Customized Crusher Large Diameter Spiral Bevel Gear

PRODUCT PARAMETERS

Description

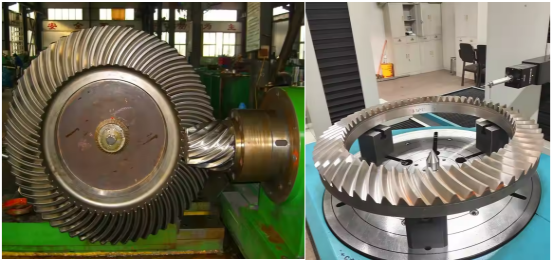

1. Overview of Crusher Spiral Bevel Gear

Crusher spiral bevel gear is a transmission component designed for crushing equipment to achieve efficient transmission of power from the motor to the crushing device. This gear has a special spiral angle and conical structure, which can provide high-efficiency power conversion in a compact space, ensuring stability and reliability during the crushing process. Its precision processing technology and the selection of high-strength materials enable the component to withstand extreme working conditions.

2. Application of Crusher Spiral Bevel Gear

Spiral bevel gears are widely used in the drive systems of large and medium-sized crushers in industries such as mining, metallurgy, and building materials. They are not only suitable for the primary crushing stage, but also play a role in secondary and even tertiary crushing. Through optimized design, these gears can meet the needs of different types of material handling, including efficient crushing operations of hard materials such as hard rock, ore, and concrete.

3. Features of Crusher Spiral Bevel Gear

Spiral bevel gears provide a smooth and quiet operating experience with their unique geometry, reducing vibration and noise levels. Made of high-quality alloy steel, and heat-treated to enhance hardness and wear resistance, thereby extending service life. In addition, the precise tooth surface contact design ensures optimal load distribution, improves energy transmission efficiency and reduces maintenance costs.

4. Crusher spiral bevel gear production process

Production begins with the selection of raw materials, usually alloy steel with good mechanical properties. Next is the forging process to form the basic shape; then rough machining, and then heat treatment steps such as carburizing or quenching to increase the surface hardness. Finally, fine grinding and testing ensure that each gear meets strict tolerance requirements for perfect matching and trouble-free operation. The entire process strictly follows quality control standards to ensure product consistency and reliability.

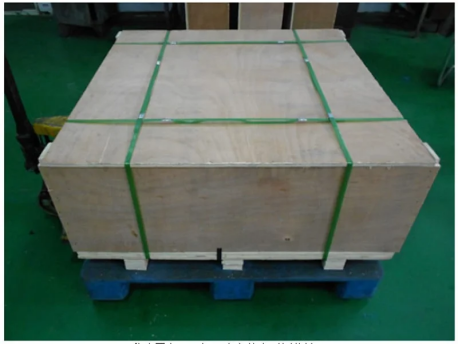

5. Packaging

We strive to improve our packaging solutions and strive to adopt the most reasonable transportation methods and packaging solutions. The lining materials used meet environmental protection standards, have good sustainability and recyclability, and are committed to reducing the impact on the natural environment. Our products and services have won wide recognition and support from domestic and foreign customers.

Advantage of Wangli company’s products

1.40+ years experiences focus on metal research and mining machinery spare parts.

2.Three international key projects, such as Segment girth gear used in the Suez Canal in Egypt

3. Besides five workshops, 100+ sets of equipment, capablity of integrating equipment resources from 300+ enterprises (suppliers)

REQUEST A QUOTE

RELATED PRODUCTS

35CrMo Forging Mining large dimeter 12 Segment Arc Tooth

Spur gear forging high quality large diameter pinion gear

Forging cuatomized 42CrMo large module mining machinery Spur Gear

Casting segment ring gear for rotary kiln

Non-standard customized rotary kiln casting gear ring