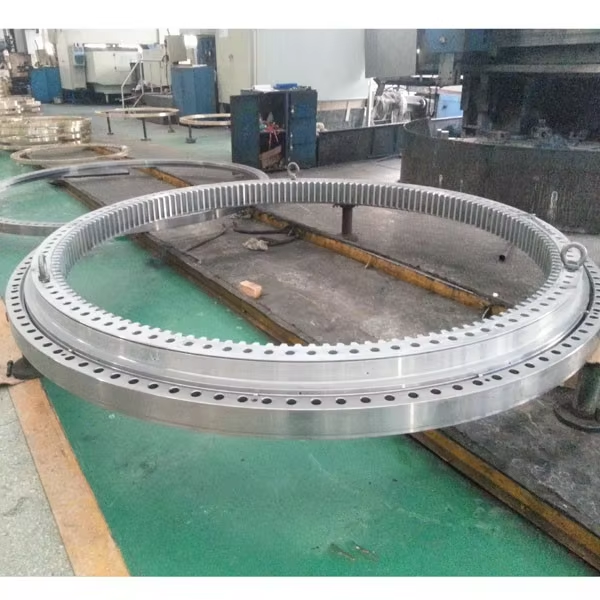

Customized Large Diameter Non-standard Slewing Bearing for Heavy Excavator

PRODUCT PARAMETERS

Description

一. Overview of Slewing Bearing

Slewing bearings, also known as turntable bearings, are large bearings capable of withstanding combined loads, and can simultaneously withstand large axial loads, radial loads, and overturning moments. They are typically used in applications that require medium-speed rotation and precise positioning, such as construction machinery, wind turbines, and marine equipment. Its design allows one part of the machinery to rotate freely relative to another part without the use of traditional shaft and housing assembly.

二.Applications

Our slewing bearings are mainly used as steering gears in wind power generation equipment, large excavators, port hoisting/lifting equipment, steering gears for mining machinery, etc.

三. Process

The production process flow of slewing bearings mainly includes the following steps:

1. Raw material preparation: Select high-quality steel as raw material and perform preliminary processing.

2. Forging: Form the basic shape of the bearing through hot forging or cold forging technology.

3.Heat treatment:

Includes quenching and tempering processes to improve the hardness and wear resistance of the material.

4.Precision machining:

Turning, grinding and other high-precision machining are performed on the inner and outer rings of the bearing to ensure dimensional accuracy.

5.Assembly:

Assemble the components such as the inner ring, outer ring, rolling element and isolation block.

6.Rust prevention and packaging:

Finally, rust prevention treatment is performed and appropriate packaging is used to prevent damage during transportation and storage.

These steps ensure the high quality and reliability of the slewing bearing, enabling it to operate stably in various harsh working environments.

四.FAQs of Slewing Bearing

-How long is the delivery time? 65-100days

-What are the packaging methods?

According to customer requirements, plywood boxes are generally used.

-Do you accept third-party inspection? Yes

REQUEST A QUOTE

RELATED PRODUCTS

Mining Machinery Dragline Excavator Large Steel Casting Rope Wheel

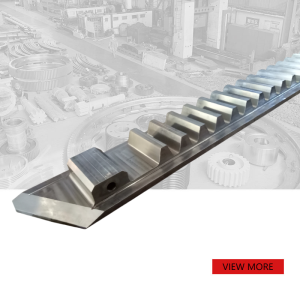

Large mining machinery forging large module helical gear rack

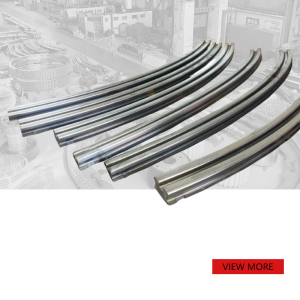

Forging wear-resistant mining machinery spare parts Segment Rail

Mining Large Steel Casting Sheave wheel Custom Rope sheave

Forging rope wheel for Crane