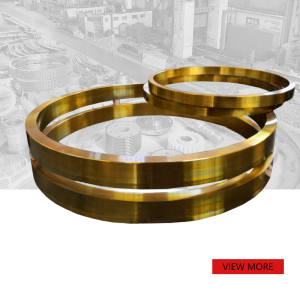

35CrMo Forging Mining large dimeter 12 Segment Arc Tooth

PRODUCT PARAMETERS

Description

一.Overview

| Module | 8-120 | |

| Structure | Forging/Casting/Forging+Welding | |

| Material | Carbon steel, Alloy steel | |

| Accuracy | 6-8 | |

| Tooth profile | Spur gear/Helical gear |

Forged segment arc tooth are widely used in a variety of heavy machinery and precision equipment, such as construction machinery, mining machinery, shipbuilding and wind power generation. As a key transmission component, these gear rings are mainly used to achieve torque transmission and speed conversion between mechanical systems to ensure the stability and efficiency of equipment operation. Because the forging process can improve the mechanical properties of the gear ring, so that it has higher strength and wear resistance, it is particularly important in high loads and harsh working environments.

二. Features

1. High strength and wear resistance

2. Excellent toughness

3. Precise dimensional accuracy

4. Good surface quality

三. Production process

1.Forging

The forged blank makes the metal material more dense through plastic deformation, eliminating internal defects such as shrinkage holes, bubbles, etc., thus improving the mechanical properties of the material, such as strength, toughness and wear resistance. The grain structure is optimized to enhance the overall performance and reliability of the parts. In addition, the size of the forged blank is accurate and the surface quality is good, which can reduce the subsequent processing steps, improve production efficiency and reduce costs. These advantages make forged blanks ideal for the manufacture of high-performance critical components.

2.Rough machining

The roughing of the forged gear ring has many important meanings: first, it can quickly remove a lot of excess material, so that the workpiece is close to the final shape and size; Secondly, reduce the margin and time of subsequent finishing, effectively reduce production costs; In addition, possible defects inside the material can be discovered in advance through roughing, so as to deal with them in time to ensure the quality and reliability of the final product. This process is the basis for ensuring the smooth progress of the subsequent processes.

3.Heat treatment

Our heat treatment can’t do well without 5 factors. 1. We all use well electric furnace, through radiation heating, the parts can be heated very evenly, it not only can protect the environment, but also can effectively reduce the deformation of the workpiece. As our leader, an engineer who has been engaged in mechanical manufacturing for 42 years said the biggest problem in mechanical manufacturing is deformation, the deformation of the workpiece can be minimized by heating it in the well furnace;2.The quenching medium complete: oil, synthetic quencher, water and salt water. According to different materials and process requirements, we will use different medium for quenching and cooling at the fastest cooling speed allowed for the part, and then tempering to achieve the best mechanical properties;3.Large cooling capacity, there are 450 tons of synthetic quencher and water respectively and we add the cooling circulation system, then the large spare parts can be heat treated;4.Special furnace:this furnace only has this one workpiece. The best process can be customized according to the size of the part our leaders said, our heat treatment likes a taxi, others heat treatment likes a bus.

- Finished machining

Finished machining the segment girth gear ensure that key dimensions and form and position tolerances are precisely in line with design requirements, increasing transmission efficiency and service life. This process improves tooth surface finish, reduces friction and noise, enhances working stability and reliability, and eliminates minor defects left by roughing, thus ensuring product performance and durability under strict conditions, and ultimately improving the overall operating efficiency of the mechanical device.

- Test

MT of the segment girth gear can effectively detect surface and near-surface cracks and other defects to ensure that there is no hidden danger in product internal quality. The dimensional detection is used to verify the dimensional accuracy of the gear ring to ensure that it meets the design requirements, and the two work together to ensure the performance reliability and assembly applicability of the gear ring, providing protection for subsequent use.

- Package

We’ll pack according to customer’s needs and suitable for exporting.

- FAQ

- Can you produce the casting girth gear? –Yes,we can.

- Can you accept the third party inspect? –Yes

- What’s your payment terms? — T/T & L/C

REQUEST A QUOTE

RELATED PRODUCTS

Casting ZG30# large diameter spur gear conveyor

Custom casting large diameter herringbone gear

Customized main transmission forged steel large diameter spur gear

Customized casting ring gear for Ball mill

Mining machinery bronze & alloy steel Worm & Worm gear