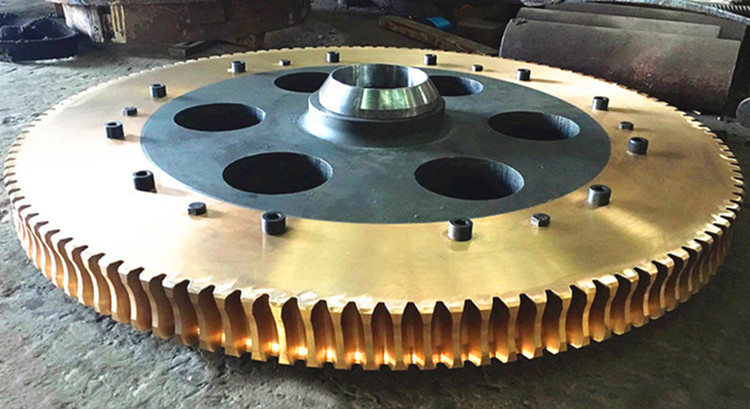

Mining machinery bronze & alloy steel Worm & Worm gear

PRODUCT PARAMETERS

Description

一.Overview

Worm gear and worm in mining equipment are mainly used to achieve efficient and smooth transmission of heavy machinery. They provide a high reduction ratio to control the speed and torque output of large equipment for critical operations such as digging, crushing, and conveying. Its compact design helps to save space, while its good self-locking performance ensures safe and stable operation. In addition, the large size worm gear can also withstand larger loads, reduce energy loss, and improve the durability and reliability of the entire system.

二.Features

1. High load carrying capacity

2. Excellent wear resistance

3. Good self-locking performance

4. Compact design

5. Smooth transmission performance

三. Production process

1.Forging & Casting

Casting of worm gear is usually chosen because it is able to use a better wear resistant material such as bronze, which helps to improve the wear resistance of the worm gear and the smoothness of operation, reducing the need for maintenance. The choice of worm forging is because forging can refine metal grains, enhance the strength and toughness of the material, make it more able to withstand high loads and stresses, and reduce the risk of fracture.

2.Rough machining

Rough machining of worm gear and worm is mainly to quickly remove excess material, close to the final shape and size, and reduce the workload and cost of finishing. This process helps to identify and eliminate internal defects and ensure part quality. Roughing can also release the internal stress of the material, reduce the risk of deformation in subsequent use, and lay a good foundation for subsequent heat treatment and finishing.

3.Heat treatment

The heat treatment of worm gears and gears is designed to optimize their mechanical properties. Heat treatment can significantly improve the hardness and wear resistance of parts, while ensuring sufficient toughness and enhancing fatigue and impact resistance. This process helps eliminate internal stress and reduces the risk of deformation and cracking during use. Proper heat treatment can also improve the machinability of the material, prepare for subsequent finishing, and ensure stable and efficient operation of the equipment.

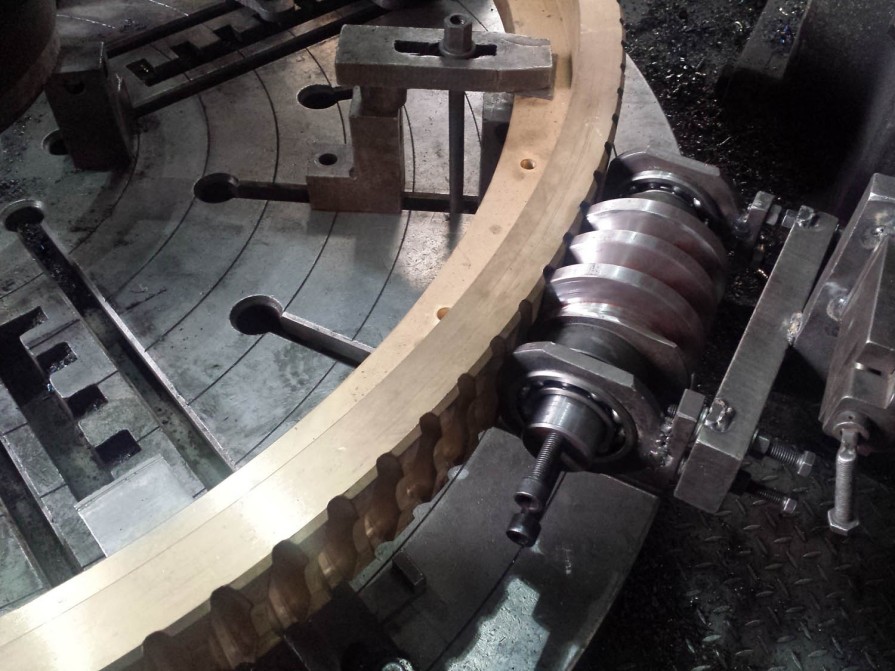

4.Finish machining

The worm gear and worm are refined to achieve strict dimensional accuracy and surface finish requirements to ensure efficient and smooth transmission effects. Finishing can correct the small deformation after heat treatment, improve the fitting accuracy, reduce noise and vibration. In addition, it can also enhance the wear resistance and fatigue resistance of parts, extending the service life. High quality finishing is essential to ensure long-term stable operation of equipment, improve overall mechanical efficiency and reduce maintenance costs.

5.Package

When packing the export worm gear, it is necessary to consider the requirements of moisture-proof, rust-proof, earthquake-proof and easy handling. Usually vacuum packaging or the use of anti-rust oil film to prevent oxidation, while the use of foam, plywood boxes and other materials reinforced to resist vibration and collision during transportation. Good packaging not only protects products from damage, but also facilitates identification and management, ensuring smooth customs clearance and delivery. In addition, the application of environmentally friendly packaging materials has also received increasing attention, both in line with international logistics standards, but also to enhance the corporate image and promote sustainable development.

四.FAQ

1. Problem: Serious wear

– Solution: Choose more wear-resistant materials (such as bronze alloy worm gear) or use surface treatment technology (such as carburizing, nitriding) to improve wear resistance.

2. Problem: insufficient lubrication or failure

– Solution: Optimize the lubrication system design and clean the oil circuit regularly to prevent dust and impurities from mixing into the lubricating oil.

3. Problem: overheating deformation

– Solution: Improve the heat dissipation design, monitor the operating temperature of the equipment, adjust the load in time to avoid long-term overload work.

4. Problem: The self-locking performance fails

– Solutions: accurate calculation of the spiral lift Angle, regular inspection of the status of worm gear, timely repair or replacement of severely worn parts

5. Problem: manufacturing and installation errors

– Solution: Strengthen the quality control in the manufacturing process, and use professional tools and technical guidance during installation to ensure accurate alignment. For key parts, advanced equipment such as laser centering instrument can be considered for auxiliary installation.