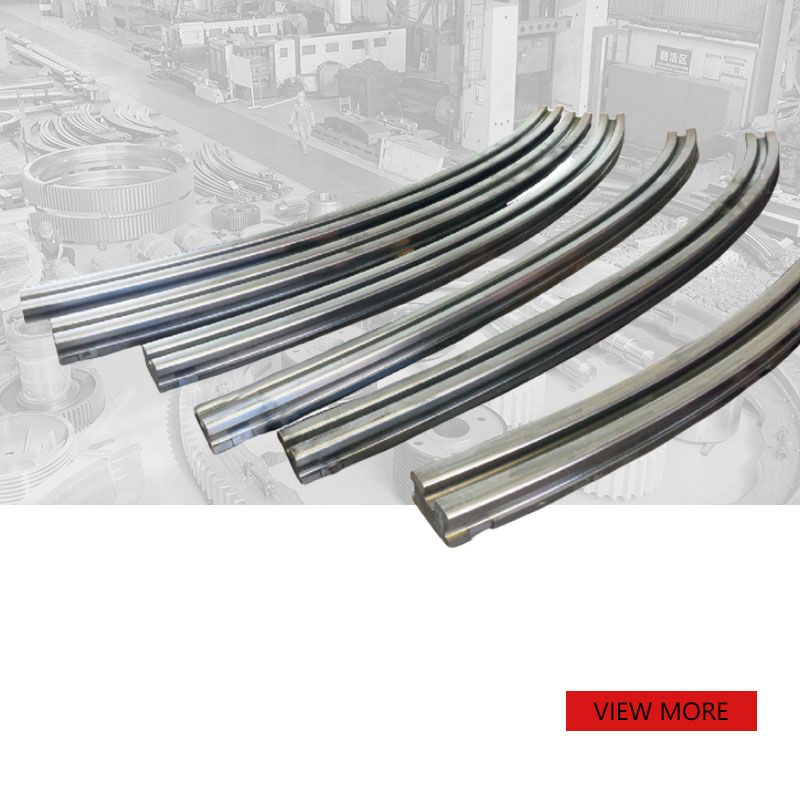

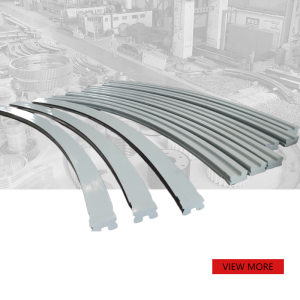

Forging wear-resistant mining machinery spare parts Segment Rail

PRODUCT PARAMETERS

Description

一.Overview

The rails of a large mining excavator mainly bears the role of supporting the weight of the whole machine and guiding the movement of the equipment, ensuring that the excavator can advance or retreat smoothly and accurately on the working surface. It improves the passability and stability of equipment under complex geological conditions and reduces the influence of uneven ground on operation. At the same time, the design of the rail also takes into account the wear resistance to adapt to the harsh working environment of the mine and extend the service life.

二. Production process

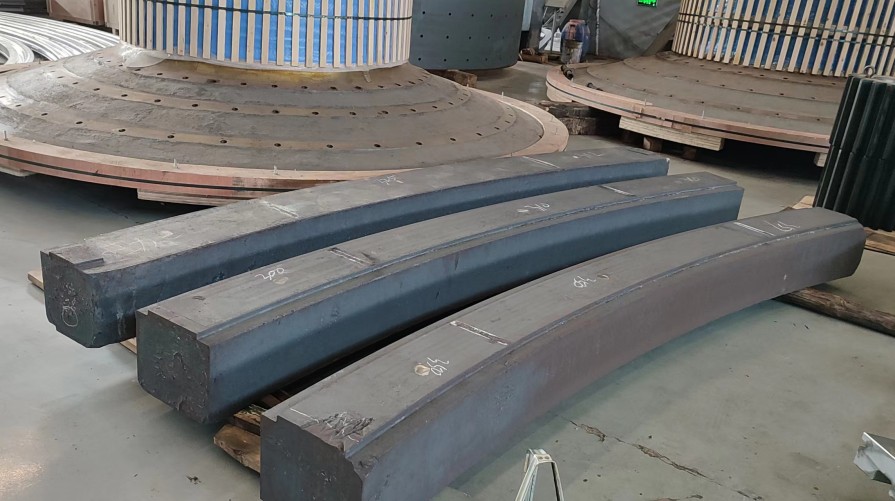

1.Forging

The use of forgings on dragline excavator rail can significantly improve the durability and reliability of the equipment. Forgings refine metal grains through plastic deformation, improve the mechanical properties of the material, so that it has higher strength and fatigue resistance, can work stably under heavy loads and harsh environments for a long time, reduce maintenance needs and extend service life.

2.Rough machining

It is of great significance to rough machinig the rail forging blank of dragline excavator, which can remove the defects such as oxide skin and cracks on the forging surface and ensure the quality of subsequent finish-machining. At the same time, roughing helps to release internal stress, reduce the risk of deformation, improve the dimensional accuracy and shape accuracy of the parts, and lay a solid foundation for the performance and life of the final product. In addition, it can also improve material utilization and processing efficiency.

3.Heat treatment

Heat treatment is a key procedure in the whole production process. Our company be honored with the large mold heat treatment engineering technology center of Luoyang city.Our heat treatment workshop has 6 sets of electric furnace, the deepest one is 9 meters, the largest one diameter is 5.5 meters, the crane 50 tons, and our workshop bearing capacity can reach 100 tons.

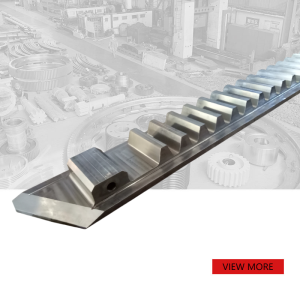

4.Finished machining

Finishing the dragline rail ensures precise dimensions and smooth surface quality, which is essential to improve the smoothness and accuracy of the operation of the equipment. Finishing can reduce wear on the rails surface, extend service life, and reduce maintenance costs. In addition, the high-quality track can effectively improve the excavator’s efficiency and safety, ensuring that it can maintain excellent performance under heavy load operating conditions.

5.Rust resistant treatment & Packaging

Anti-rust treatment of mine equipmentrails can extend service life, enhance safety, reduce maintenance costs, and ensure efficient operation of equipment. Rust prevention can prevent the structural strength of the rail due to rust, avoid expensive maintenance, and improve the overall performance of the equipment to ensure the smooth development of mining operations.

三.Features

1. High strength and wear resistance

2. Adapt to harsh environments

3. Good carrying capacity

4. Precision installation and maintenance requirements

四.FAQ

- What segments can you produce? –According to drawings

- What is the accuracy grade you can achieve? –6-8

- What kind of payment terms do you have? –T/T & L/C

- Whether to provide samples? –No

REQUEST A QUOTE

RELATED PRODUCTS

Custom forged alloy steel large crane hook

Customized Large Diameter Non-standard Slewing Bearing for Heavy Excavator

Dragline excavator custom forging rail

Casting large diameter wear resistant pulley mining dragline

Large mining machinery forging large module helical gear rack