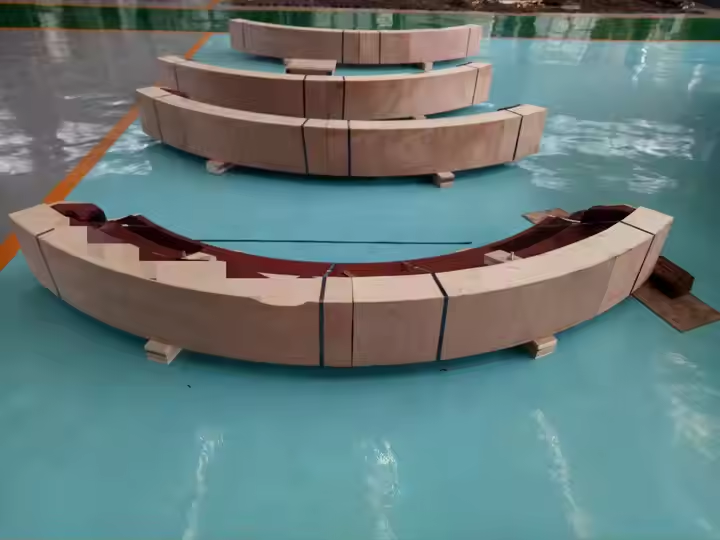

Non-standard customized large diameter 4 large segmented ring gear

PRODUCT PARAMETERS

Description

1 Overview of segmented ring gear

The segmented ring gear is a transmission component specially designed for large mechanical equipment such as rotary kilns, ball mills, etc. It simplifies the installation and maintenance process by dividing the entire ring gear into several segments. Each segment is independently manufactured with high strength and wear resistance, and can withstand large loads and complex working conditions. This design is not only convenient for transportation and assembly, but also only replaces the damaged part when worn or damaged, reducing maintenance costs and extending the service life of the equipment. In addition, the design of the segmented ring gear optimizes the mechanical transmission efficiency and improves the overall performance of the equipment.

Parameter Table

| Material: | Carbon steel, alloy steel |

| Gear module: | 8-200 |

| Structure: | Forging |

| Gear length: | Maximum 10,000 mm |

| Standard: | ASTM DIN, EN GOST JIS, etc. |

| service: | Based on customer drawings |

| Heat treatment: | Q&A |

We can produce large forging,casting and welding gears according to customer’s drawings.According to the working conditions and clients’ request,we also can do gear grinding,surface hardening,cemented and quenching and quenching,etc.

2. Application of segmented ring gear

We can produce large forging,casting and welding gears according to customer’s drawings.According to the working conditions and clients’ request,we also can do gear grinding,surface hardening,cemented and quenching,Nitriding and quenching,etc.

Our large diameter segment large ring gear mainly used for Rotary kiln,Ball Mill,Dryer,etc.

3.Production process

-Machining

Rough turning: Use CNC lathe to perform preliminary turning on the forging to form the basic geometric shape.

– Heat treatment

If the module of the gear or rack is large (above M20), the first CNC milling is performed before heat treatment. According to this way, the QT after the hardness depth of the gear teeth will be deeper, thereby improving the mechanical properties of the gear teeth and extending the service life of the rack.

After rough machining, we perform UT or MT test to ensure that the forged or cast blank has no internal defects.

-Inspection and testing

Dimension detection: Use three-coordinate measuring machine, gear measuring instrument and other equipment to check key size and shape tolerance.

Performance testing: Hardness testing, tensile testing, etc. are carried out as needed to verify the mechanical properties of the material.

– packaging

Finally, clean and rust-proof treatment is carried out, and it is protected with appropriate packaging materials for transportation and storage.

4. Why Choose Us

– 40+ years experiences focus on metal research and mining machinery spare parts.

– Three international key projects, such as Segment girth gear used in the Suez Canal in Egypt

– Besides five workshops, 100+ sets of equipment, capablity of integrating equipment resources from 300+ enterprises (suppliers)

-8 material senior engineers and 40+ patents

REQUEST A QUOTE

RELATED PRODUCTS

Custom casting large diameter herringbone gear

Forging AISI4140 non-standard large Helical gear for ball mill

Customized forging high quality segment ring gear

Customized casting ring gear for Ball mill

Forging high quality Large diameter Bevel gear