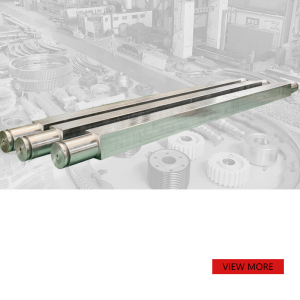

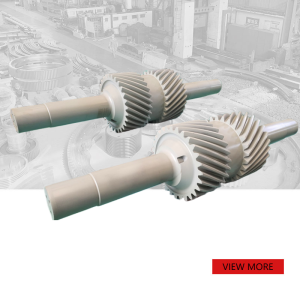

34CrNiMo6Custom Reducer Herringbone Gear Shaft with tool return groove

PRODUCT PARAMETERS

Description

一.Product Description:

We can produce herringbone gear shaft with cutting groove according to the drawings or parameters provided by customers.

Generally used in mining machinery and construction machinery

二.Specification

| Material | Carbon steel, Alloy steel |

| Standard | GOST/DIN/AISI/ASTM/ISO/JIS/GB |

| Module | 8-120 |

| Machining | Lathing-Milling/Hobbing-Grinding |

| Teeth Treatment | Surface hardening,Surface carburizing |

| Heat treatment | QT |

三.Production Process of herringbone gear shaft

- Forging:

Maximum13000 Tons Oil hydraulic press

Through forging, the internal structure of the ingot can be more dense and the mechanical properties are better.

2 .Rough lathing + Rough machining the tooth

When the module≥25,we will add a special procedure-Rough machining the tooth,then after QT,the tooth surface will obtain the best comprehensive mechanical properties

3.UT

In our internal quality control system, 100% UT is performed on every workpiece to ensure that each product has no internal defects

4.QT

We have our own heat treatment workshop.

All of 6 sets of equipment are well-electric furnace and complete quenching medium(Oil,Salt water, Water, Sythetic quenching medium)

5.Finish lathing+Milling

Milling teeth according to product specifications. Milling gear product quality is better.

6.Surface hardening

According to the product requirements and the different materials,

In order to improve the surface hardness and wear resistance, surface hardening or surface carburizing will be carried out.

7.Inspection

When the product are finished, our QC team will carry out inspection and provide customers with dimensions reports, chemical composition reports and mechanical properties reports

四.Company Introduction

— 40+ years production experiences

— 50+ sets of equipments

–6 sets of well-type electric furnaces

–Exported to 50+ contries and regions

— 40+ patents

五.FAQs

- Can you produce gear shafts without cutting groove? –Yes.

- What kind of packing do you have? –Our packing is suitable for export, usually plywood cases.

- Can you issue the drawings?–We can according to customer’s parameters to issue the drawings.

- Do you accept third party inspection?–Yes.