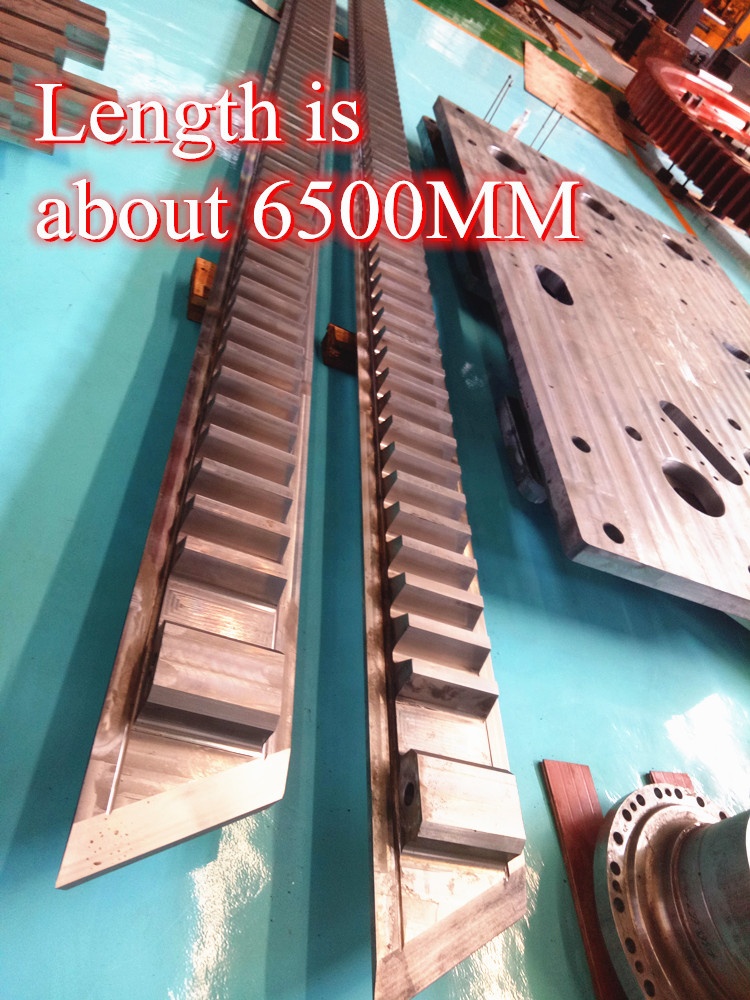

Large mining machinery forging large module helical gear rack

PRODUCT PARAMETERS

Description

一.Overview

The rack of the large mine electric shovel excavator is the key transmission component, which is mainly used to convert the rotating motion of the motor into the linear motion of the mining arm through the gear, so as to realize the accurate expansion and strong operation of the mining arm. The high strength and wear resistance of the rack ensure stable operation under harsh conditions, supporting the efficient implementation of excavation and loading tasks. Its precise transmission performance not only improves operational efficiency, but also enhances operational safety and reliability, which is essential to ensure the smooth operation of the entire mining process.

二.Procution process

1.Foring

The rack of a large mine shovel excavator uses forgings, and its main role includes enhancing the strength and wear resistance of the parts, because the forging process can optimize the grain structure of the metal and improve the mechanical properties of the material. The forging rack can withstand greater loads and impact forces, reducing the risk of deformation and wear in harsh working conditions, thereby ensuring the stability and efficiency of excavation operations, extending the service life of equipment and reducing maintenance costs. In addition, the consistency and reliability of the forgings are higher, which helps to improve the safety of the entire system.

2.Rough machining

Rough machining the rack’s gear can shape the tooth profile in advance and lay the foundation for the subsequent finishing. This step can effectively remove excess material, reduce the workload and cost of finishing, and help to expose possible defects inside the forging, ensuring the quality and strength of the final rack. The coarse teeth can also check the match between the rack design and the actual application, and this process can enable the product to obtain the best mechanical properties during subsequent heat treatment.

3.Heat treatment

Our heat treatment can’t do well without 5 factors. 1. We all use well electric furnace, through radiation heating, the parts can be heated very evenly, it not only can protect the environment, but also can effectively reduce the deformation of the workpiece. As our leader, an engineer who has been engaged in mechanical manufacturing for 42 years said the biggest problem in mechanical manufacturing is deformation, the deformation of the workpiece can be minimized by heating it in the well furnace;2.The quenching medium complete: oil, synthetic quencher, water and salt water. According to different materials and process requirements, we will use different medium for quenching and cooling at the fastest cooling speed allowed for the part, and then tempering to achieve the best mechanical properties;3.Large cooling capacity, there are 450 tons of synthetic quencher and water respectively and we add the cooling circulation system, then the large spare parts can be heat treated;4.Special furnace:this furnace only has this one workpiece. The best process can be customized according to the size of the part our leaders said, our heat treatment likes a taxi, others heat treatment likes a bus;5.Professional: Today’s engineer has been engaged in machinery manufacturing for more than 40 years and has worked in large state-owned enterprises.

4.Finish machining

The finishing of the forging rack of the large mine electric shovel excavator is mainly to achieve the exact size and surface finish required by the design. Finishing can improve the accuracy of the rack, ensure the perfect mesh between it and the gear, reduce the noise and wear during operation, thus extending the service life. In addition, the finishing can eliminate the surface defects left by rough machining, further enhance the mechanical properties and fatigue strength of the rack, ensure the stability and reliability under high load and harsh working conditions, and ultimately improve the efficiency and safety of the entire equipment.

5.Test

a. Dimensional accuracy detection: ensure that the dimensions of the rack (such as tooth shape, pitch, thickness, etc.) meet the requirements of the design drawings.

b. Surface quality inspection: Evaluate whether there are cracks, scratches or other defects on the surface of the rack

c. Hardness test: This is essential to ensure the wear resistance and pressure resistance of the rack under high load conditions.

d. Flaw detection: Use ultrasonic detection to detect whether there are hidden cracks or defects inside the rack to avoid potential safety hazards.

6. Package

The export packaging of the rack of a large mine shovel excavator can protect it from damage during long-distance transportation, prevent corrosion caused by moisture, salt spray, etc., ensure that the accuracy and surface quality of the rack are not affected, and facilitate loading and unloading operations, helping to improve customer satisfaction and maintain the international reputation of the manufacturer.

三.FAQ

1.What module of gear rack you can produce?–8-120

2.Can you do the MT? –Yes

3.Do you accept the third party inspect? –Yes

4.Can you ship by sea?–Yes, we can ship by sea, by ra

REQUEST A QUOTE

RELATED PRODUCTS

Casting large diameter wear resistant pulley mining dragline

Mining Machinery Dragline Excavator Large Steel Casting Rope Wheel

Forging rope wheel for Crane

Custom forging gear rack for Dragline excavator

Forging wear-resistant mining machinery spare parts Segment Rail