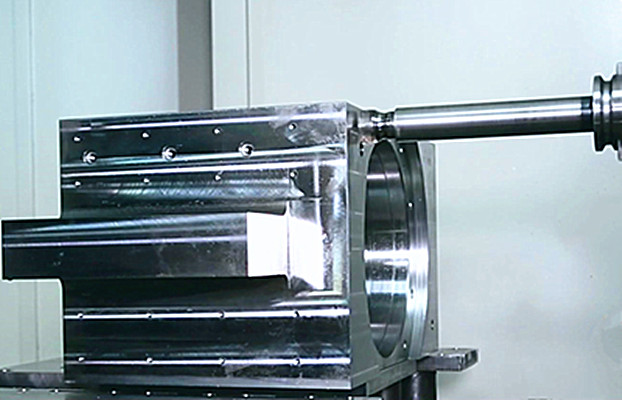

Finishing

The finishing process of the cast bearing seat includes: high-precision turning, milling and boring on CNC machine tools or special equipment to ensure the dimensional accuracy and surface roughness are up to standard; Finally, a comprehensive quality inspection is carried out through the testing instrument to ensure the assembly performance and operation reliability.

Package of Bearing block

Cleaning treatment to remove surface impurities, anti-rust treatment to prevent oxidation, the selection of appropriate packaging materials such as wooden boxes or cartons, and add anti-shock cushion protection, and finally identify product information and handling precautions to ensure transportation safety.

FAQs of Bearing seat

1.What is the accuracy grade you can achieve? –6-8

2.What kind of payment terms do you have? –T/T & L/C

3.Are you subject to third-party testing?-Yes

4. What’s your ship method?– By sea. By rail. By air.

REQUEST A QUOTE

RELATED PRODUCTS

Mining machinery bronze & alloy steel Worm & Worm gear

Customized High-chromium Alloy Steel Large Cast Crusher Hammer

Non-standard alloy steel large diameter Casting wheel

Custom Forging Large Roller Shell High Quality Briquetting Machine Roll Shell Dimpled Roller Shell

Mining Machinery parts Casting Jaw Crusher Jaw Plates