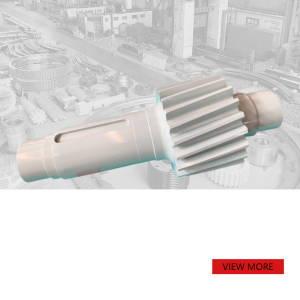

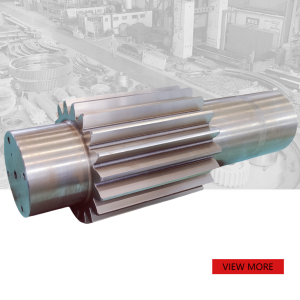

Custom forged 4140 steel helical gear shaft for ball mill

PRODUCT PARAMETERS

Description

1. Product description

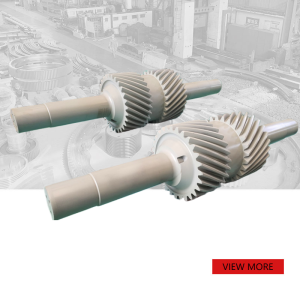

We can produce different kinds of gear shafts, such as spur gear shafts, helical gear shafts, herringbone gear shafts, and even some large module gear shafts. The modules can be M40, M45, M50, etc.

2.Application of gear shafts

Our gear shafts are mainly used as transmission gear parts in industries such as dragline excavators, mills, cement rotary kilns, dryers, etc.

It is mainly used to transmit power. It can transmit the rotation of one shaft to another shaft. Different gear combinations can play different roles, which can realize mechanical deceleration, speed increase, change of direction and reversing, etc. Basically, mechanical devices cannot do without gears.

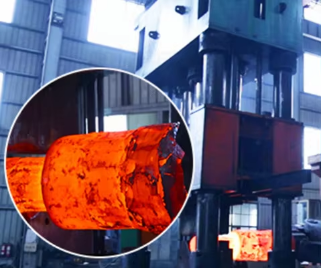

3. Some main production processes of gear shafts

-In the forging step, we design the best forging blank to reduce the cost of raw materials, thereby saving money for customers.

-UT or MT test to check if there are any internal defects. According to this way, we ensure that our raw materials are qualified.

-Heat treatment-quenching and tempering to ensure total hardness.

We can also perform surface hardening and carburizing to improve the surface hardness according to the customer’s drawings.

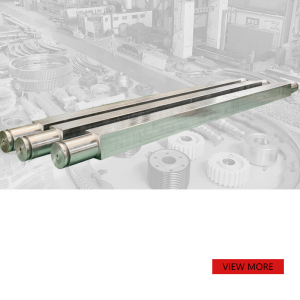

-Gear shaft processing

The forged shaft is ground to ensure its high precision. Especially the journal, so customers can easily assemble the bearing and shaft, and can also use them well together.

The gear teeth will be surface hardened, and the hardness can be HRC45-55.

-Packaging

fumigation-free wooden case customized according to product size. If necessary, a steel frame will be welded to the outside of the wooden box to assist the operation of the forklift truck.

4. FAQs of shaft

-How long is the delivery time? 45-80 days

-What are the packaging methods? According to customer requirements, plywood boxes are generally used.

-Do you accept third-party inspection? Yes

REQUEST A QUOTE

RELATED PRODUCTS

Customized Large Forging shaft for dragline/Walking excavator

Custom mining forging long helical gear shaft

Customized AISI4140 heavy duty hammer crusher Rotor Shaft

Customized forging steel herringbone gear shaft

Customized non-standard Large module gear shaft transimission parts