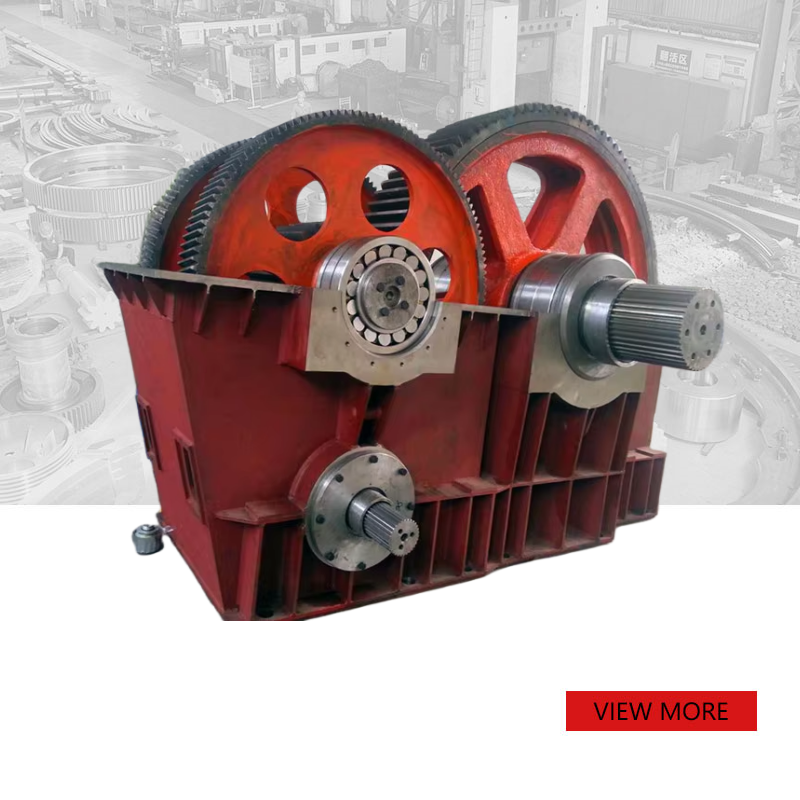

High Quality Reduction Transmission Large Modulus Gear Box

PRODUCT PARAMETERS

Description

1. Overview of Gear Box

This is a non-standard gearbox, which is produced according to drawings or customer requirements. The maximum weight is 50 tons per piece. Large mining excavator gearboxes are widely used. Usually we produce large mining excavator gearboxes according to drawings. At the same time, we can design large mining excavator gearboxes according to customer requirements.

2. Application

Our transmission OEM large gearbox is mainly used as dragline excavator, mill, cement rotary kiln, dryer, etc.

3. Production process

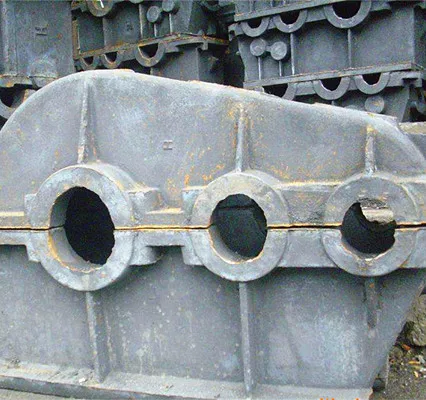

-Casting box

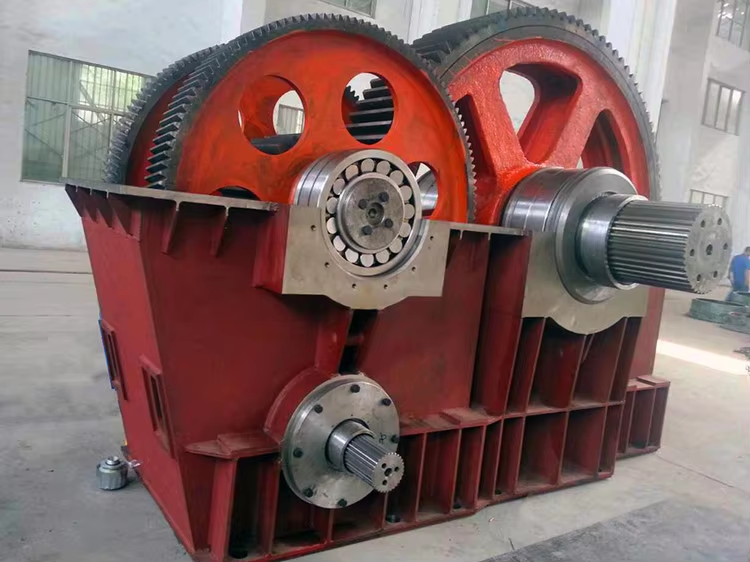

-Assembly

The basic steps of speed reducer assembly include: first, make sure all parts are clean and intact; second, install the bearings of the input and output shafts and ensure they run smoothly; then, assemble the gear assembly, paying attention to the correct meshing of the gears at each level; next, fix the cover of the box, and check and adjust the clearance between the gears; finally, add lubricating oil to the specified amount, complete the assembly and conduct a test run to ensure that everything is normal. Each step must be strictly operated in accordance with technical specifications to ensure assembly quality. This process requires meticulousness and patience to ensure the working efficiency and service life of the speed reducer.

-Inspection

Running test high quality reduction transmission large modulus gearbox

Running test is essential for gearboxes. This can test the accuracy and noise requirements. All our products should pass quality tests before they leave our company.

-Diameter inspection

Outer diameter inspection for high quality reduction transmission large modulus gearbox

-Packing and delivery

Delivery of high quality reduction transmission large modulus gearbox usually uses steel frame and plywood to protect important positions. Do you have any good suggestions for this?

4. Our advantages

– More than 30 years of experience in manufacturing precision large non-standard heavy machinery spare parts.

– There are five standardized workshops with a hook of 150 tons.

– Vertical well electric furnace heat treatment- the maximum diameter is 6 meters and the maximum depth is 9 meters.

– Five senior engineers in the field of forging/heat treatment.

– Can provide OEM & ODM, professional e-commerce and technical teams can provide online services.